Liquid spraying device, method and control device on carrier

A liquid spraying and control device technology, applied in the direction of liquid spraying device, spraying device, etc., can solve the problems of reducing spraying efficiency and increasing manpower, and achieve the effect of improving spraying efficiency and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

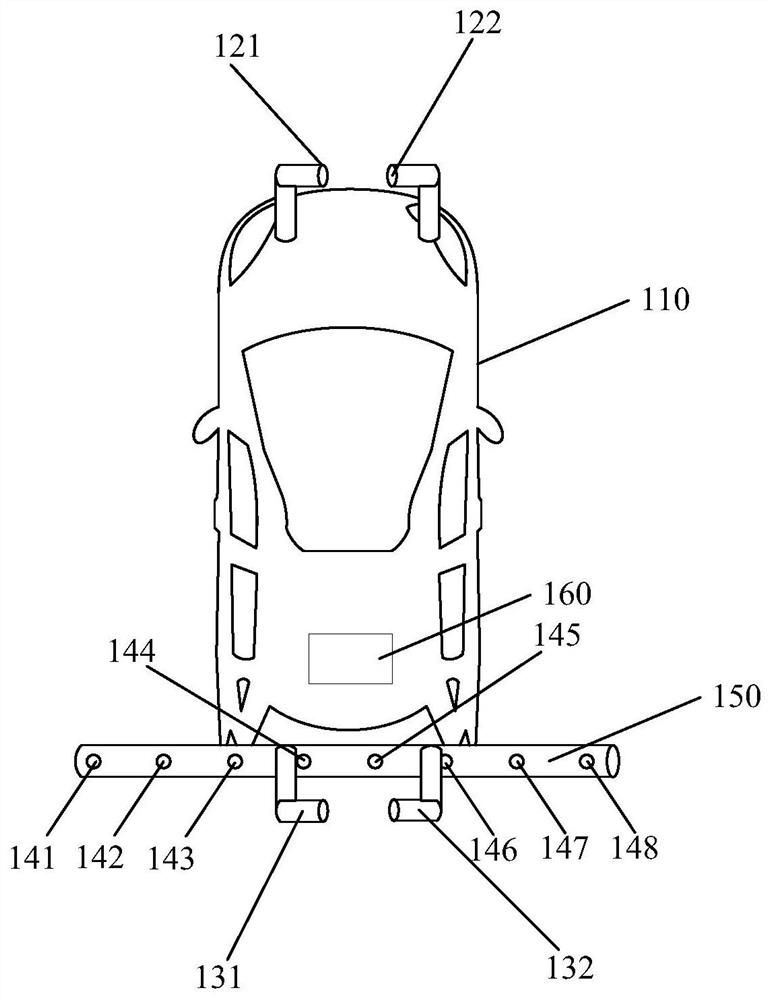

[0052] The liquid spraying method on the carrier provided in this embodiment is as attached Figure 6 As shown, the liquid spray method on the carrier is applied as shown in the attached figure 1 The liquid spraying device on the carrier is shown. See attached figure 1, the liquid spraying device on carrier of this embodiment is mounted on the unmanned vehicle 110, and the unmanned vehicle 110 is also provided with a storage tank (not shown) for storing the liquid to be sprayed. The liquid spraying device on the carrier includes: a first spray port 121 , a first spray port 122 , a second spray port 131 , a second spray port 132 , a humidity monitor 141 to a humidity monitor 148 and a controller 160 . The first spray port 121 and the first spray port 122 are arranged in the front row of the unmanned vehicle 110 (for example, at the front of the vehicle). The second spray port 131 and the second spray port 132 are arranged at the rear of the unmanned vehicle 110 (for example,...

Embodiment approach 2

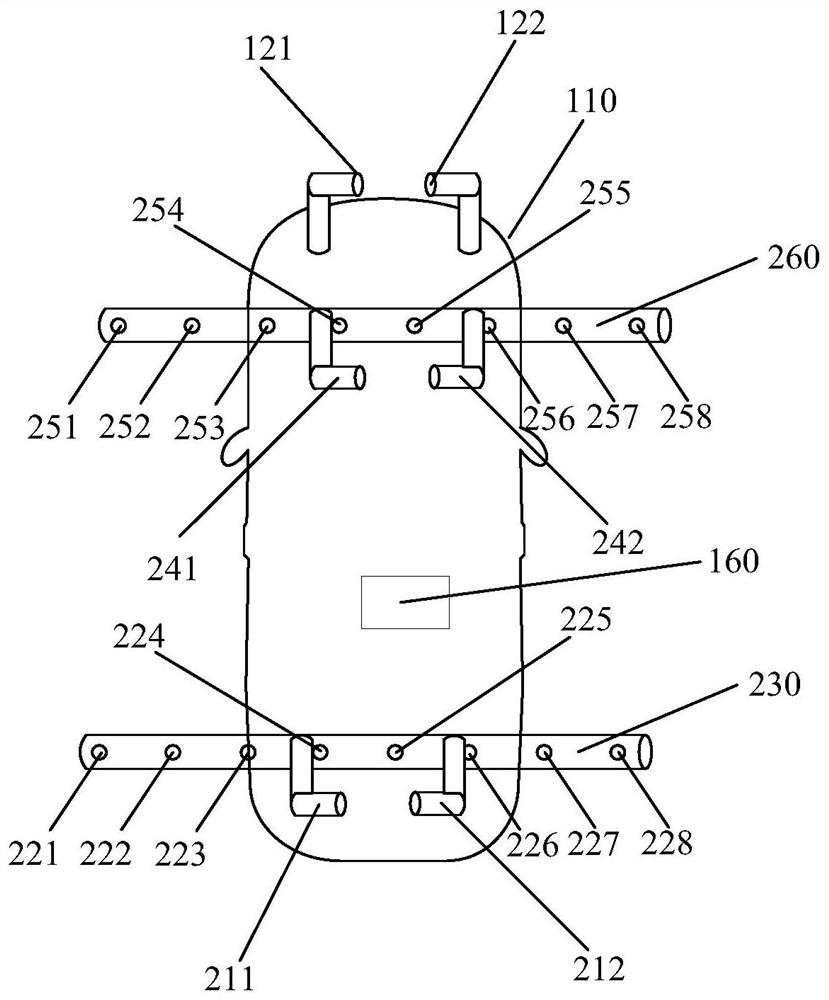

[0064] The liquid spraying method on the carrier provided in this embodiment is as attached Figure 7 As shown, the liquid spray method on the carrier is applied as shown in the attached figure 2 The carrier-on-liquid spraying device is shown. The liquid spraying device on the carrier of this embodiment is mounted on the unmanned vehicle 110, for the convenience of description, the appended figure 2 A simplified schematic diagram of an unmanned vehicle 110 is shown. See attached figure 2 , the liquid spraying device on the carrier of the present embodiment and the attached figure 1 The difference of the illustrated liquid spraying device on carrier is that the liquid spraying device on carrier of the present embodiment includes two sets of humidity monitors (humidity monitor 221 to humidity monitor 228, humidity monitor 251 to humidity monitor 258) and two humidity monitors. A group of second spray ports (second spray port 211 and second spray port 212, second spray por...

Embodiment approach 3

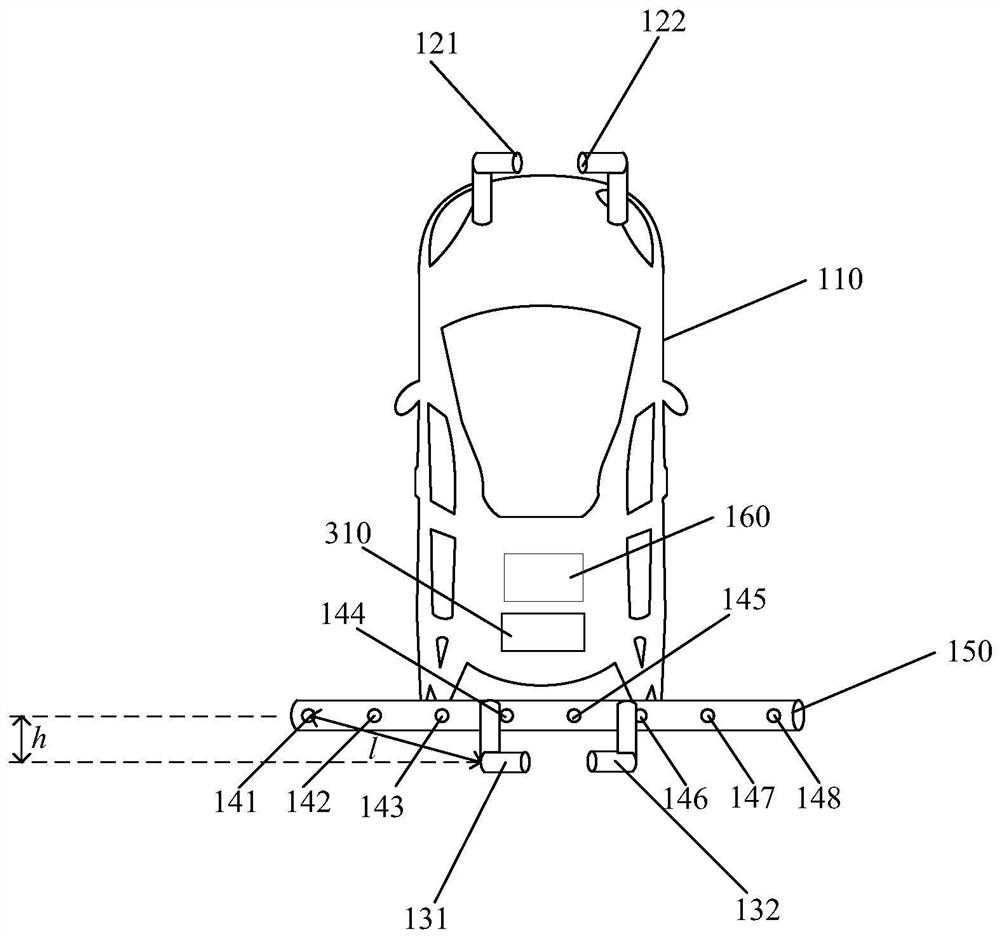

[0075] The liquid spraying method on the carrier provided in this embodiment is as attached Figure 8 As shown, the liquid spray method on the carrier is applied as shown in the attached image 3 The carrier-on-liquid spraying device is shown. The liquid spraying device on a carrier according to this embodiment is mounted on an unmanned vehicle 110 . See attached image 3 , the liquid spraying device on the carrier of the present embodiment and the attached figure 1 The difference of the illustrated liquid-on-carrier spraying device is that the liquid-on-carrier spraying device of this embodiment includes a spraying angle adjuster 310 . It should be noted that the second spray port includes an adjustable spray angle spray head, and the spray angle of the adjustable spray angle spray head can be rotated according to the target spray angle provided by the spray angle adjuster 310 . Or the second spraying port includes a nozzle with a fixed spraying angle, and the second spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com