Wrinkle deviation detection device used by being based on cotton packing films and application method of wrinkle deviation detection device

An offset detection and wrinkle technology, which is applied in transportation and packaging, winding strips, and thin material processing, etc., can solve the problems of reducing the production quality of packaging films, and the packaging films are easy to wrinkle each other and easily produce deviations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

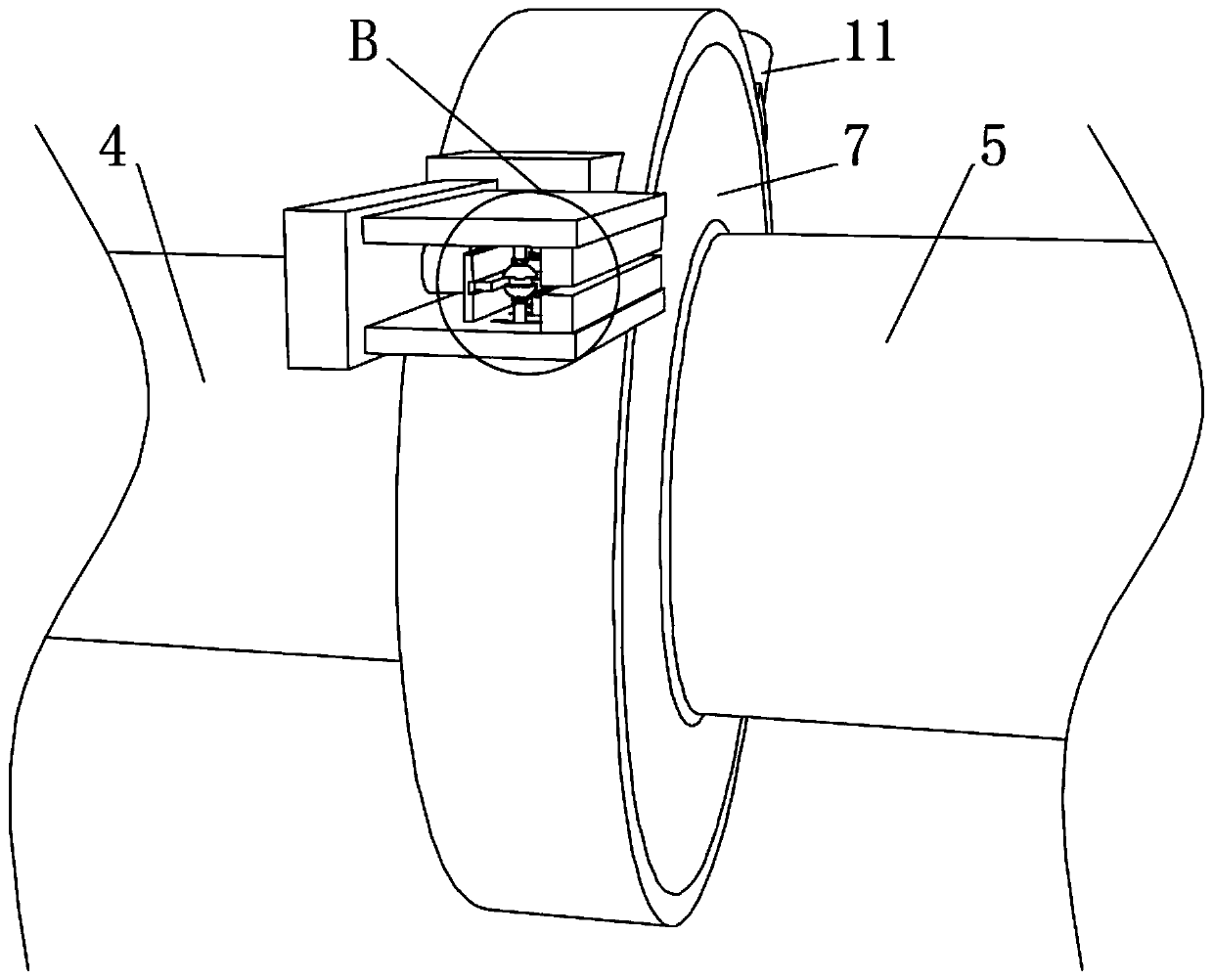

[0043] see Figure 1-8 , a wrinkle deviation detection device based on cotton packaging film, comprising a winding device main body 1, a pair of driving boxes 2 are fixedly connected to the upper end of the winding device main body 1, a servo motor 3 is installed in one of the driving boxes 2, two One end of drive box 2 that is close to each other is all fixedly connected with outer fixed column 4, is provided with rotating column 5 between two outer fixed columns 4, and the output end of servo motor 3 runs through drive box 2 and outer fixed column 4 and is connected with rotating column 5 Fixed connection, two outer fixed columns 4 close to each other end are drilled with an annular groove 6, the inner wall of the annular groove 6 is fixedly connected with a transparent plate 7, and the upper and lower inner ring walls of the annular groove 6 are equipped with a plurality of uniformly distributed ultraviolet irradiation lamps 8. The transparent plate 7 is located outside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com