High-concentration wastewater reduction electro-Fenton tank structure convenient to disassemble, assemble and clean

A technology of high-concentration wastewater and electrophoresis, which is applied in water/sewage treatment, special compound water treatment, oxidized water/sewage treatment, etc., can solve the problems of many silt deposits, easy generation, and difficult to remove silt from precipitation, etc., to achieve Easy to move and easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

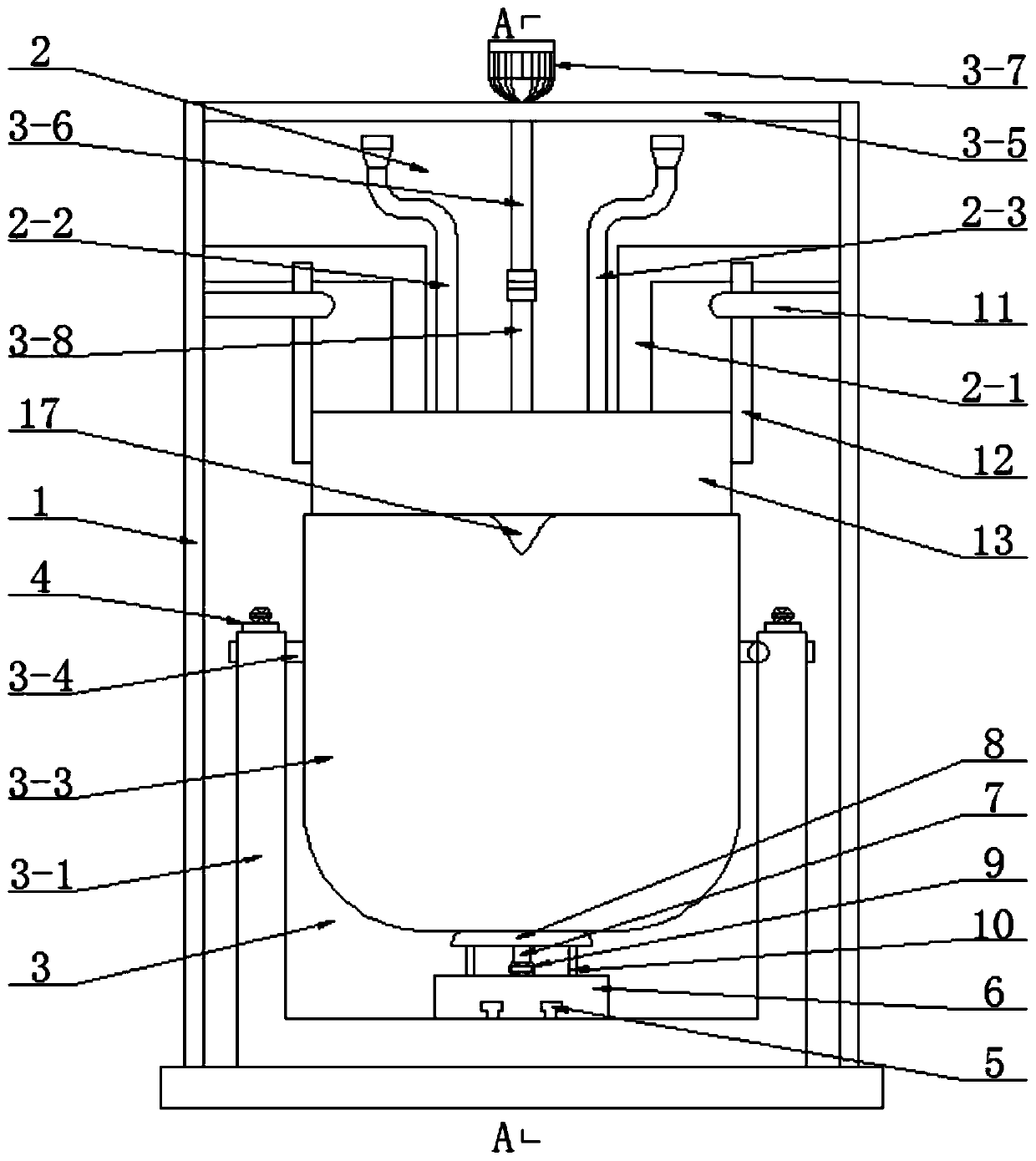

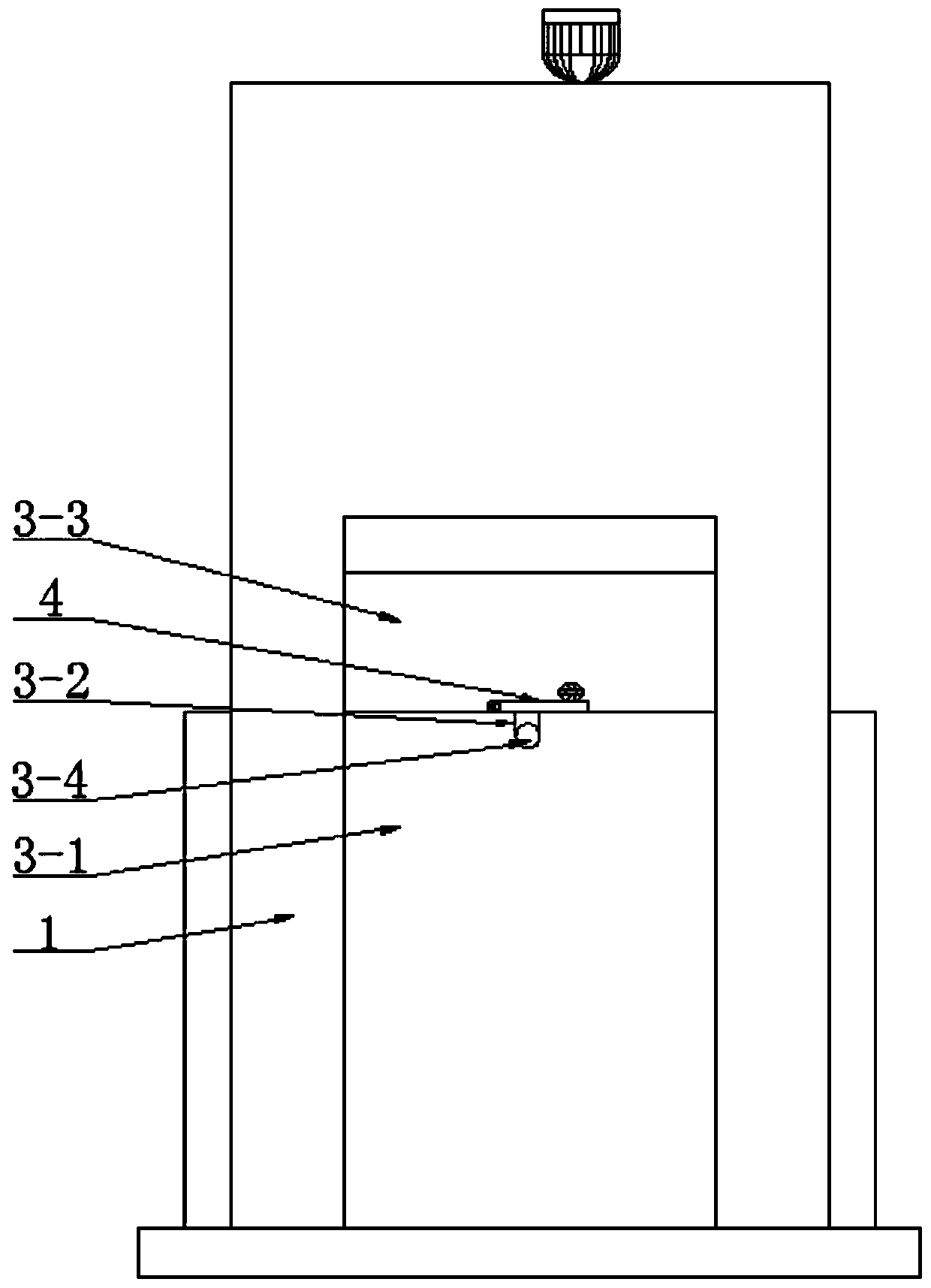

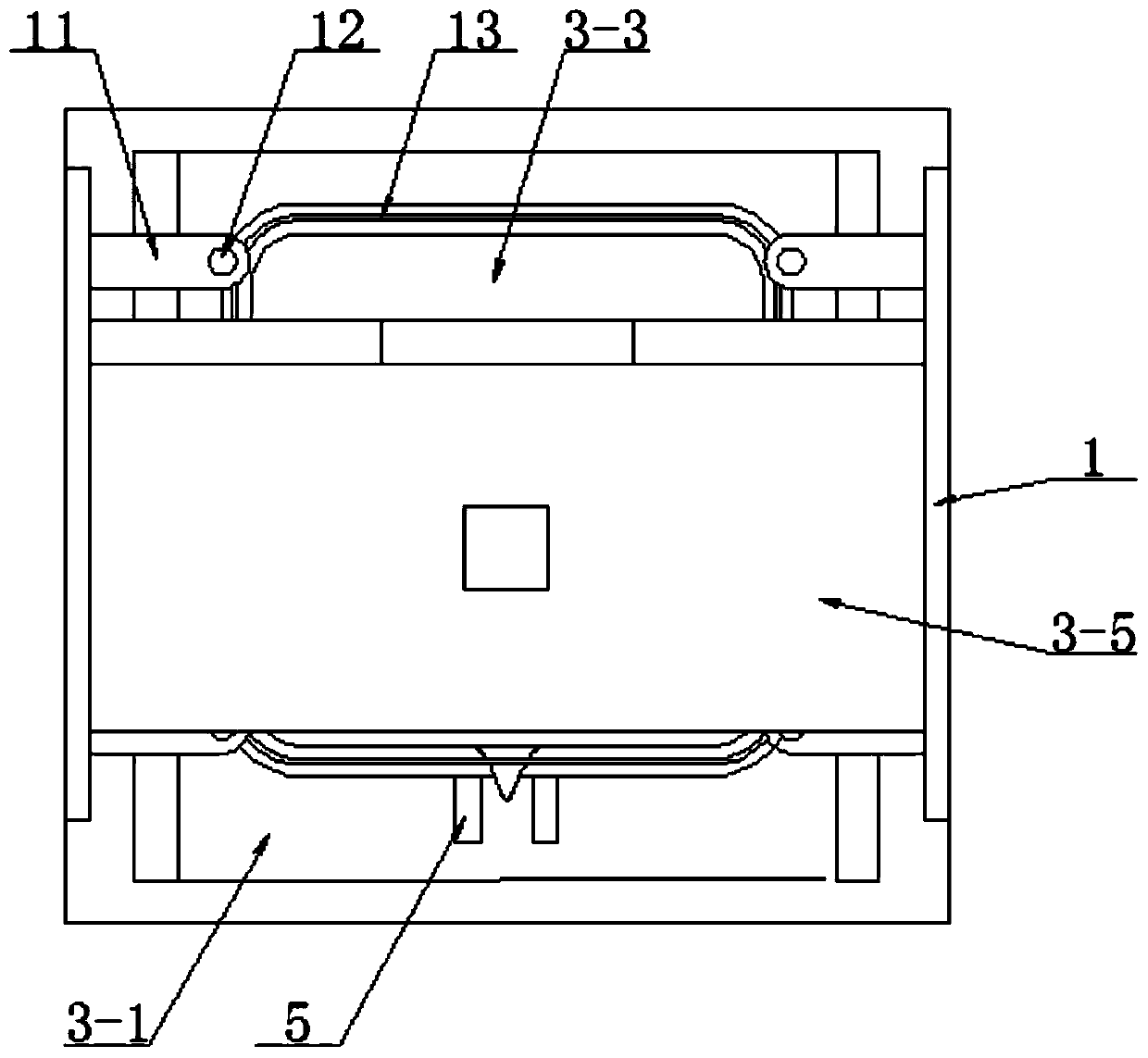

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] see as Figure 1-Figure 4 As shown, this specific embodiment comprises a feeding assembly 2, a stirring assembly 3, and a support 1, wherein the support 1 is riveted and fixed on the ground, the feeding assembly 2 and the stirring assembly 3 are all arranged in the support 1, and the feeding assembly 2 is arranged on the stirring above the inlet end of module 3;

[0026] The feeding assembly 2 includes a mounting seat 2-1, a water inlet pipe 2-2, and a feeding pipe 2-3, wherein the mounting seat 2-1 is welded on the bracket 1, and the left side of the mounting seat 2-1 passes through A water inlet pipe 2-2 is fixed, and a feed pipe 2-3 is fixed on the right side of the installation seat 2-1. The outlet ends of the water inlet pipe 2-2 and the feed pipe 2-3 are all inserted into the stirring Inside component 3;

[0027] The stirring assembly 3 includes a base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com