Electric push bolt type escape door lock

An electric push and escape door technology, applied in the field of escape door locks, can solve the problems of low cost performance and market promotion value, door locks cannot be opened and closed normally, and affect the rapid escape of personnel, etc., and achieves high cost performance and market promotion value. Maintenance and care, low lubrication requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

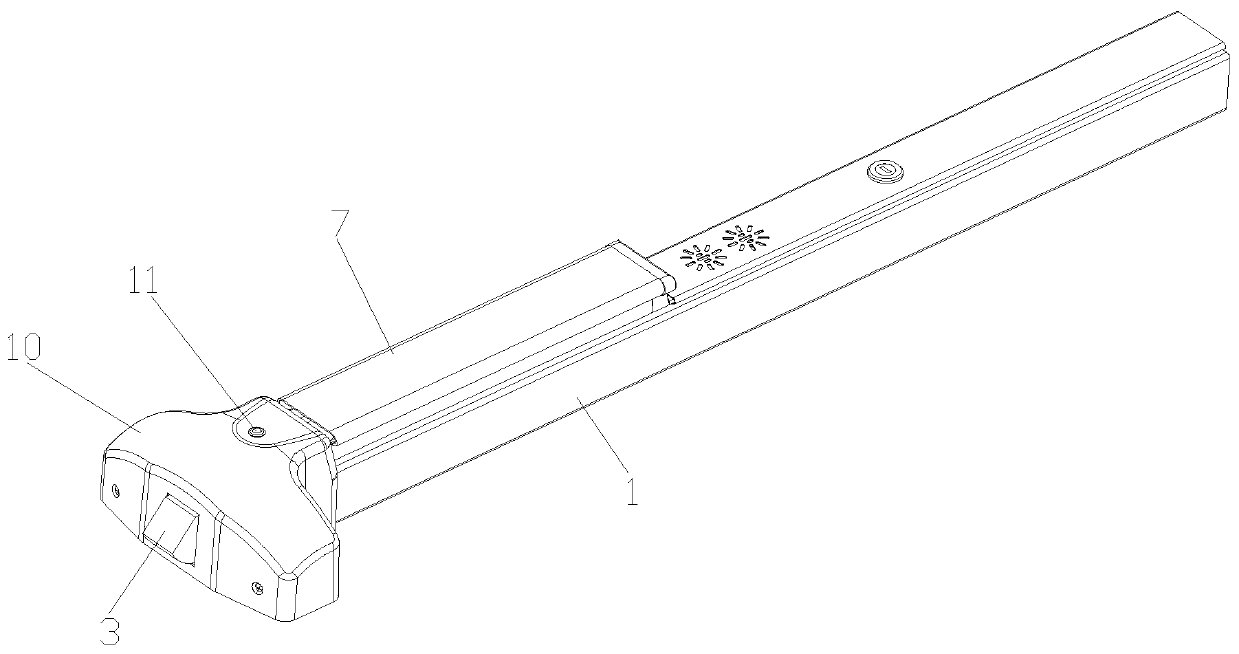

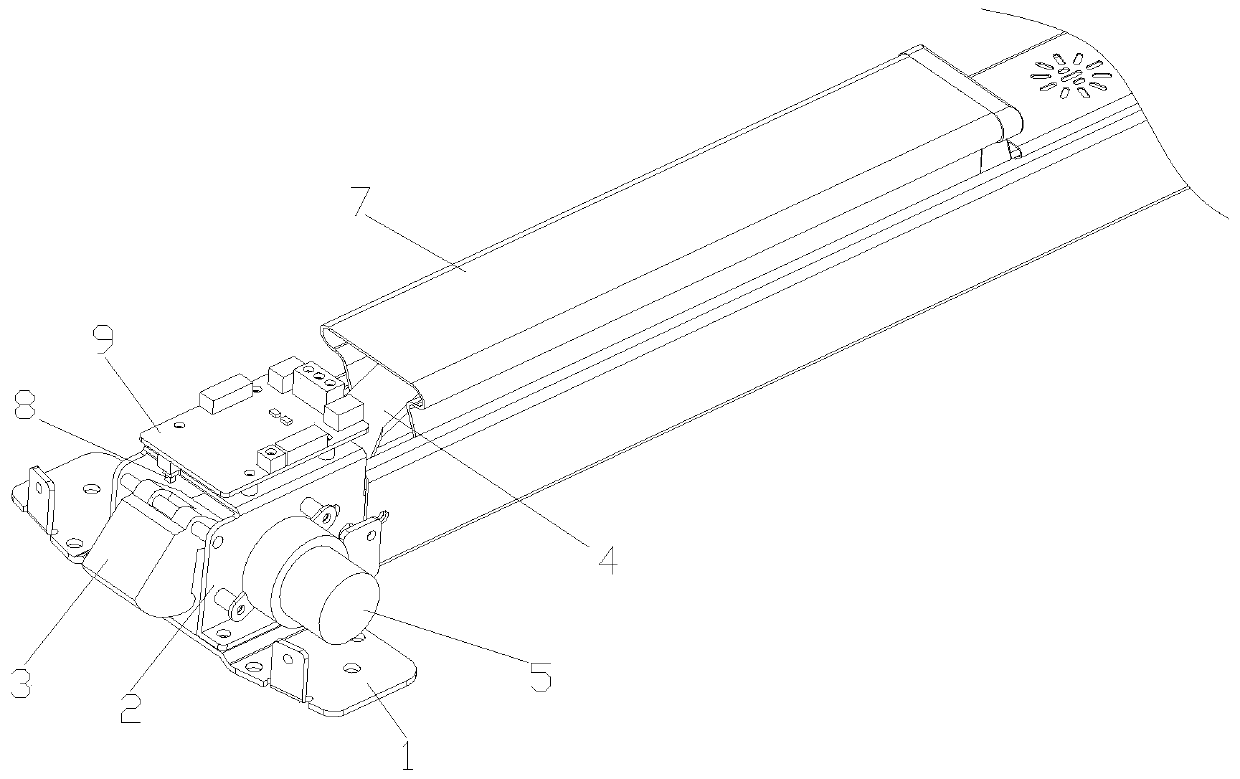

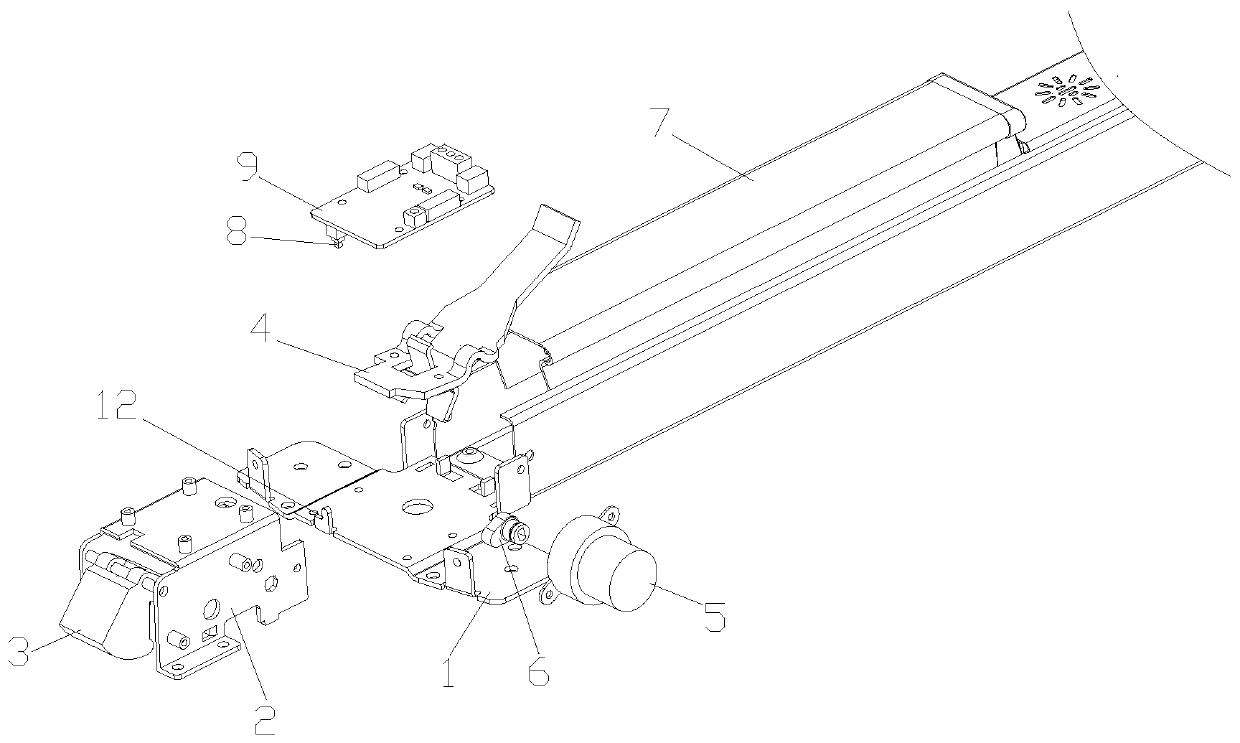

[0049] Such as Figure 1-Figure 7 As shown, an electric push bolt type escape door lock according to the present invention includes a base 1 and a mounting frame 2 arranged on the base 1, a dead bolt 3, a transmission plate 4, a motor 5, a cam 6, a push bolt 7 and Elastic parts (not shown in the figure). The base 1 is roughly in the shape of a "T", and its front end extends to both sides to form a mounting portion for mounting the bolt 3 and other components. The mounting frame 2 is a rectangular frame consisting of a top plate and two side plates. The two side plates are arranged relatively parallel on both sides of the top plate. At the same time, the bottom of the side plates extends to both sides to form a bottom edge, and the bottom edge is installed on the base 1 through bolts. , and then install the mounting frame 2 on the base 1. The deadbolt 3 is installed in the mounting frame 2, specifically, between two side plates and below the top plate. see Figure 6 , The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com