A method for evaluating the self-healing ability of polymer-based self-healing membranes

A self-healing, polymer technology used in testing composite materials, preparation of test samples, material analysis using radiation diffraction, etc. It can solve the difficulty of building multiple precise cracks, and the depth, width and position cannot be precisely controlled. , Research on the limitations of self-healing performance of polymer-based materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

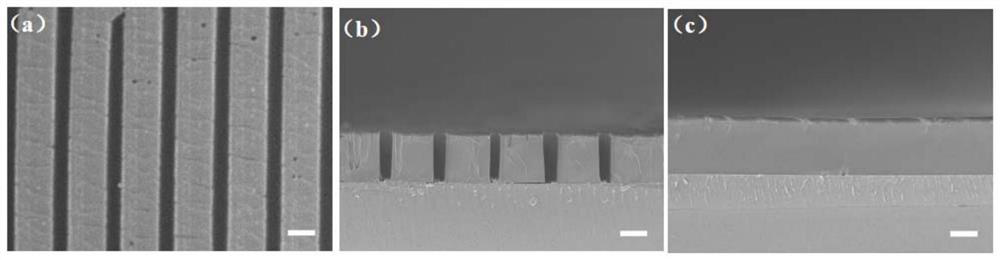

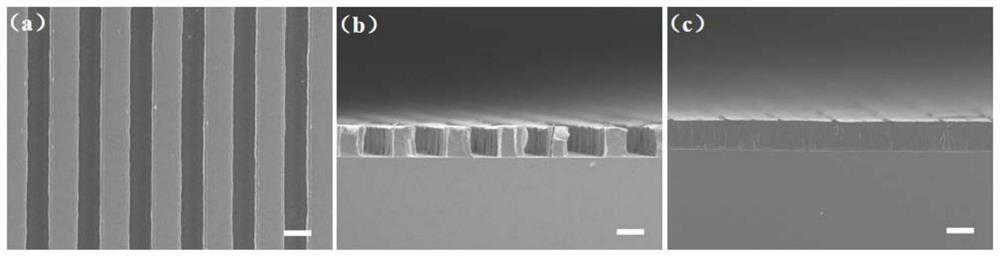

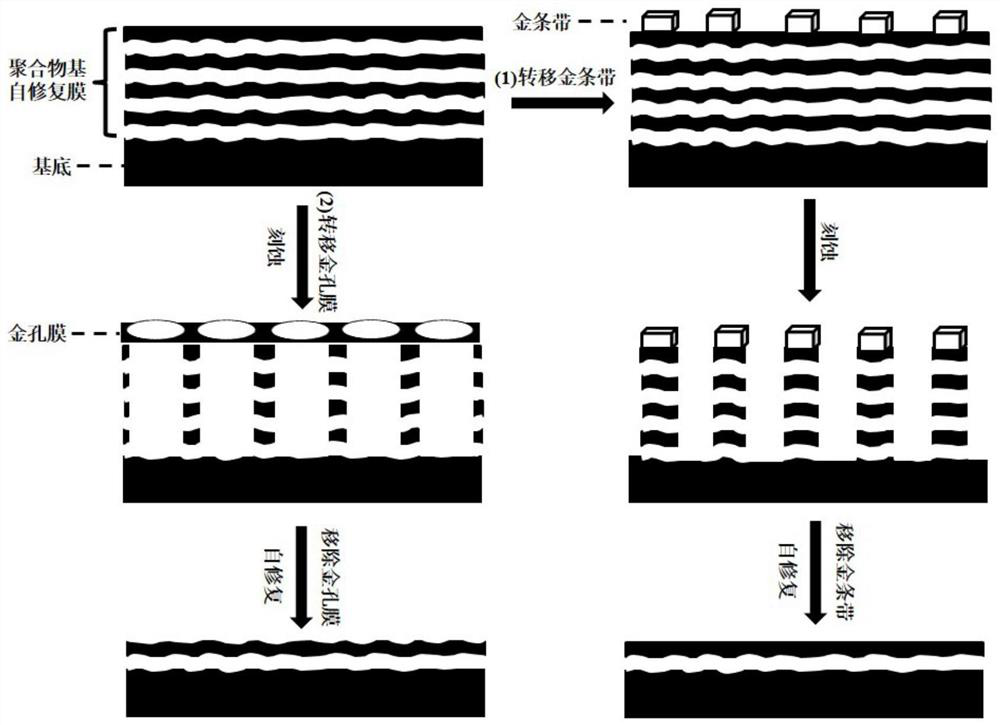

[0068] A method for evaluating the self-healing ability of polymer-based self-healing membranes. Firstly, sample preparation of polymer-based self-healing membranes: use a glass knife to cut branched polyethyleneimine and polyacrylic acid multilayer membranes non-destructively to make the membrane The dimensions are: the thickness of the film is 60 μm, the length is 2 cm, and the width is 2 cm;

[0069] The prepared film was subjected to the etching-self-repairing-measurement process, and the test results were not in compliance, as shown in the table below; among them, the specific crack structure in etching is shown in the table below (the corresponding grade is excellent), and the self-repairing The process is as follows: the etched film is placed in deionized water at a temperature of 20° C. for 30 minutes of self-repair.

[0070] Otherwise, re-select the sample for the process of sample preparation-etching-self-repairing-measurement, and the test results are not in complia...

Embodiment 2

[0075] A method for evaluating the self-healing ability of polymer-based self-healing membranes. Firstly, sample preparation of polymer-based self-healing membranes: non-destructive cutting of branched polyvinylimmonium and polylactic acid multilayer membranes with a glass knife to make the membrane The size is: the thickness of the film is 55 μm, the length is 2 cm, and the width is 2 cm;

[0076] The prepared film was subjected to the etching-self-repairing-measurement process, and the test results were not in compliance, see the table below for details; among them, the specific crack structure in etching is shown in the table below (the corresponding grade is excellent), and the self-repairing The process is as follows: the etched film is placed in deionized water at a temperature of 25° C. for self-repairing for 30 minutes.

[0077] Then, re-select the sample for the process of sample preparation-etching-self-repairing-measurement, and the test results are compliant, see t...

Embodiment 3

[0081] A method for evaluating the self-healing ability of polymer-based self-healing membranes. Firstly, sample preparation of polymer-based self-healing membranes: using a scalpel to cut polyvinyl alcohol-polyacrylic acid self-healing hydrogel electrolyte membranes non-destructively to make the membrane The dimensions are: the thickness of the film is 100 μm, the length is 3 cm, and the width is 3 cm;

[0082] Carry out the process of etching-self-repairing-measurement on the prepared film, the test results are in compliance, see the table below for details; among them, see the table below for the specific crack structure in etching (the corresponding grade is excellent), the process of self-repairing For: the etched film is placed in deionized water at a temperature of 22°C for self-repairing for 30 minutes.

[0083] Then the self-healing ability grade of the polyvinyl alcohol-polyacrylic acid self-healing hydrogel electrolyte membrane is "excellent".

[0084]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com