A method for evaluating the self-healing limit of polymer-based self-healing membranes

A self-healing, polymer technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problem that there is no way to give the limit of self-healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for evaluating the self-healing limit of a polymer-based self-healing membrane, the specific steps are as follows:

[0044] (1) Pretreatment: Place silica microspheres with a diameter of 800nm hexagonal close-packed on the surface of a branched polyvinylimine and polyacrylic acid multilayer film (thickness of the film is 20 μm, and placed on a silicon substrate) ; The silicon dioxide microspheres are etched by plasma etching technology until they are non-closely packed silicon dioxide microspheres with a diameter of 500nm, and the gap between adjacent microspheres is 300nm;

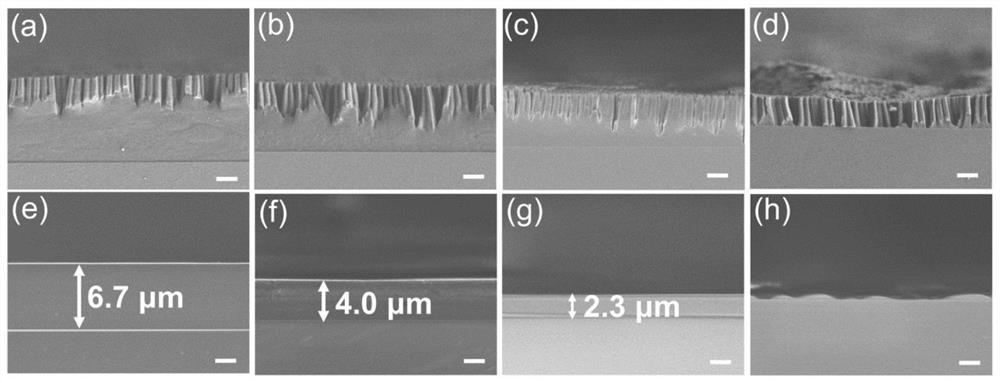

[0045] (2) Etching: the film after step (1) is etched by plasma etching technology to form a specific crack structure (micro-nano column array structure, the diameter of the micro-nano column is 500nm, and the depth is 6 μm); Then, the silica microspheres on the membrane were removed with hydrofluoric acid;

[0046] (3) Self-repair: place the membrane treated in step (2) in deionized wa...

Embodiment 2

[0052] A method for evaluating the self-healing limit of a polymer-based self-healing membrane, the specific steps are as follows:

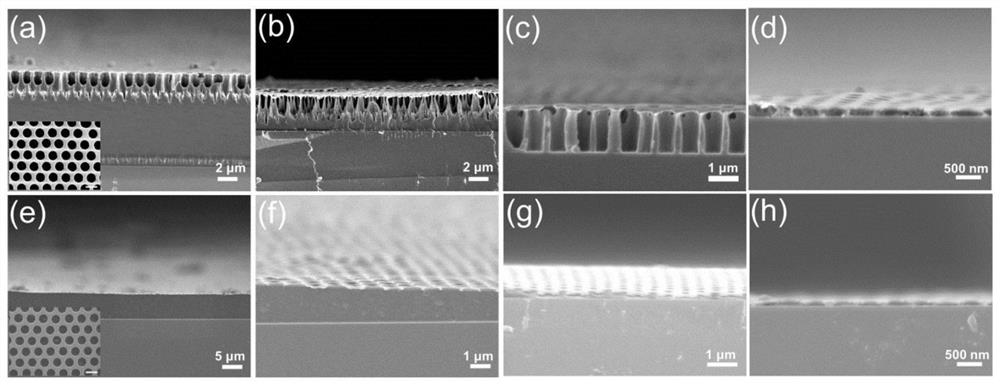

[0053] (1) Pretreatment: Place silica microspheres with a diameter of 500nm hexagonal close-packed on the surface of a branched polyvinylimmonium and polylactic acid multilayer film (thickness of the film is 15 μm, and placed on a quartz substrate); The silicon dioxide microspheres are etched by plasma etching technology until they are non-closely packed silicon dioxide microspheres with a diameter of 300nm, and the gap between adjacent microspheres is 200nm;

[0054] (2) Etching: Etching the film treated in step (1) using plasma etching technology to form a specific crack structure (micro-nano column array structure, the diameter of the micro-nano column is 300nm, and the depth is 3 μm); Then, the silica microspheres on the membrane were removed with hydrofluoric acid;

[0055] (3) Self-repair: place the membrane treated in step (2) in deionize...

Embodiment 3

[0062] A method for evaluating the self-healing limit of a polymer-based self-healing membrane, the specific steps are as follows:

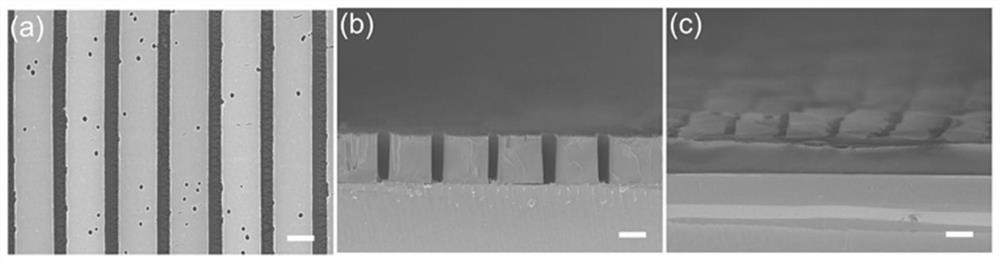

[0063] (1) Pretreatment: Place hexagonal close-packed polystyrene microspheres with a diameter of 5 μm on the surface of polyvinyl alcohol and polyacrylic acid self-healing hydrogel electrolyte membrane (thickness of the membrane is 35 μm);

[0064] (2) Etching: the film after step (1) is etched by plasma etching technology to form a specific crack structure (micro-nano cone array structure, the bottom diameter of the micro-nano cone is 5 μm, and the depth is 4.8 μm) ); Since polystyrene is a polymer, it is etched during the etching polymer process;

[0065] (3) Self-repair: place the membrane treated in step (2) in deionized water at a temperature of 22°C for 30 minutes;

[0066] (4) Measurement: the upper surface roughness value D of the film after the treatment step (3) is measured by an atomic force microscope of JPK instrument AG, Berlin, G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com