Junction line data generation method and junction line data generation system

一种接合线、数据的技术,应用在图像数据处理、黏合鞋部件、制鞋的机械等方向,能够解决无法弹性部件转换、数字模型、没办法精确地产生咬合线等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

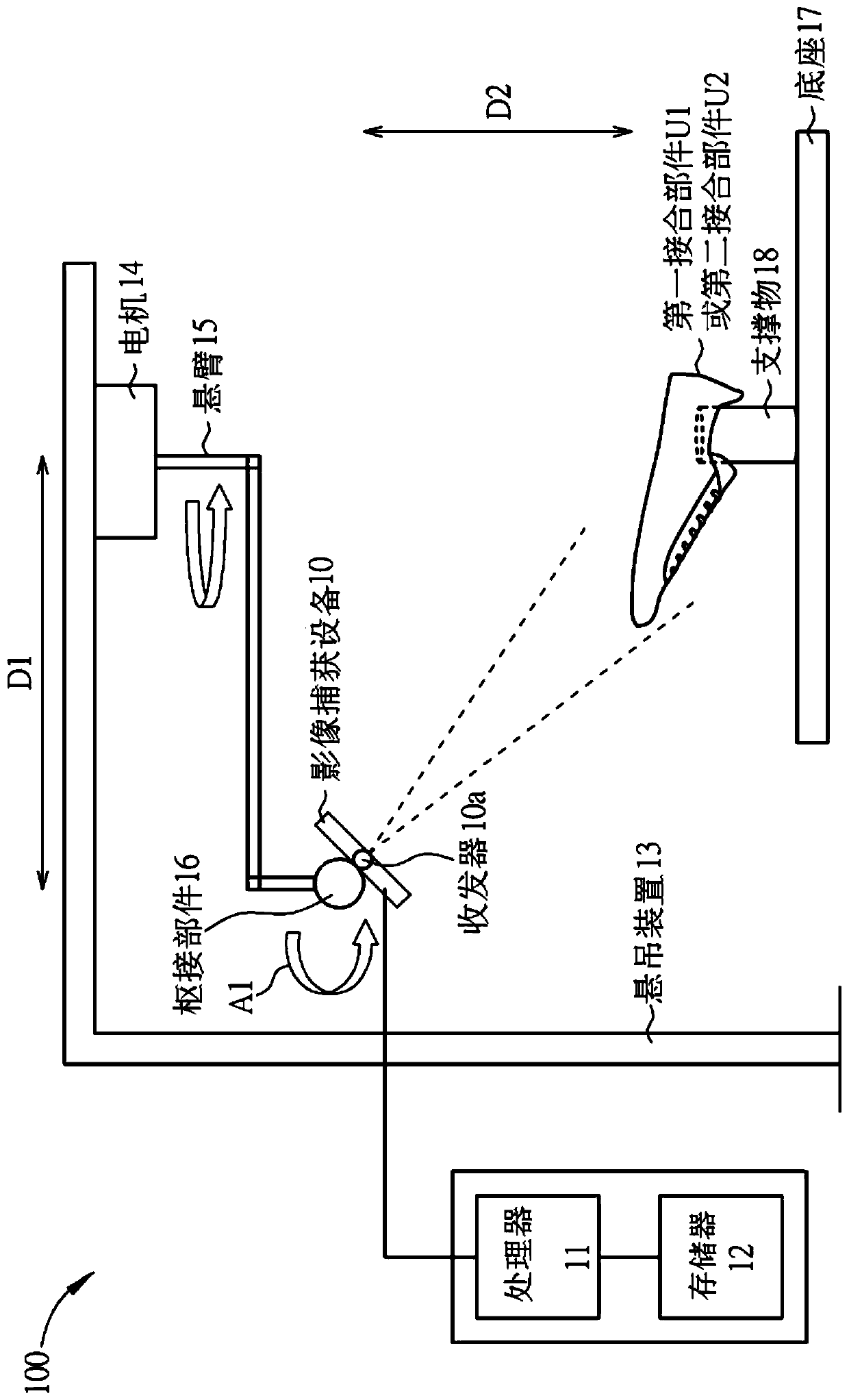

[0019] figure 1 An architecture diagram of the bonding wire data generating system 100 of the present invention. The bondline data generation system 100 may be used to generate bondline data between any two bonded components. In other words, any bonding wire data used for the assembly of two bonded parts can be generated using the bonding wire data generating system 100 . To describe more specifically, the joining line data generation system 100 described below can be applied to a shoemaking production line. Accordingly, the hereinafter mentioned first engaging member may be considered as an upper. The second engaging part may be considered a shoe sole. The seam line data can be regarded as the bite line (Bite Line) data. The upper and the sole can fit closely according to the bite line data. The bonding wire data generation system 100 includes an image capture device 10 , a processor 11 and a memory 12 . The image capture device 10 can be any lens or camera with a photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com