Base section with release lever

A release lever and component technology, applied in the field of base components with a release lever, can solve problems such as time-consuming, release lever drop, shape wear, etc., and achieve the effect of improving finger slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

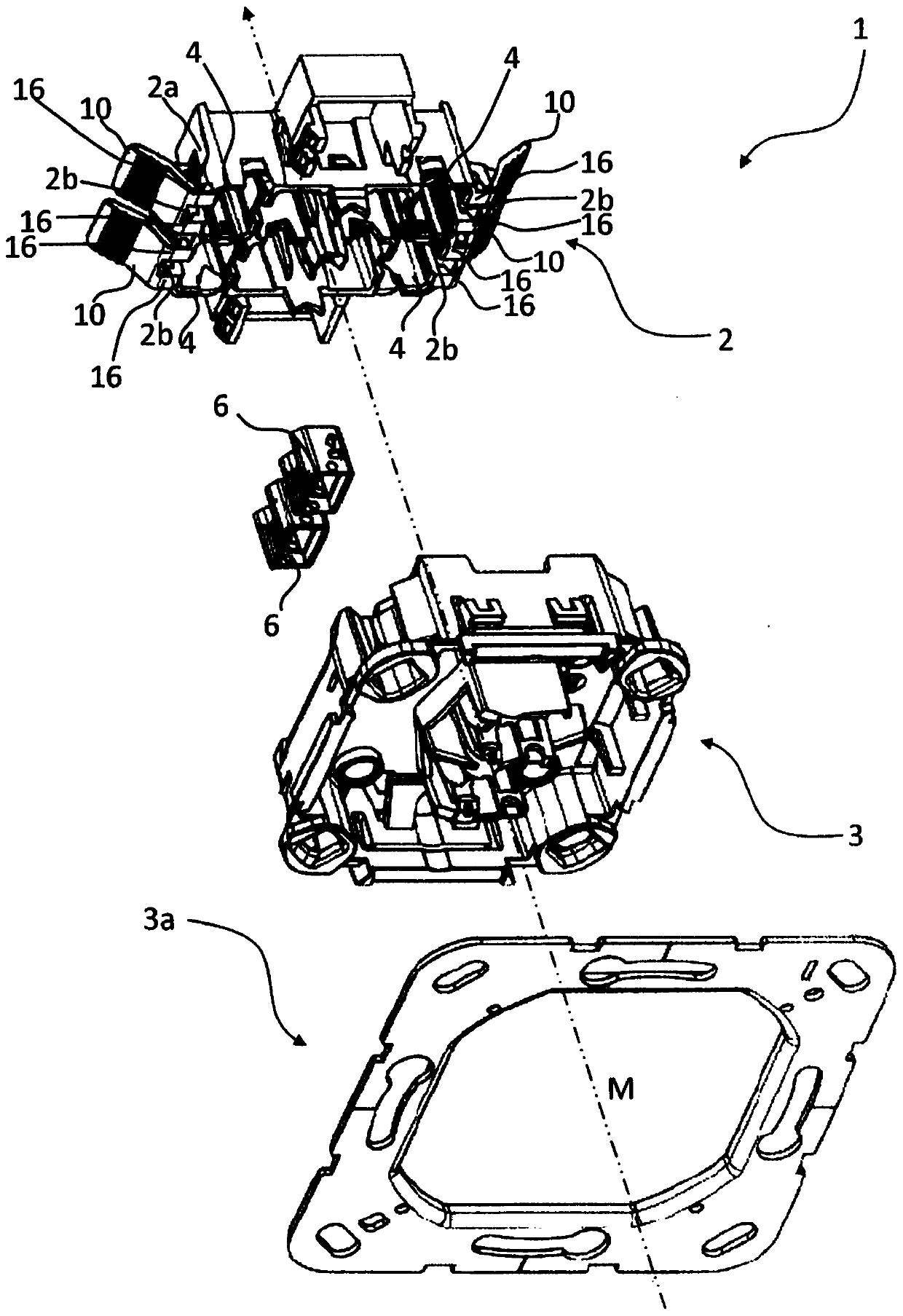

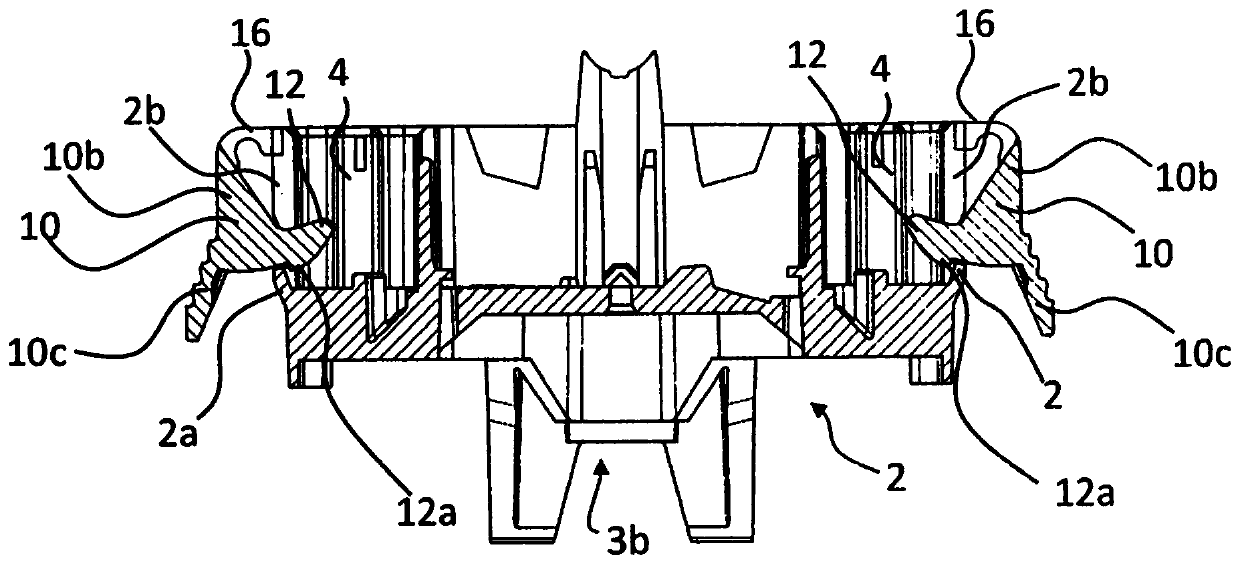

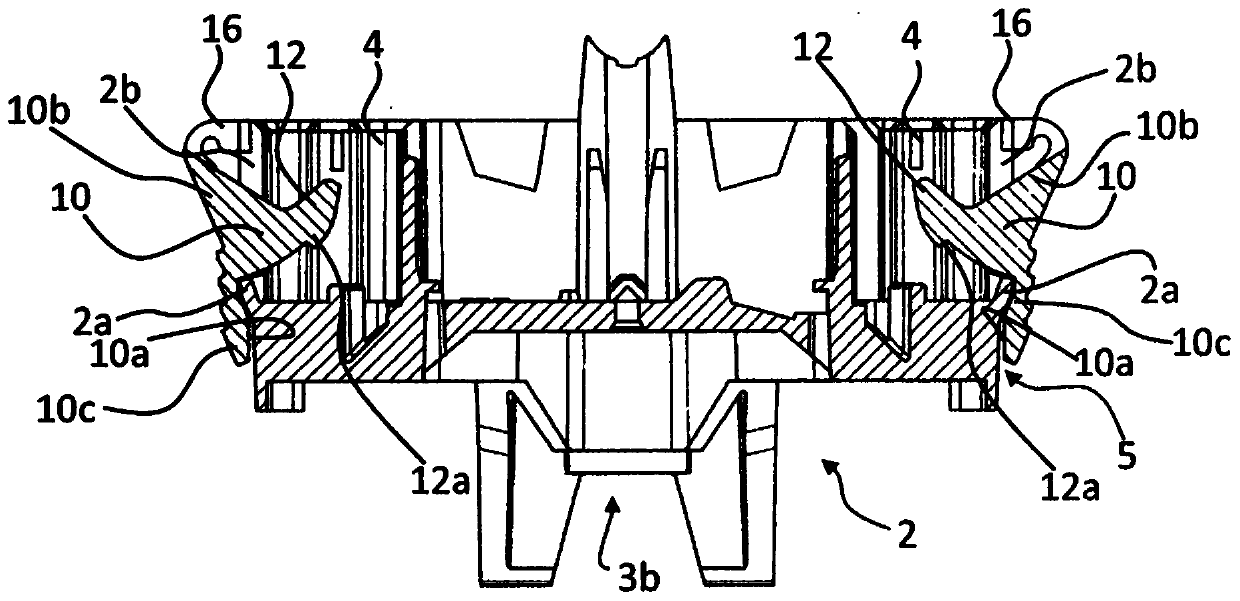

[0031] figure 1 One embodiment of an electrical installation device 1 according to the invention for fitting into a fitting opening is shown, for example a switch or a key. The electronic installation device 1 has a base part 2 which is preferably joined to a base upper part 3 to form a base. This makes it possible in particular to fix the joined base on the support ring 3a. The base upper part 3 has in particular an embossed part The embossment is designed for receiving an operating element (not shown), so that the electronic installation device 1 is especially suitable as a switch or key.

[0032] exist figure 1 The embodiment of the electronic installation device 1 shown in is held in the assembly position inserted into the assembly opening, in particular by means of screws. especially in Figure 4 to Figure 6 The alternative shown in is advantageously held in the assembly opening by means of a jaw bracket. In particular, the claw holder has at least one rotatable cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com