A welding seam tracking and height measurement system for a friction stir welding robot

A welding robot and friction stirring technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of low precision and achieve the effects of data redundancy, high reliability, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the technical solution of the present invention, the following will be described in detail through specific examples:

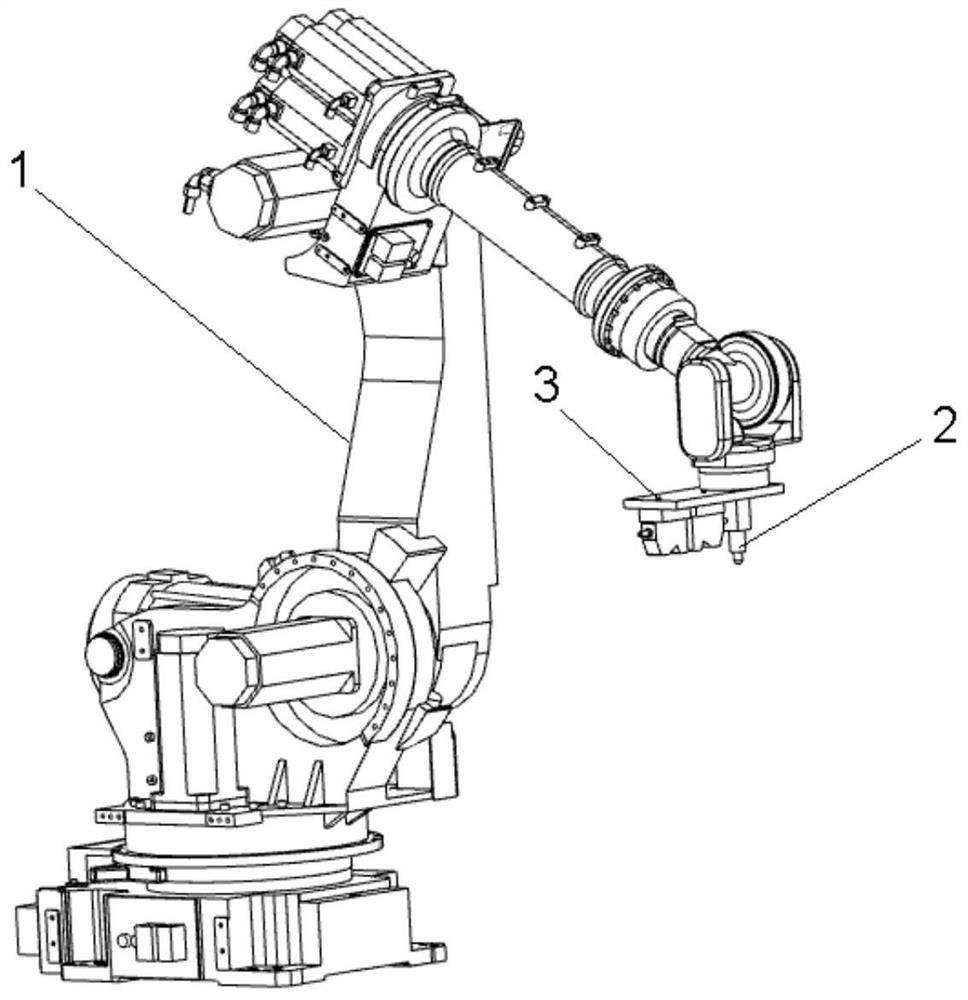

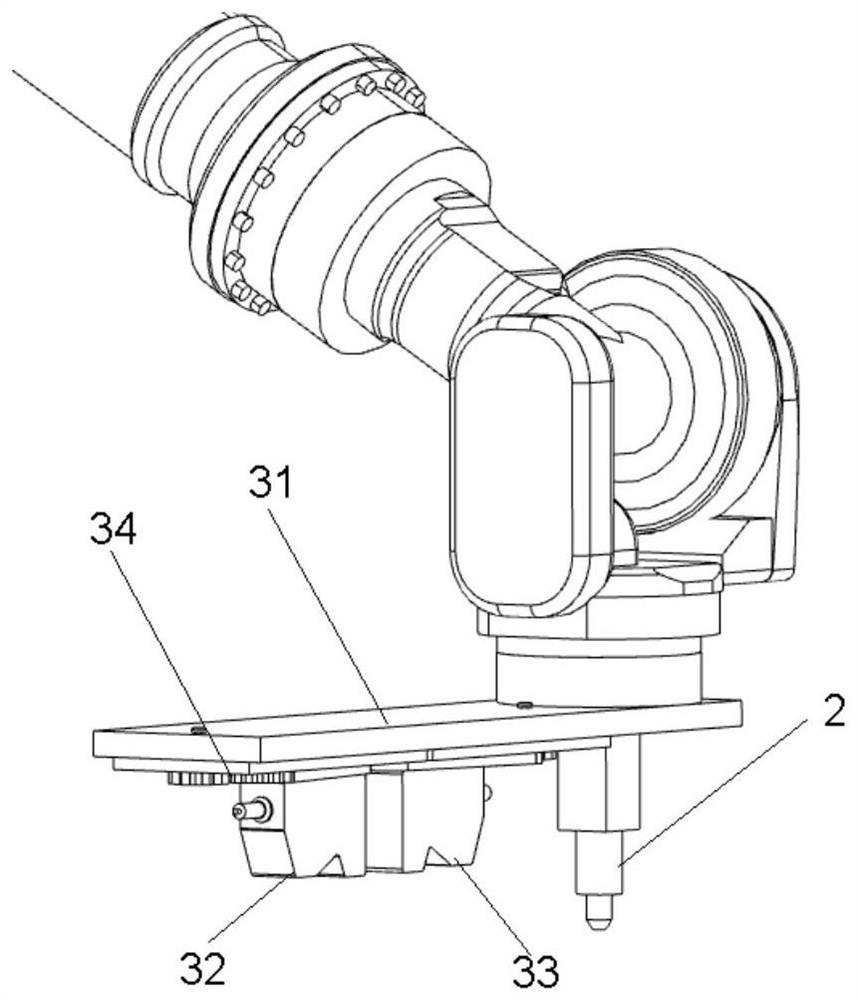

[0020] see Figure 1 to Figure 3 , a welding seam tracking and height measuring system of a friction stir welding robot of the present invention includes a mechanical arm 1, and a stirring head 2 is arranged at the end of the mechanical arm for performing friction stir welding on the welding seam of the working surface. Due to the narrow weld seam of friction stir welding, the stirring head 2 needs to maintain a roughly vertical angle with the working surface during the whole welding operation. When the working surface is an uneven horizontal surface, it is necessary to provide accurate welding seam tracking and stirring head control technology.

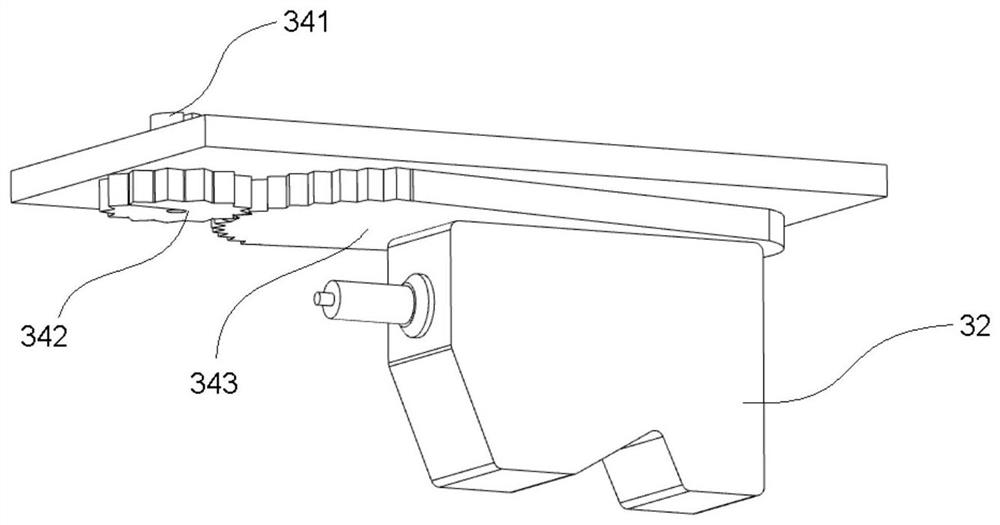

[0021] In the friction stir welding robot seam tracking and height measuring system of the present invention, the stirring head 2 is connected with a dual laser measuring head m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com