Green energy-saving building fabricated wall pouring forming supporting formwork

A prefabricated and architectural technology, applied in the direction of ceramic molding cores, ceramic molding machines, ceramic molding mandrels, etc., can solve unfavorable processing and production of prefabricated walls, affect the quality of prefabricated walls, and damage the corners of walls, etc. problems, to achieve the effect of improving pouring efficiency, high adaptability, and rapid demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

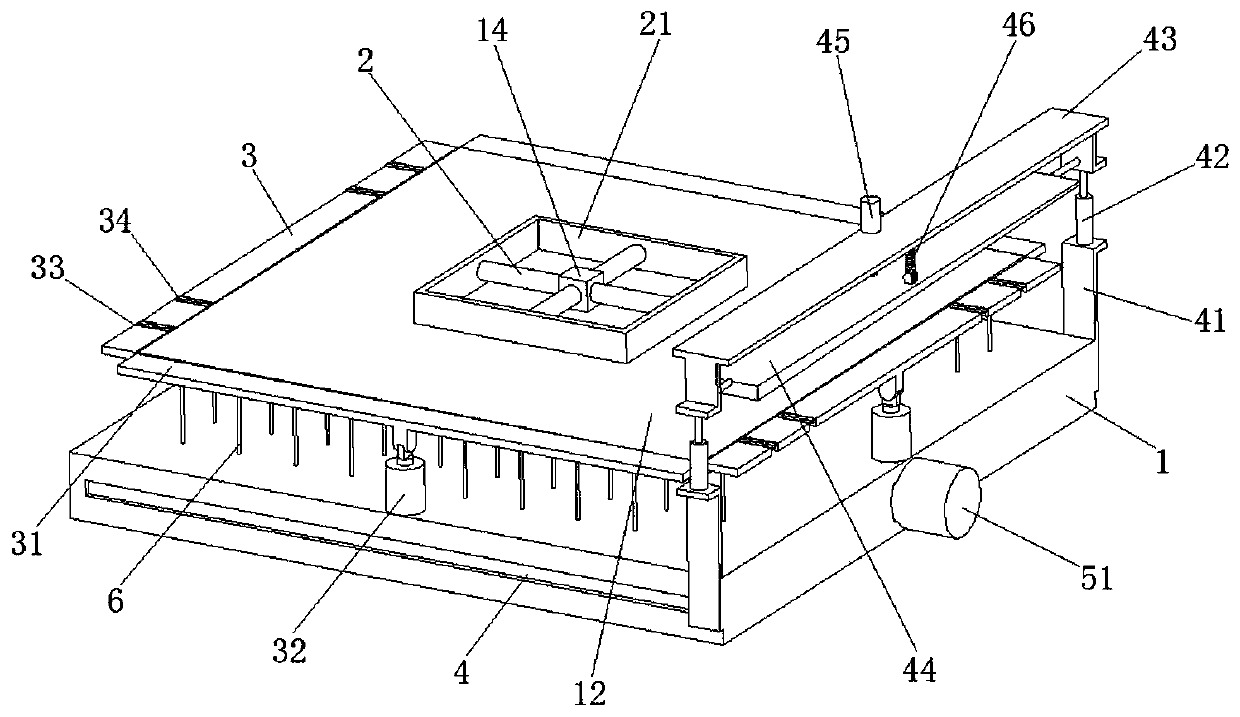

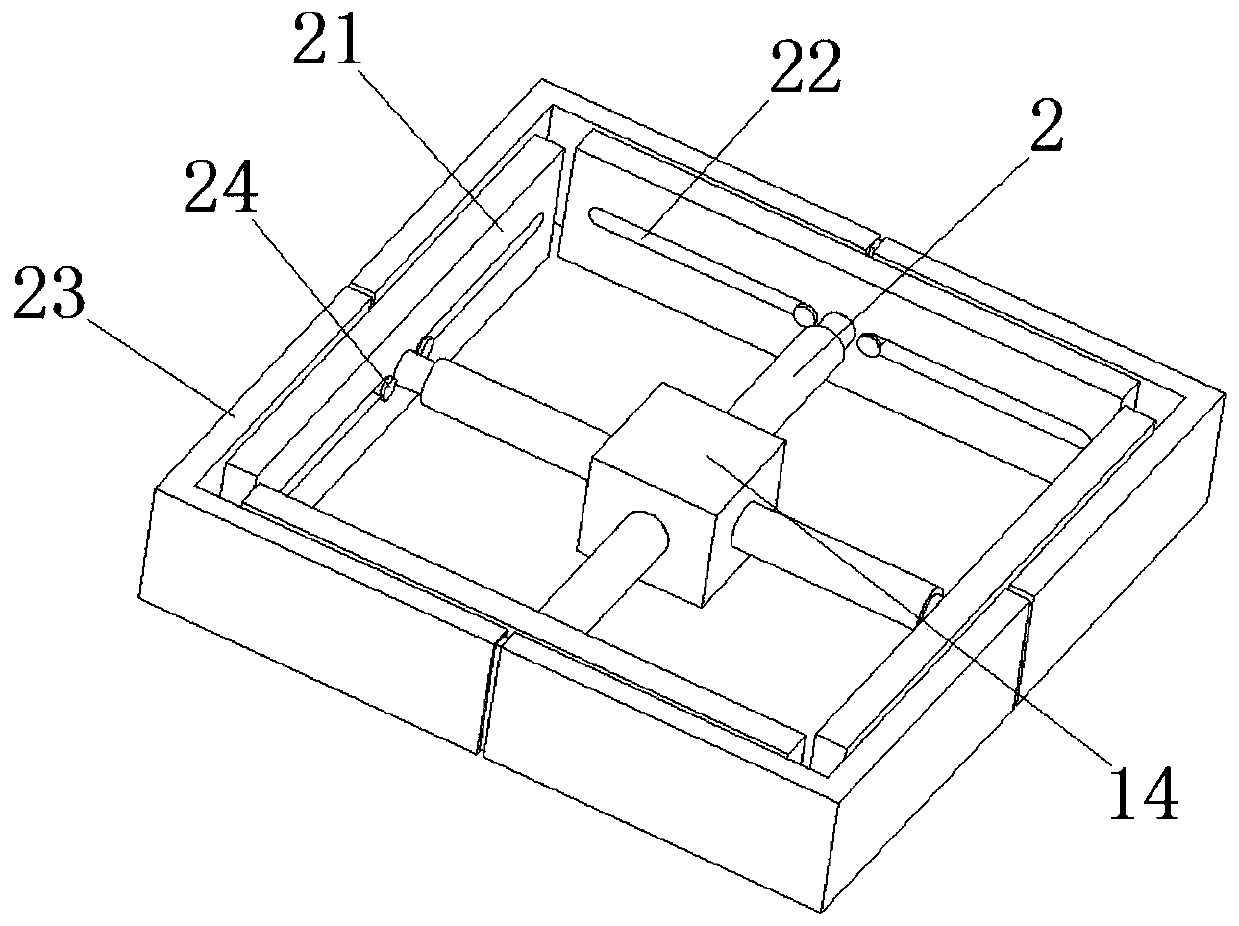

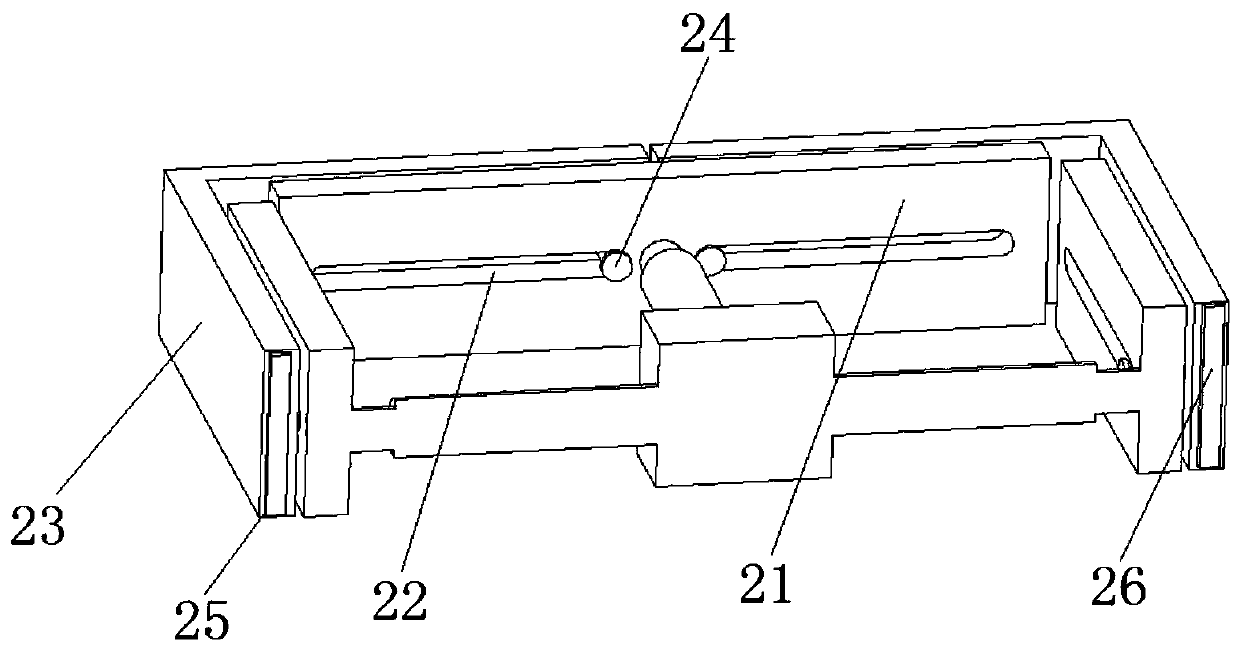

[0026] Such as Figure 1 to Figure 7 As shown, a green energy-saving building prefabricated wall pouring molding support formwork includes a fixed base 1, the top of the fixed base 1 is fixedly connected with a mounting platform 11, and the top of the mounting platform 11 is fixedly connected with a rectangular bottom plate 12. The platform 11 is fixedly connected with a No. 1 hydraulic cylinder 13. The output end of the No. 1 hydraulic cylinder 13 runs through the installation platform 11 and the bottom plate 12 and is fixedly connected with a rectangular connection block 14. The fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap