Writing tool with core breakage preventing function

A writing tool and anti-breaking technology, which is applied to writing utensils, printing, mechanical pencils, etc., can solve the problems of damage to the paper surface, interruption of writing operation, difficulty in use, etc., and achieve the effect of preventing core breakage and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

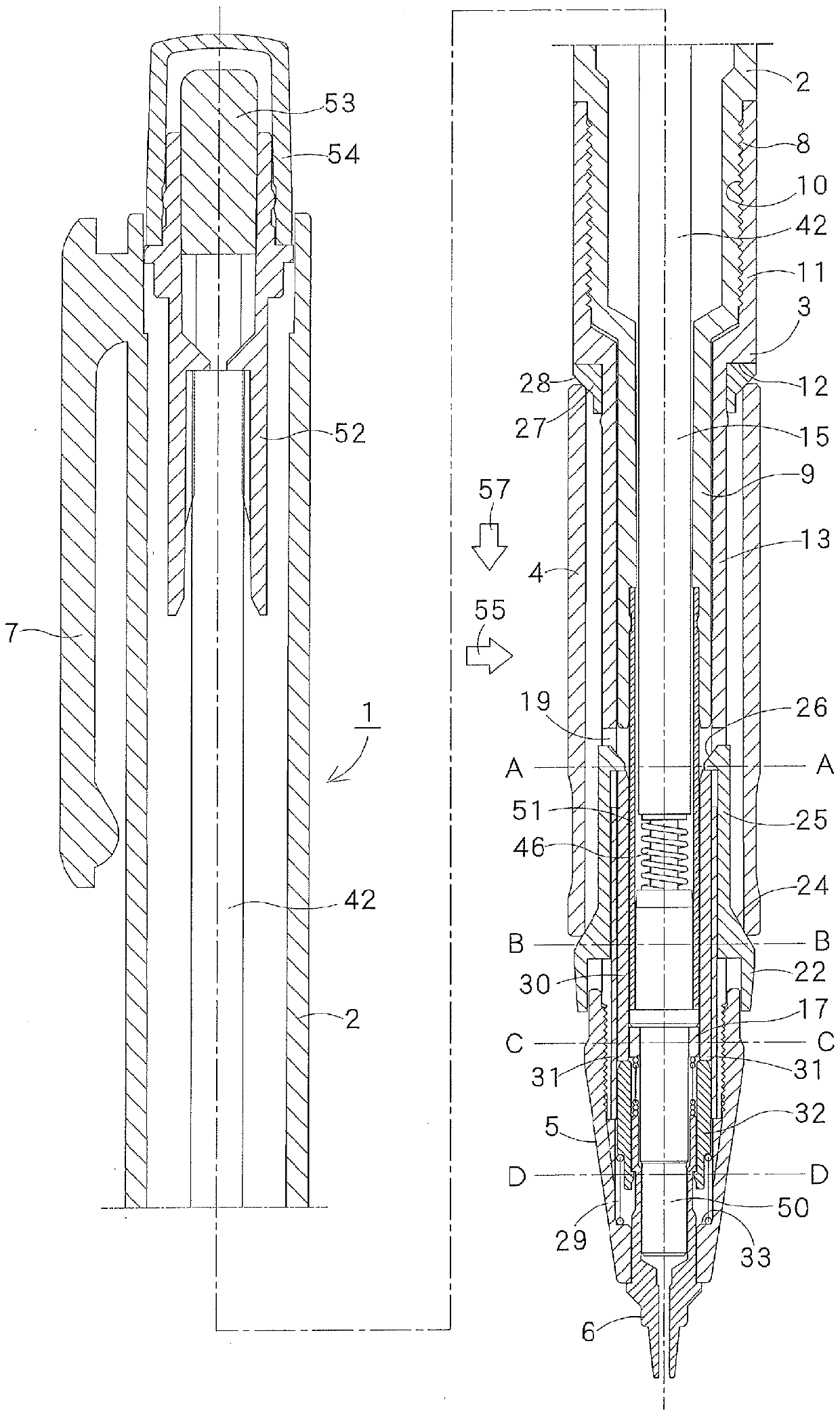

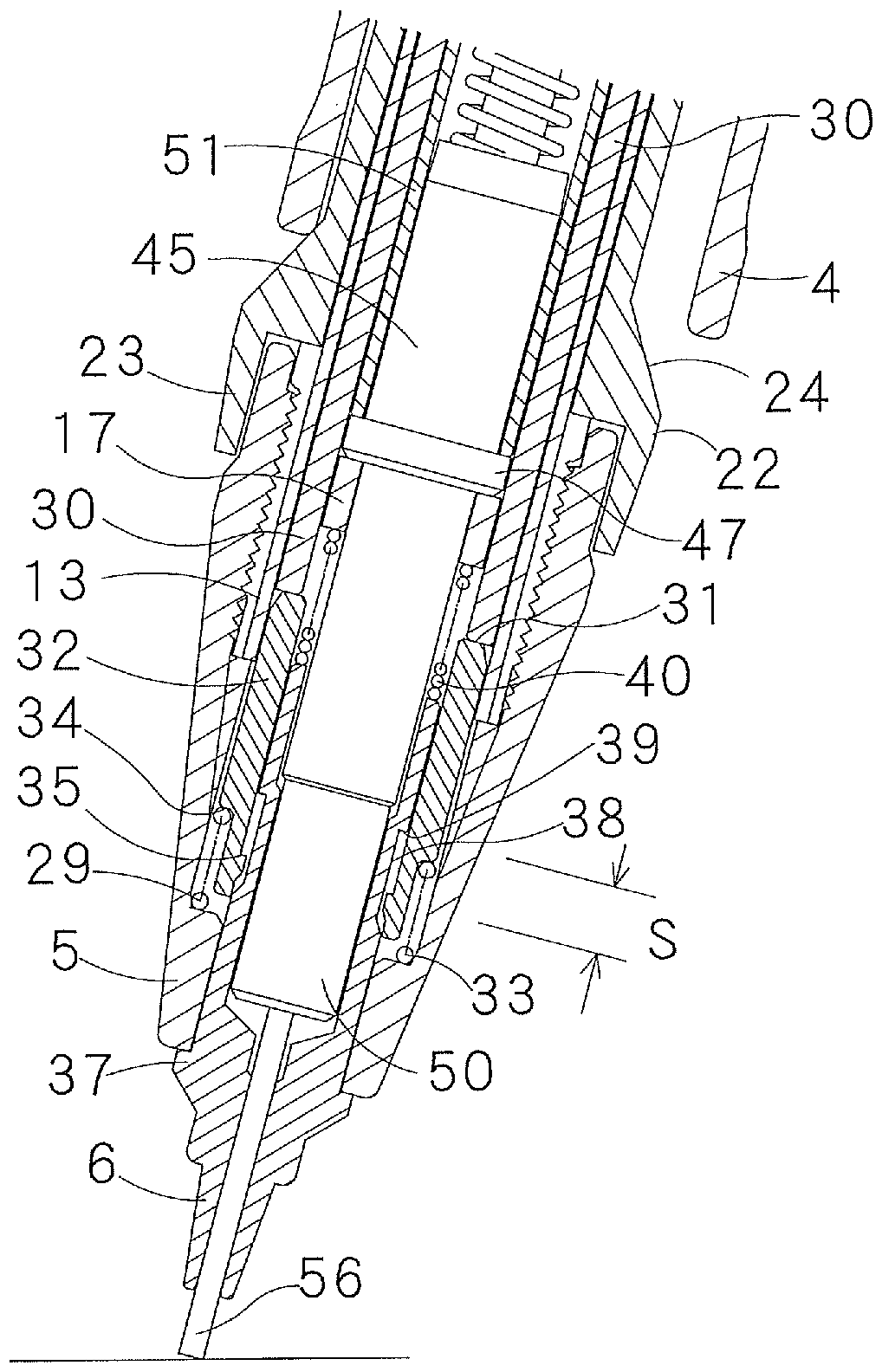

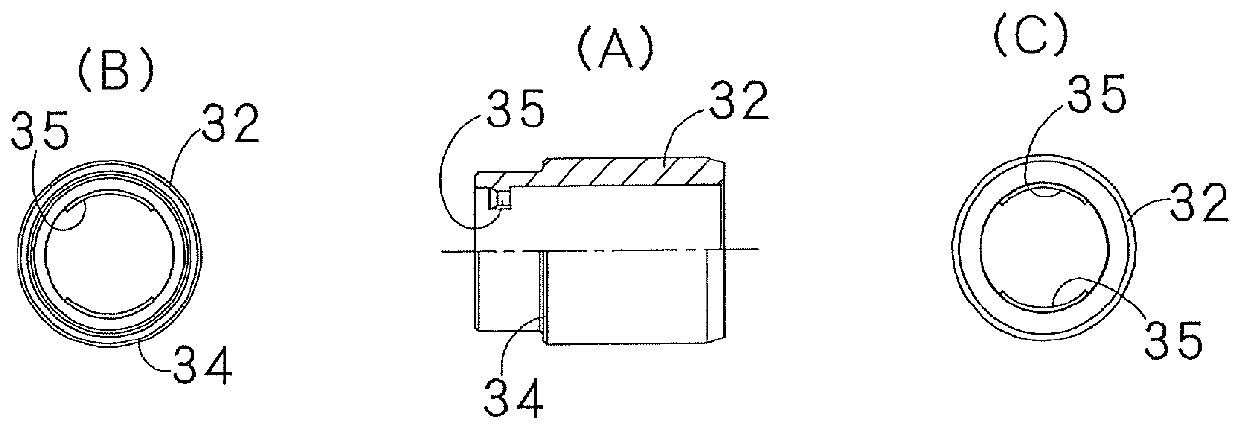

[0060] The present invention can be applied to various writing implements or delivery tools for stick-shaped cosmetic implements, etc. However, in the embodiment shown in the figure, an embodiment applied to a movable pencil as a writing implement will be described. In addition, in this specification, "front" and "top" refer to the direction in which the core is sent out, and "rear" refers to the direction in which the core is submerged. In addition, the axial diameter direction means a direction orthogonal to the axial center of the barrel main body, and the axial length direction means a direction along the axial center.

[0061] Reference figure 1 , figure 2 , The barrel main body 1 is composed of an upper main body 2 and a lower main body 3 connected to the upper main body 2, a grip portion 4 is provided on the outer periphery of the lower main body, and a tapered portion (metal port) 5 is provided at the top end. A sliding member 6 whose contraction can protrude forward and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com