Pencil sharpener capable of automatically discharging broken pencil lead

A technology for automatic rowing and sharpening of pencil sharpeners, applied in printing, office supplies, sharpening devices, etc., can solve the problems of blade wear, trouble, stuck between the blade and the knife holder, etc., and achieve the effect of avoiding manual removal of broken cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

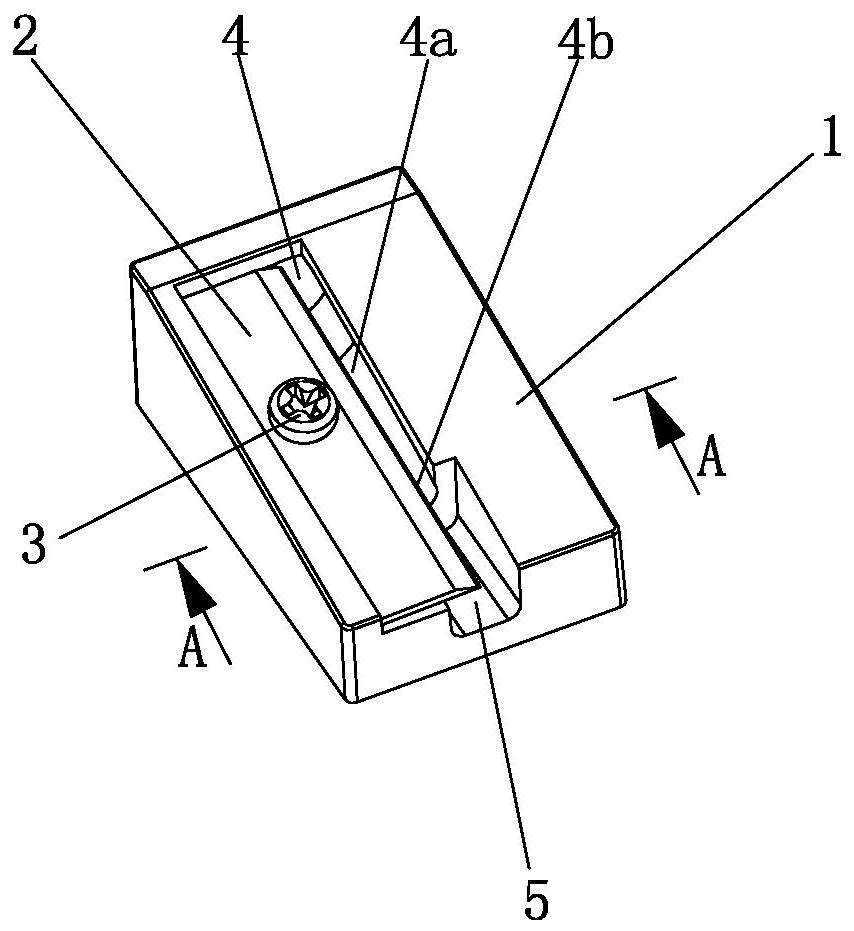

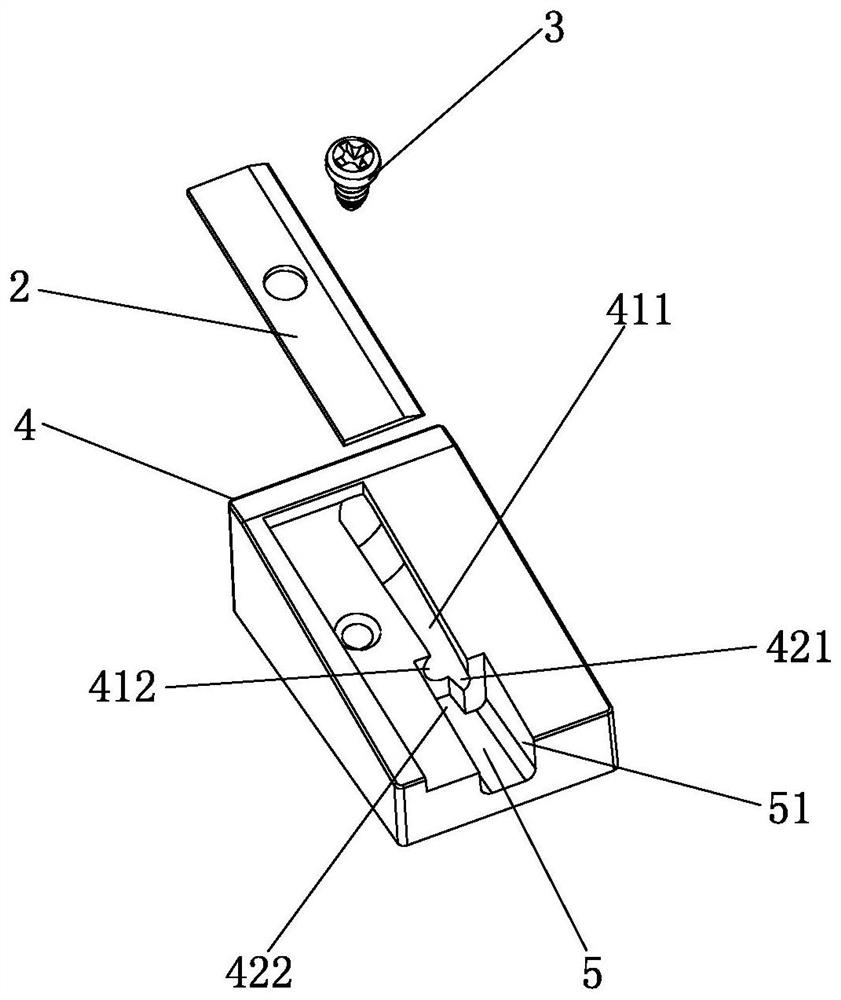

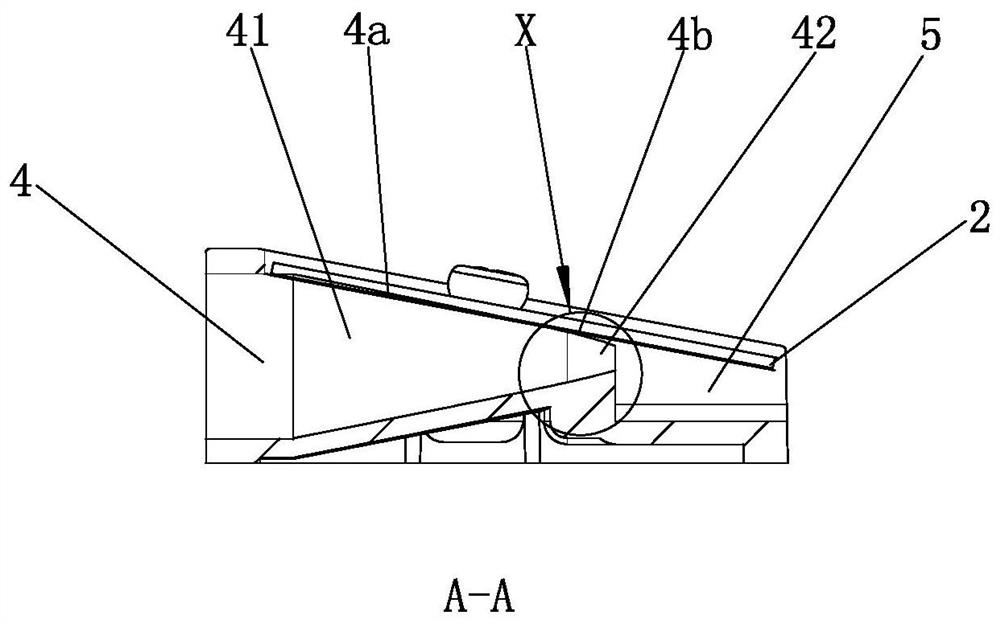

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, a pencil sharpener for automatically arranging pencils and breaking cores includes a knife holder 1, a blade 2 and a fixing screw 3. The blade 2 is fixed on the knife holder 1 by the fixing screw 3, and a core slot 5 is provided on the knife holder 1 And conical sharpening hole 4. The sharpening hole 4 includes a first hole section 41 and a second hole section 42. The second hole section 42 communicates with the end of the first hole section 41, and the end of the first hole section 41 refers to the end away from the opening of the sharpening hole 4. The hole wall of the first hole section 41 includes a first arc wall 411 and a second arc wall 412, and the hole wall of the second hole section 42 includes a third arc wall 421, which is located in the extending direction of the first arc wall 411 Above, a groove 422 is provided on the hole wall of the second hole...

Embodiment 2

[0033] Such as Picture 9 As shown, the core slot 5 is in the extension direction of the second arc wall 412 and a curved surface is formed on the tool holder 1 at the same time, so that the second sharpening section 4b formed is transverse to the axis of the sharpening hole 4 The cross-sectional area gradually increases. The cross-sectional area of the end of the core ejection groove 5 far away from the pencil hole 4 is larger than the cross-sectional area of the end of the core ejection groove 5 near the pencil hole 4. The groove 422 is composed of a curved wall 4221 and a straight wall 4222. The groove wall of the core groove 5 forms a curved surface on the tool holder 1. This curved surface is a part of a conical surface and extends on the curved wall 4221 of the groove 422. On the same cone surface as the curved wall 4221 of the groove 422, the broken core falls into the groove 422 and then the cone surface is used to directly fall out of the pencil sharpener from the ...

Embodiment 3

[0035] Such as Picture 10 As shown, the groove bottom and both sides of the core groove 5 are flush with the three side inner walls of the groove 422, and one side groove wall of the core groove 5 is provided with an inner recess 51, which is in the third In the extending direction of the arc wall 521. The recess 51 is connected to the third arc wall 521 and extends in the extension direction thereof. The cross section of the recess 51 is arc-shaped, and the diameter of the circle corresponding to the arc is smaller than the diameter of the pencil lead to be sharpened, and is between 1.8 mm and 2.0 mm. In this example, the diameter of the circle corresponding to the arc is 1.93 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com