Interface self-detecting high-strength ultrathin anti-bending adhesive tape cable

A wire and cable, high-strength technology, applied in the field of interface self-inspection high-strength ultra-thin anti-bending tape wire and cable, can solve problems such as damaged design, decoration, stumbling and pulling, cable leakage, etc., to improve bending performance, reduce Conductor stress, solving the effect of bending and breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

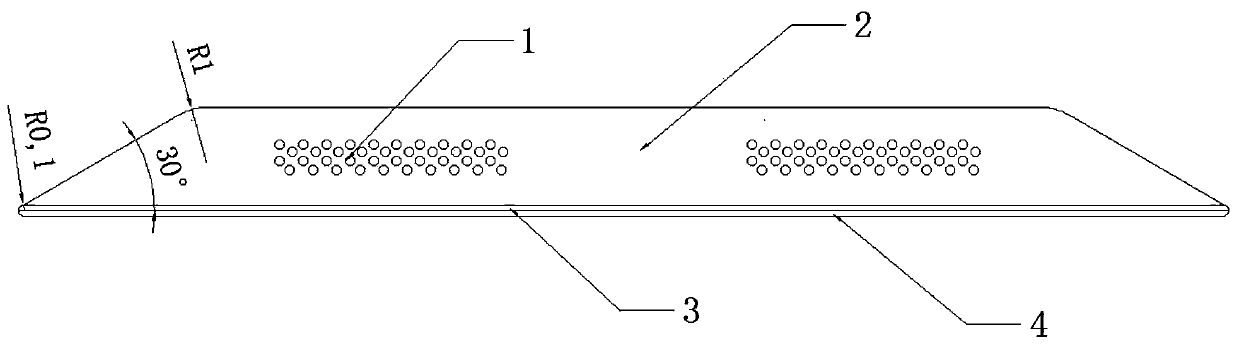

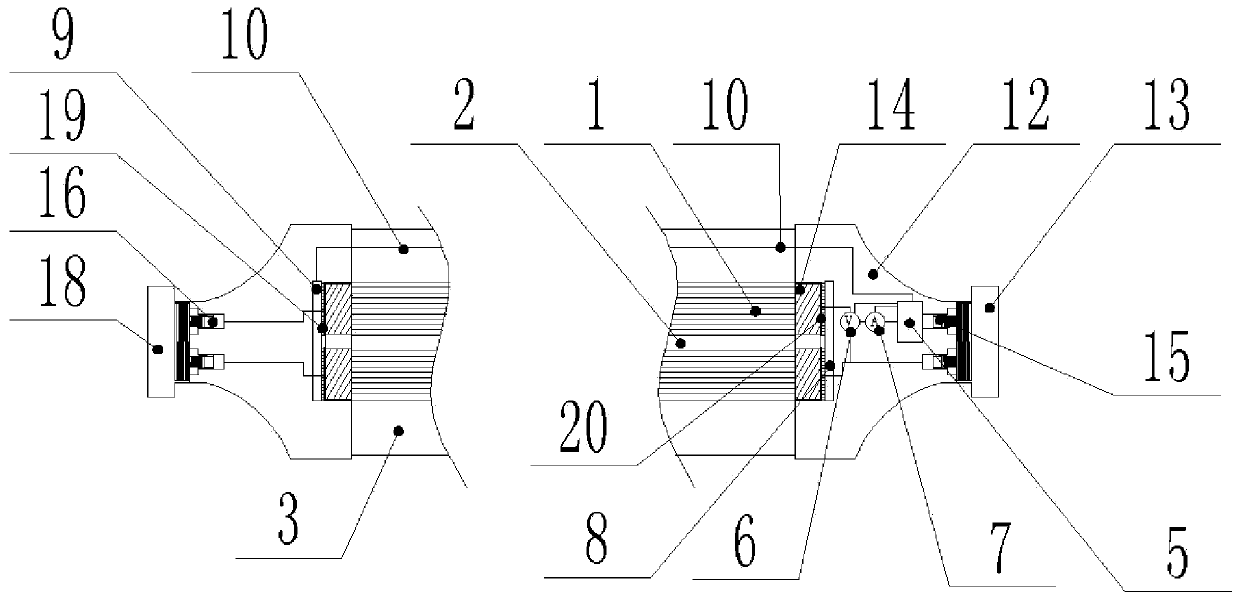

[0063] Embodiment 1: The interface self-detection high-strength ultra-thin anti-bending tape wire and cable of this embodiment includes a conductor layer 1, a high-strength insulating sheath 2, an adhesive layer and an interface; the conductor layer 1 includes a braided calendered conductor and an optical fiber; the braided The calendered conductor is a braided tape formed by calendering after weaving metal wires with a diameter of less than 0.2mm. The thickness of the flattened braided calendered conductor does not exceed 0.6mm; the optical fibers are parallel and evenly distributed around the braided calendered conductor; high-strength insulation At least one signal line 10 is arranged in the sheath 2 .

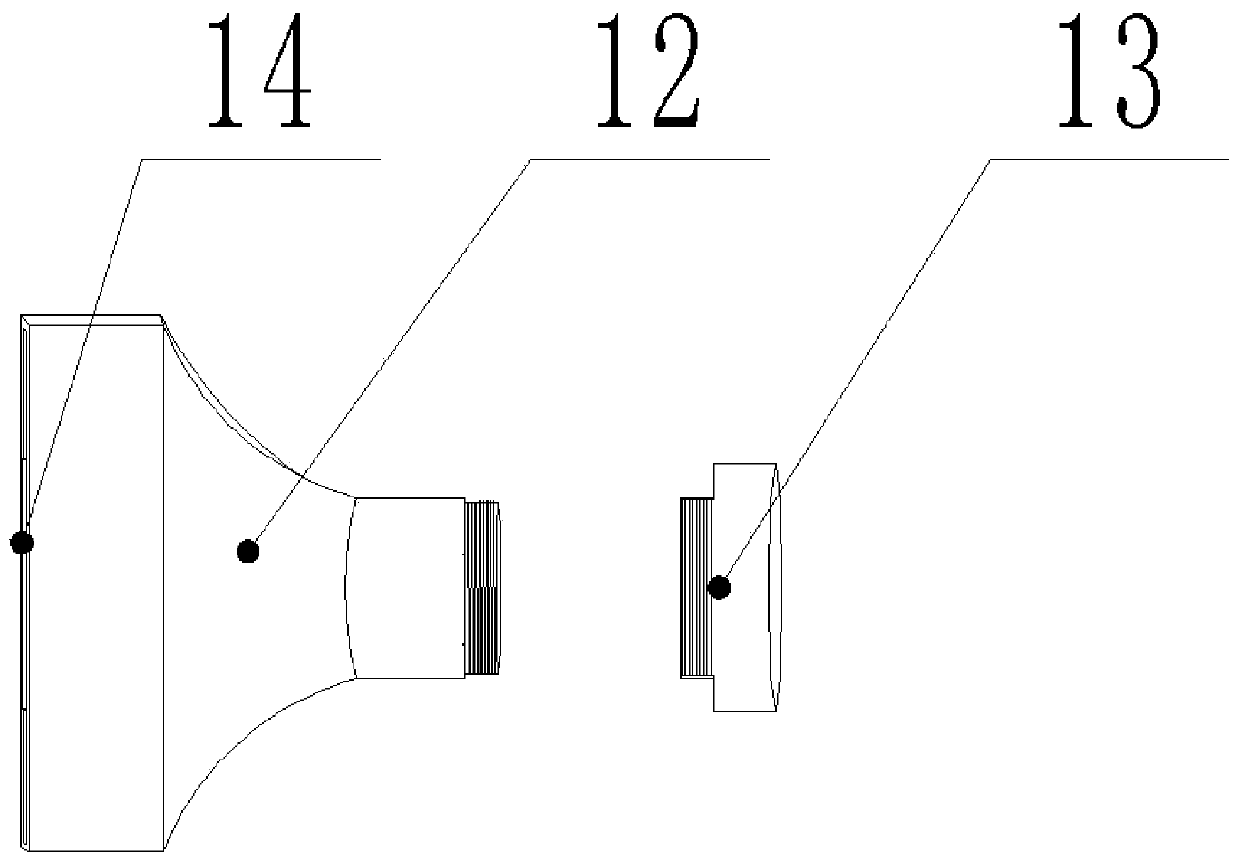

[0064] The interface includes an input interface 12 and an output interface 18, and the size and shape of the input interface 12 and the output interface 18 are the same. The input interface 12 includes a matching first housing with buckles and a first flat conductor connect...

Embodiment 2

[0078] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is:

[0079] There are multiple signal wires 10, and the signal wires 10 are evenly distributed in the high-strength insulating sheath 2 around the optical fiber. The weight ratio of copper, titanium and nickel in the metal wire is 85%:5%:1%. Screws are arranged in the first round wire connection port 15 and the second round wire connection port 16, and the connected round wires are fixed by the screws. The shapes of the input interface 12 and the output interface 18 have no specific requirements. One end of the input interface 12 is provided with a first round wire connection port 15 connected to the circuit, and the other end is provided with a first flat conductor connection port 14, and a switch module 5 and a switch module are connected in series in the middle. The current safety monitoring module 7 is connected in parallel with the voltage safety monitoring module 6. The current s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com