A new device for making anti-crack socks and its process for making anti-crack socks

A production device and anti-crack technology, applied in socks, pantyhose, coatings, etc., can solve the problems of low production efficiency, low degree of automation, inability to meet the needs of mass production and large-scale production, and achieve high production efficiency and automation. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

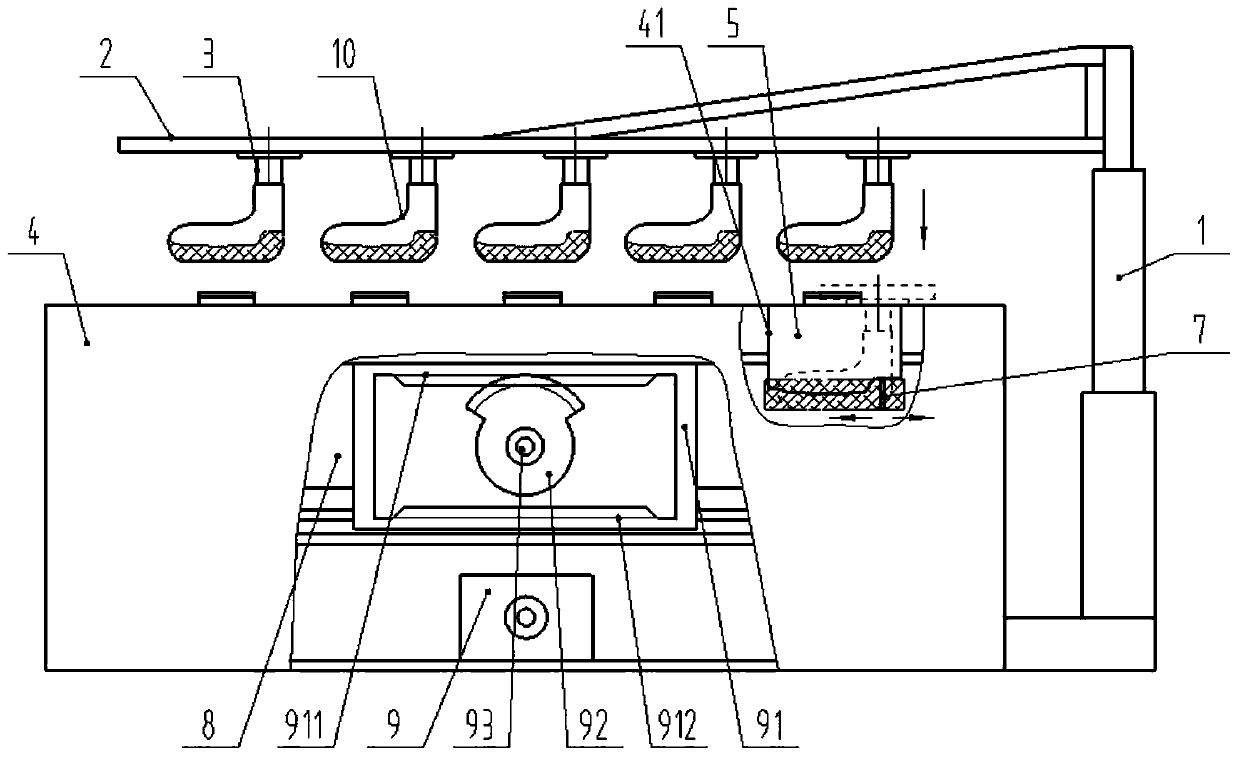

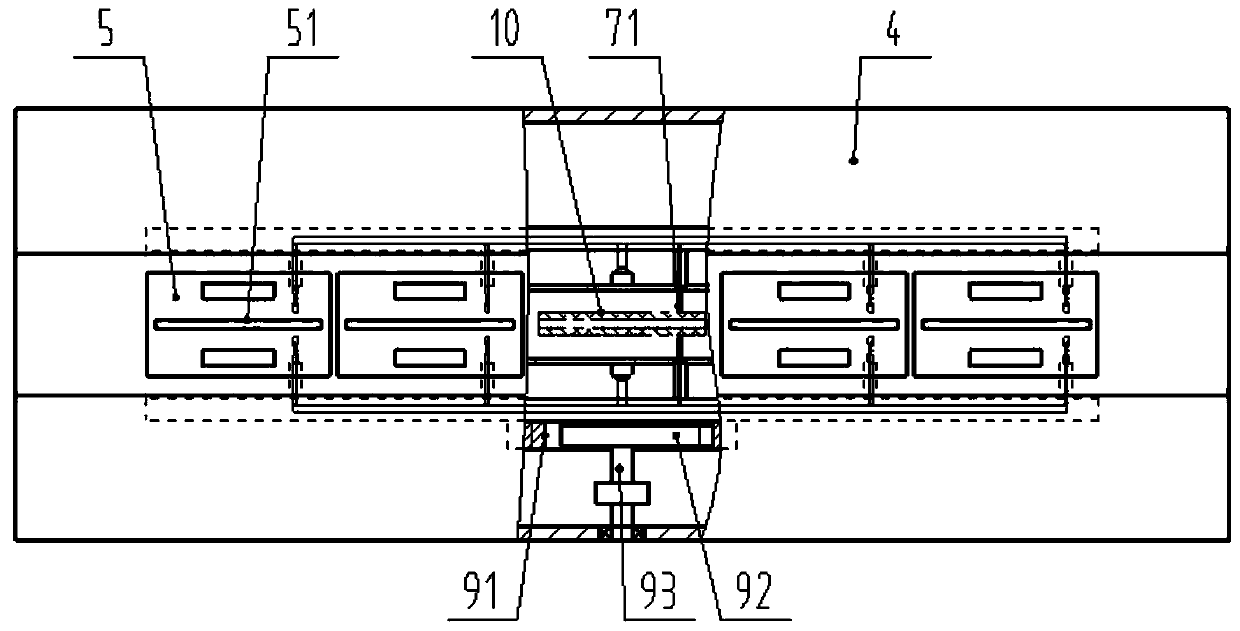

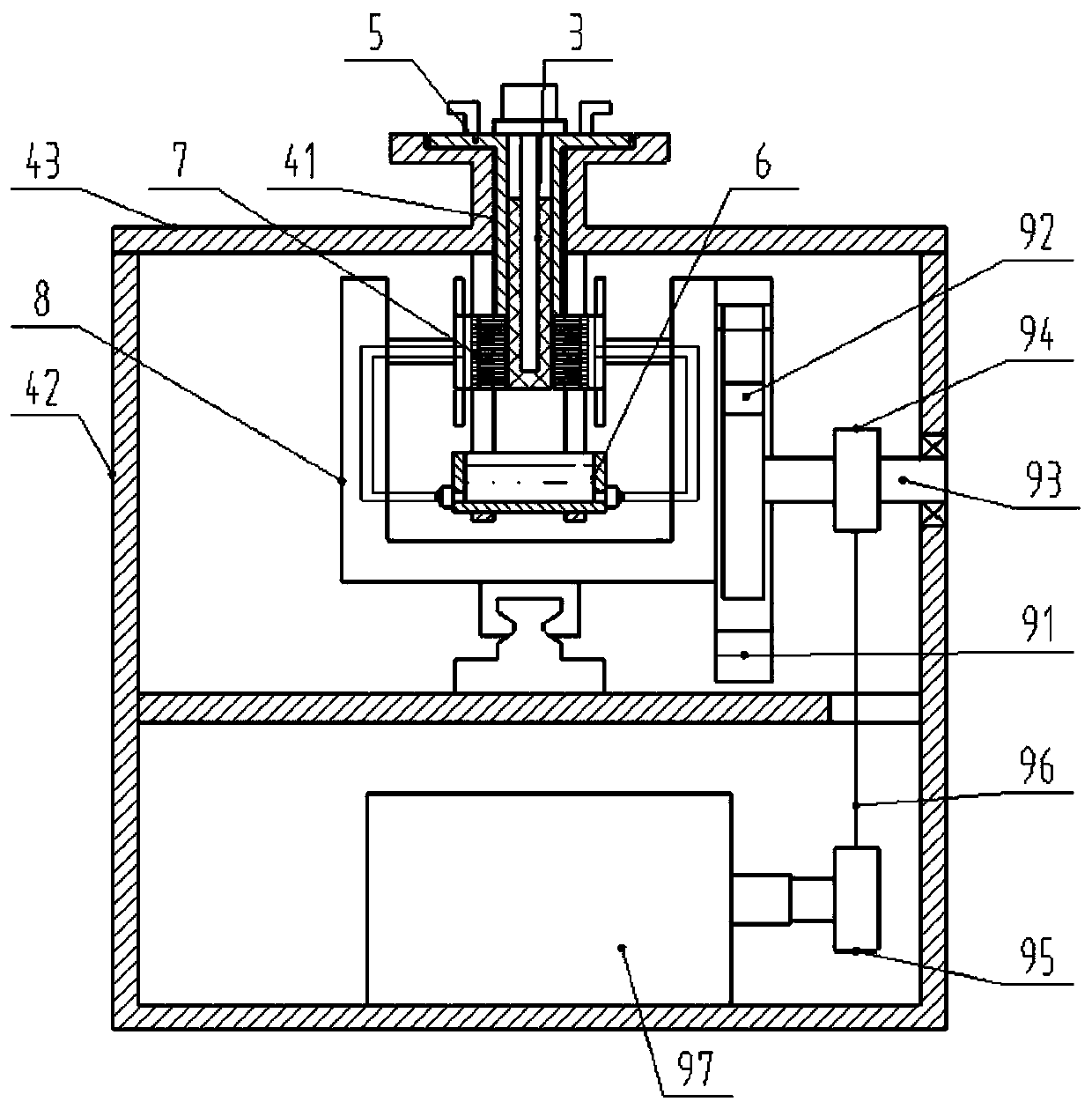

[0037] Such as Figure 1 to Figure 6As shown, a new type of anti-cracking sock production device in this embodiment includes a lifting rod 1, a support 2 arranged at the lifting end of the lifting rod, a plurality of sock body templates 3 arranged on the support and arranged at intervals along the horizontal part of the support and the coating assembly disposed below the horizontal portion of the support, combined with figure 1 As shown, the bracket has a vertical part connected with the lifting end of the lifting rod and a horizontal part that is horizontally used for hanging or hanging the sock body formwork. A mature lifting structure, which is not limited or repeated here; the sock body template is the template for nesting the sock body 10, preferably the sock body template is a flat plate whose shape matches the sock bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com