Construction Method of Secondary Lining of Steel-Concrete Composite Pipe Joint Jacking Channel

A construction method and technology of composite pipes, which are applied in tunnel lining, tunnel, wellbore lining and other directions, can solve the problems of easy cracking at joints of steel pipes and differences in lateral stress, so as to reduce lateral stress, reduce the influence of thermal expansion, and reduce the possibility of water seepage. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be more clearly and completely described below by means of embodiments and in conjunction with the accompanying drawings.

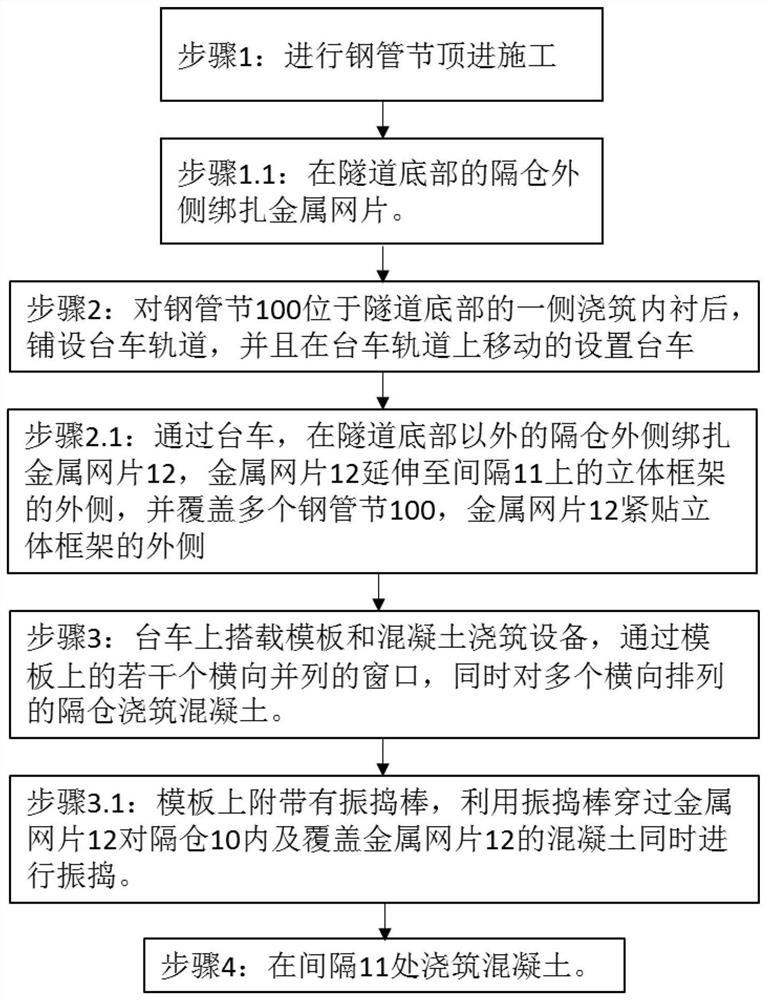

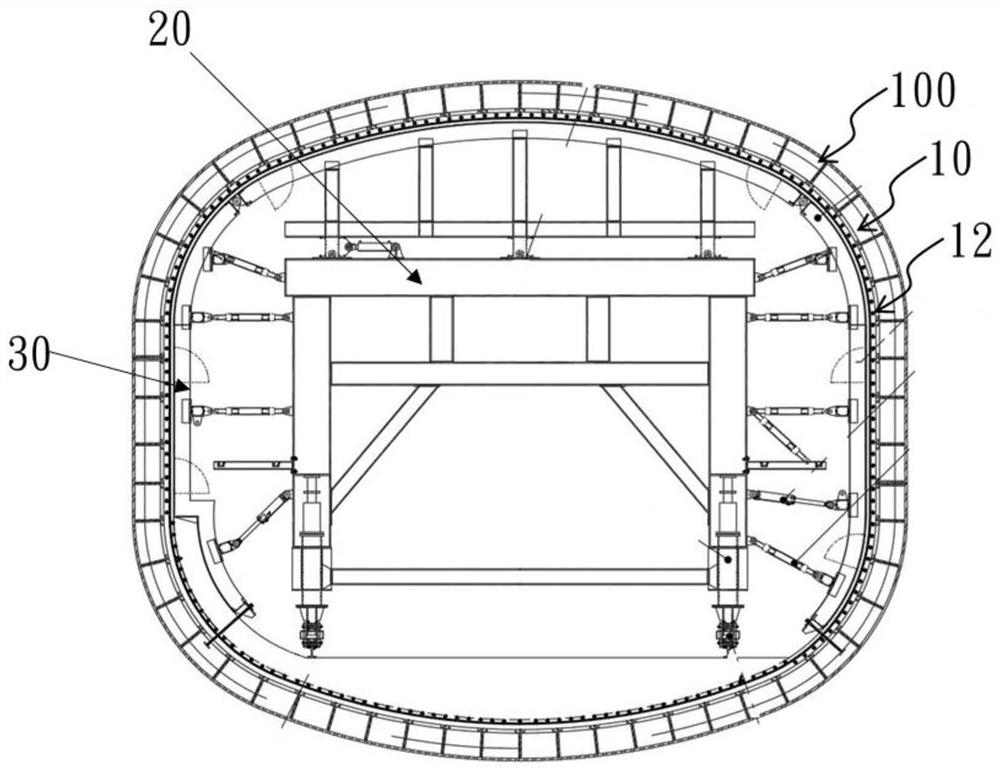

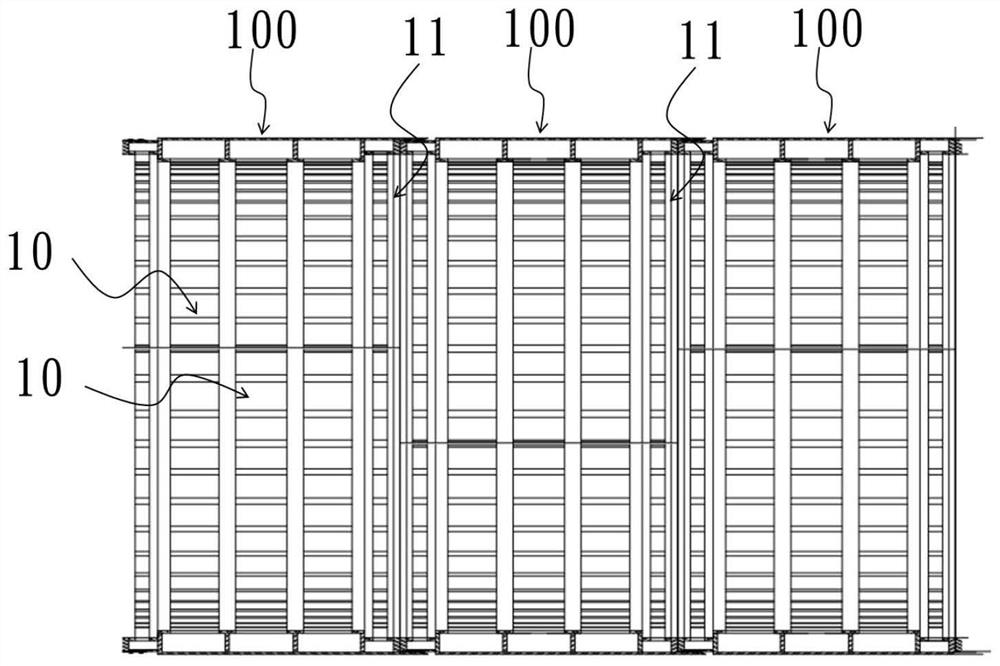

[0025] figure 1 It is a flow chart of the construction method of the secondary lining of the steel-concrete composite pipe joint pipe jacking channel of the present embodiment, figure 2 It is a schematic structural diagram of the channel of this embodiment, image 3 It is a schematic diagram of the structure of the steel pipe joint in this embodiment, Figure 4 It is a structural schematic diagram of steel pipe sections and compartments bound with metal mesh sheets in this embodiment. Such as Figure 1~4 As shown, the construction method for the secondary lining of the steel-concrete composite pipe joint pipe jacking channel involved in this embodiment includes the following steps:

[0026] Step 1, carry out steel pipe section jacking construction.

[0027] refer to figure 2 , 3 , image 3 There are three steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com