Thermostat control device and thermostat control method

A control device and thermostat technology, applied in the control of coolant flow, machine/engine, engine components, etc., can solve the problems of vehicle fuel economy deterioration, damage to the engine, and shorten the service life of the engine to achieve small fluctuations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

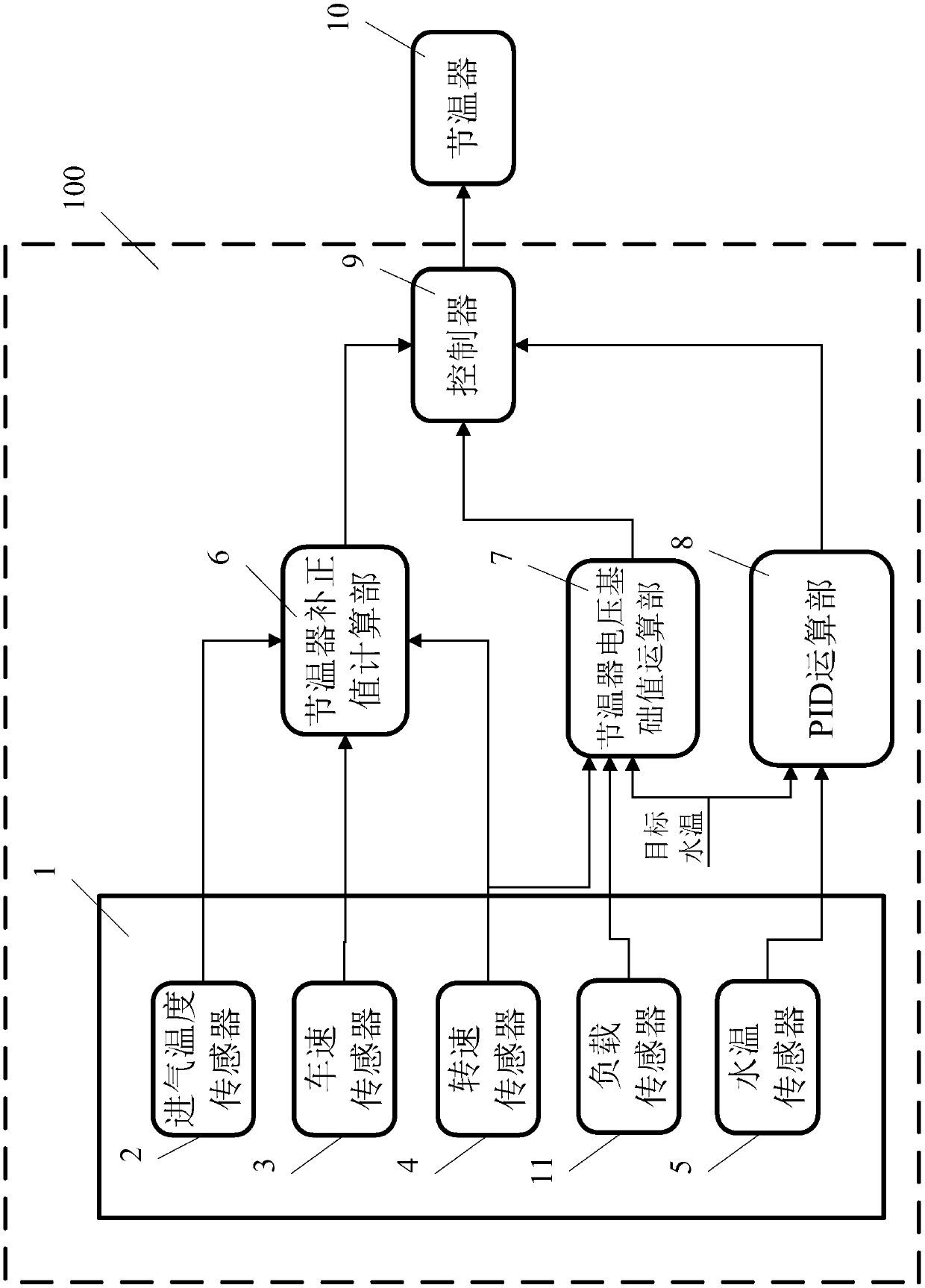

[0020] figure 1 It is a block diagram showing the thermostat control device 100 according to Embodiment 1 of the present invention. The thermostat control device 100 will be specifically described below.

[0021] The thermostat control device 100 outputs a thermostat control voltage to the thermostat 10 so that the thermostat 10 can adjust the temperature of the coolant of the engine appropriately. The thermostat control device 100 includes: a sensor group 1 , a thermostat correction value calculation unit 6 , a thermostat voltage base value calculation unit 7 , a PID calculation unit 8 , and a controller 9 .

[0022] The sensor group 1 includes a plurality of sensors: an intake air temperature sensor 2 , a vehicle speed sensor 3 , a rotational speed sensor 4 , a water temperature sensor 5 and a load sensor 11 . The intake air temperature sensor 2 detects the intake air temperature of the engine, the vehicle speed sensor 3 detects the speed of the vehicle, the rotational sp...

Embodiment approach 2

[0057] Figure 6 A block diagram showing a thermostat control device 100' according to Embodiment 2, Figure 7 The control method of the thermostat control device according to Embodiment 2 is shown, and the same blocks and steps as those in Embodiment 1 are denoted by the same reference numerals. Only the parts of Embodiment 2 that are different from Embodiment 1 will be described below.

[0058] Such as Figure 6 As shown, the thermostat control device 100' further includes a battery voltage correction value calculation unit 11. The battery voltage correction value calculation unit 11 has a battery voltage correction table T2 with the battery voltage VB as a variable, and refers to the battery voltage correction table T2 based on the battery voltage VB. The table T2 outputs the battery voltage correction value Cvb to the controller 9 . Therefore, when calculating the thermostat control voltage Vctl, the controller can take the battery voltage VB of the car into considerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com