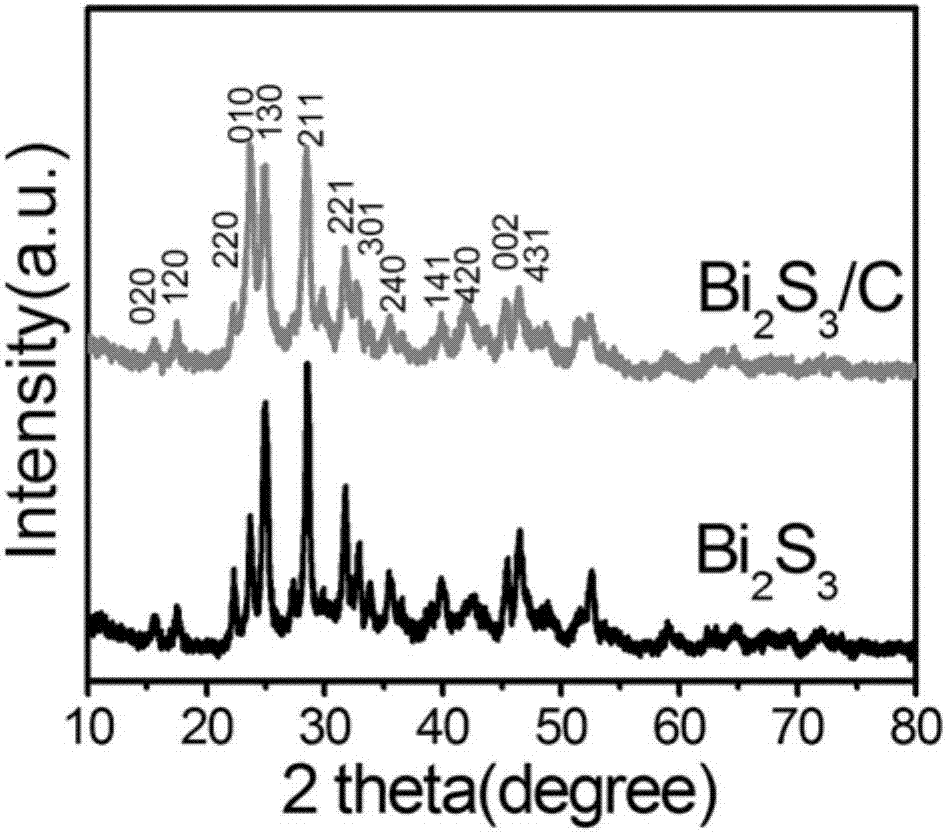

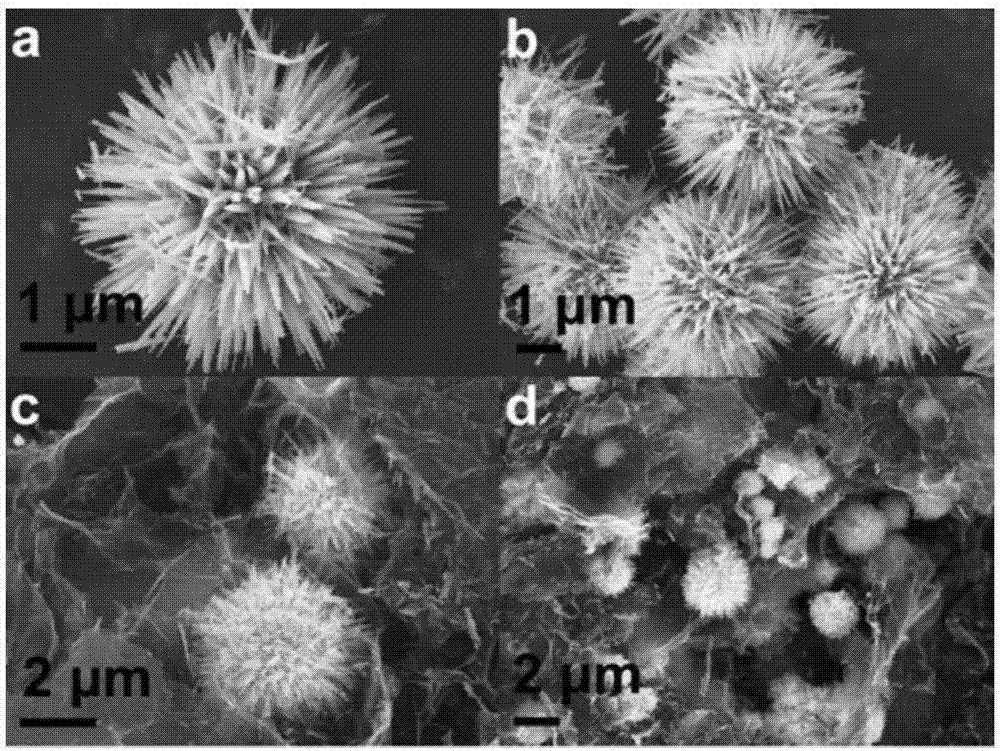

Sea-urchin-shaped bismuth sulfide/macropore graphene composite material, preparation method and application thereof

A composite material and graphene technology, applied in the direction of electrochemical generators, electrical components, battery electrodes, etc., can solve the problems of large volume effect, restricting the application of lithium-ion battery anode materials, poor cycle stability, etc., and achieve simple equipment requirements, Low preparation cost and the effect of relieving volume expansion pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Prepare 0.2 mol / L bismuth nitrate aqueous solution:

[0030] Weigh 9.7020 g Bi(NO 3 ) 3 ·5H 2 O was placed in a small beaker, dissolved in deionized water, drained into a 100 mL volumetric flask with a glass rod, and then made to volume with deionized water to obtain a 0.2 mol / L bismuth nitrate aqueous solution.

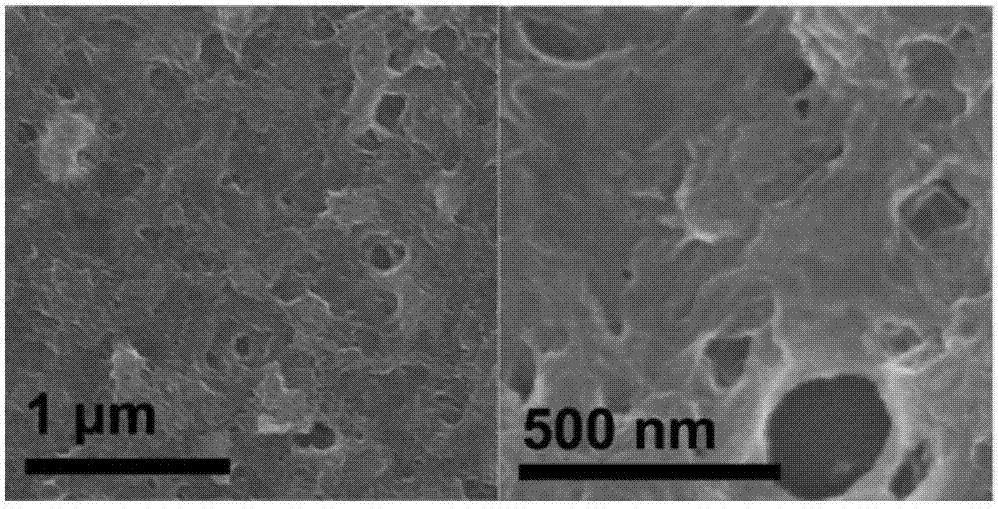

[0031] 2. Preparation of macroporous graphene

[0032] Weigh 60 mg of graphene oxide and make up 3 mg mL -1 Graphene oxide suspension, after ultrasonic treatment (ultrasonic treatment time 2 h, power 55 kHz), the suspension was transferred to the reactor lining made of polytetrafluoroethylene, and the lining was put into the steel In the reaction kettle of the prepared material and tighten the upper cover of the reaction kettle, then place the reaction kettle in a constant temperature blast drying oven and set the temperature to 180 o C, reacted for 12 h, the macroporous graphene prepared under the conditions of concentration, temperature and time had ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com