Mass concrete intelligent curing system and curing method

A large-volume concrete and curing system technology, applied in the direction of instruments, measuring devices, water supply devices, etc., can solve the problems of insufficient temperature control details, difficulty in moisturizing under the heat preservation quilt, and imperfect effects, so as to reduce manpower input, Reduce the labor multifunctional intensity of workers, reduce the effect of increase or decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

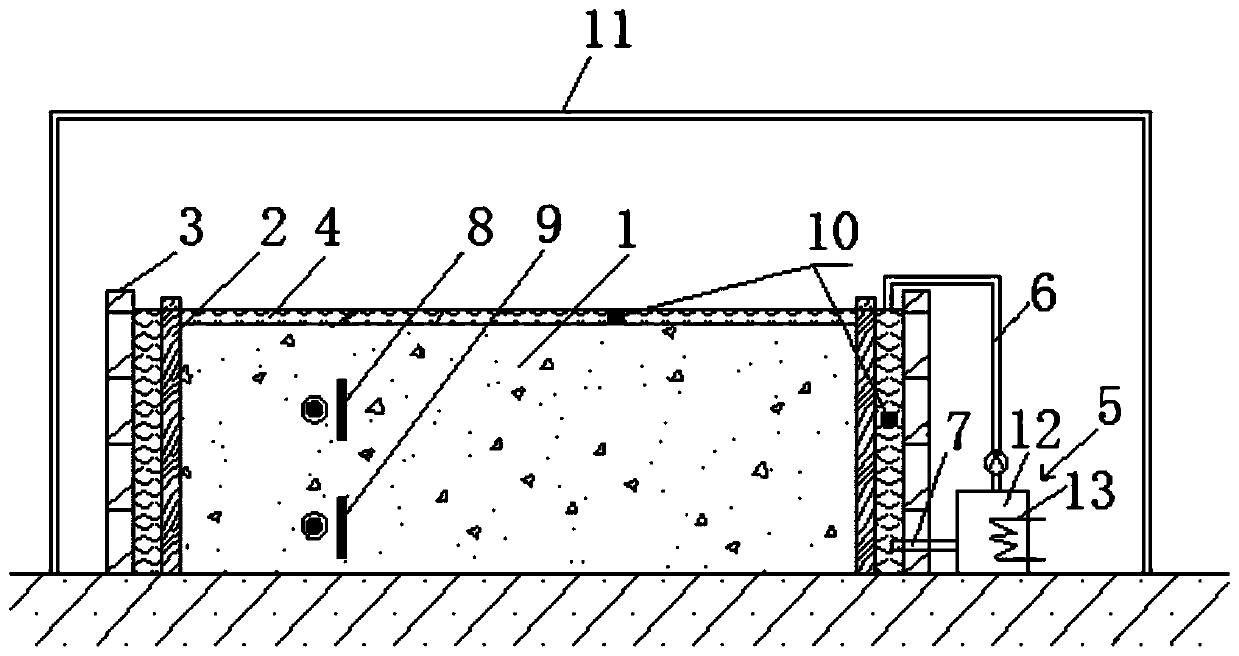

[0031] Such as figure 1 As shown, the large-volume concrete intelligent maintenance system of the present invention includes a permeable formwork 2, a temporary retaining wall 3, maintenance water 4, an automatic temperature control cycle device 5 for maintenance water, a temperature monitor 8, a stress monitor 9, a temperature sensor 10 and Conservation greenhouse 11.

[0032] The permeable formwork 2 is arranged on the periphery of the mass concrete 1 and is close to the side wall of the mass concrete, so as to facilitate moisture retention and heat conduction. The permeable template 2 is preferably a permeable cloth template, which has good abrasion resistance.

[0033] The temporary water retaining wall 3 is arranged on the periphery of the permeable formwork 2 and has a certain distance from the permeable formwork...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com