Automatic hole aligning method for aluminum template

An aluminum formwork, automatic technology, applied in the direction of geometric CAD, etc., can solve the problems that the aluminum formwork cannot be free from pre-assembly, the aluminum formwork cannot be automatically matched, and consumes human resources, etc., so as to achieve the realization of no pre-assembly, improve design efficiency, and reduce manpower The effect of resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

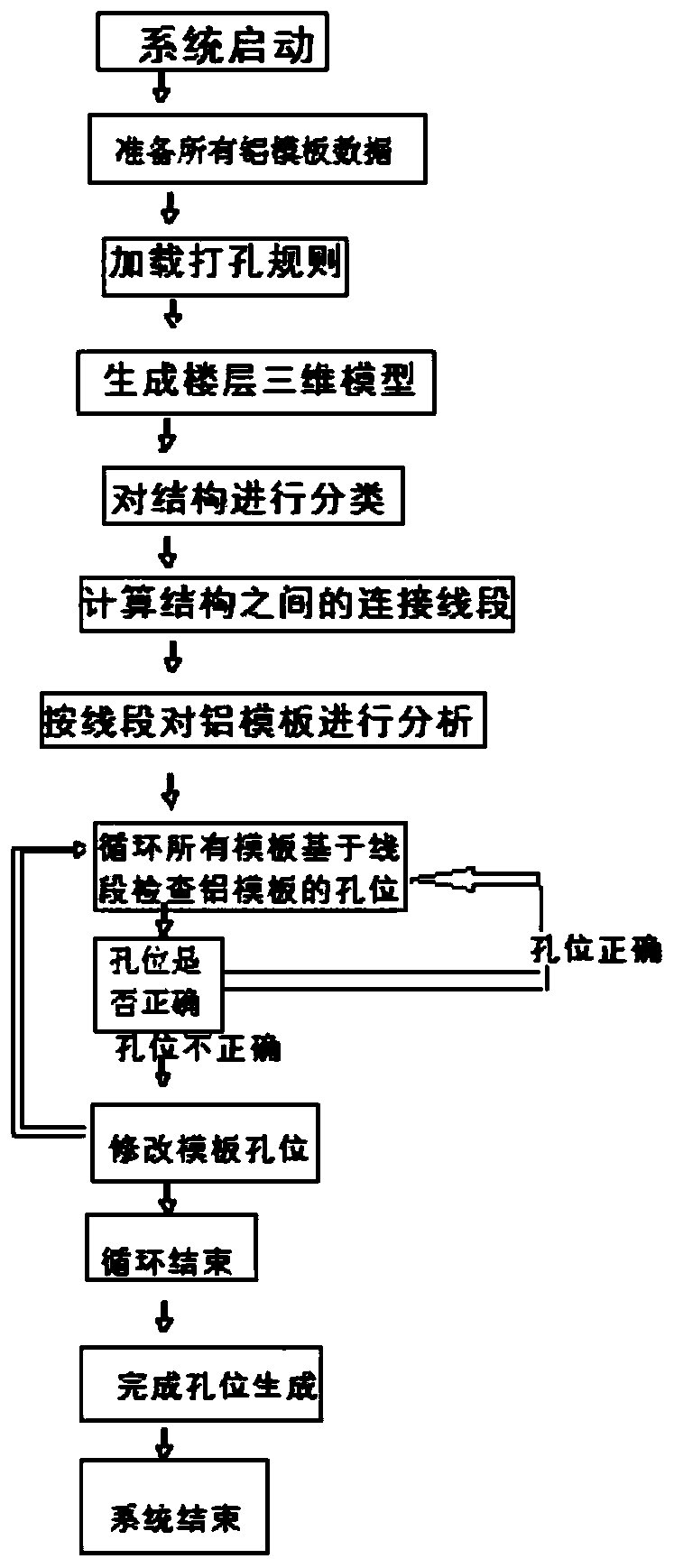

[0023] A method for automatically aligning holes in an aluminum formwork, the specific steps are as follows:

[0024] Step 1: Deepen according to the building structure drawings, intelligently identify the deepened drawings according to the layer and type, and obtain the floor structure data. This method is highly intelligent and does not require manual input one by one. Generate a 3D model of the floor based on the floor structure data Data, the 3D model data includes the length, width, height and inclination angle of the floor;

[0025] Step 2, classifying the three-dimensional model data, looping through all connecting line segments, calculating the hole positions of the connecting line segments according to the punching rules, and forming a hole position list of the connecting line segments;

[0026] Step 3, based on the spatial position of the template, calculate the template corresponding to the connecting line segment, determine whether the template is associated with t...

Embodiment 2

[0029] A method for automatically aligning holes in an aluminum formwork, the specific steps are as follows:

[0030] Step 1, intelligently identify the floor structure, obtain floor structure data, generate three-dimensional model data of the floor according to the floor structure data, and the three-dimensional model data includes the length, width, height and inclination angle of the floor;

[0031] Step 2: Classify the 3D model data according to walls, beams, slabs, bay windows and stairs, loop through all the connecting line segments, calculate the hole positions of the connecting line segments according to the drilling rules, and form the holes of the connecting line segments distributed in the form of a matrix array bit list;

[0032] Step 3. Based on the spatial position of the aluminum alloy formwork, calculate the aluminum alloy formwork corresponding to the connecting line segment, and judge whether the aluminum alloy formwork is related to the connecting line segme...

Embodiment 3

[0035] A method for automatically aligning holes in an aluminum formwork, the specific steps are as follows:

[0036] Step 1, deepening according to the building structure drawing, intelligently identifying the deepening drawing according to the layer and type, obtaining the floor structure data, and generating the three-dimensional model data of the floor according to the floor structure data;

[0037] Step 2: Classify the 3D model data according to walls, beams, slabs, bay windows and stairs, and loop through all the connecting line segments. The connecting line segments are the connecting line segments between structural parts based on the classified data. This connecting line segment is used for the aluminum alloy formwork For holes, calculate the hole position of the connecting line segment according to the punching rules, and form the hole position list of the connecting line segment;

[0038] Step 3: Based on the spatial position of the aluminum alloy template, calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com