Integrated process hazard analysis method and system and storage medium

A technique of hazard analysis and process, applied in the field of chemical production, to achieve the effect of avoiding deficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

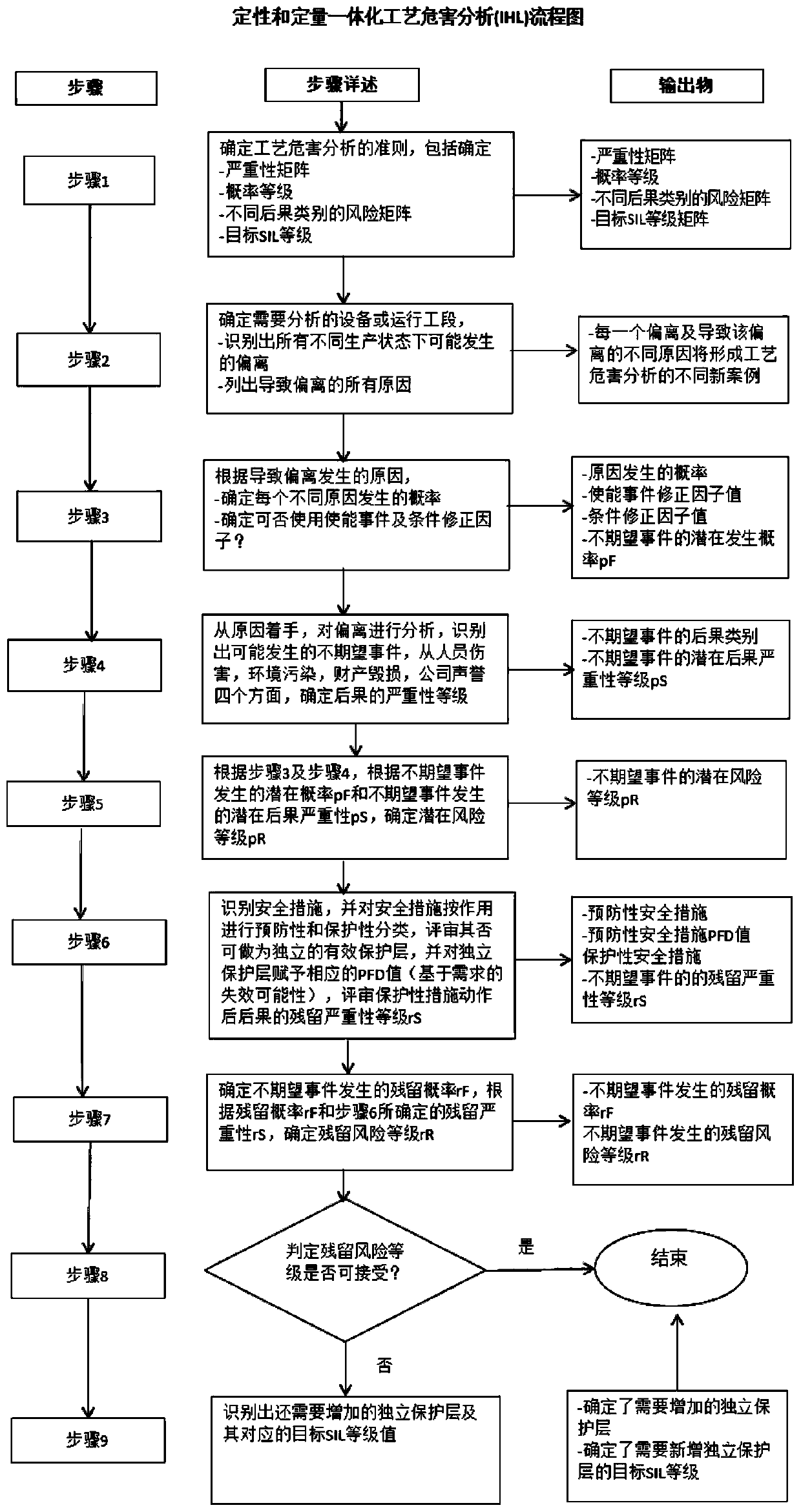

[0042] The present invention will be further described below in conjunction with the drawings. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

[0043] The inventor developed an integrated process hazard analysis method on the basis of many years of relevant work experience, starting from the design of new projects, for in-service installations, through each production state of production, and through the integrated half of the system. Quantitative process hazard analysis method, semi-quantitative analysis of all possible deviations in process production and all causes of deviations.

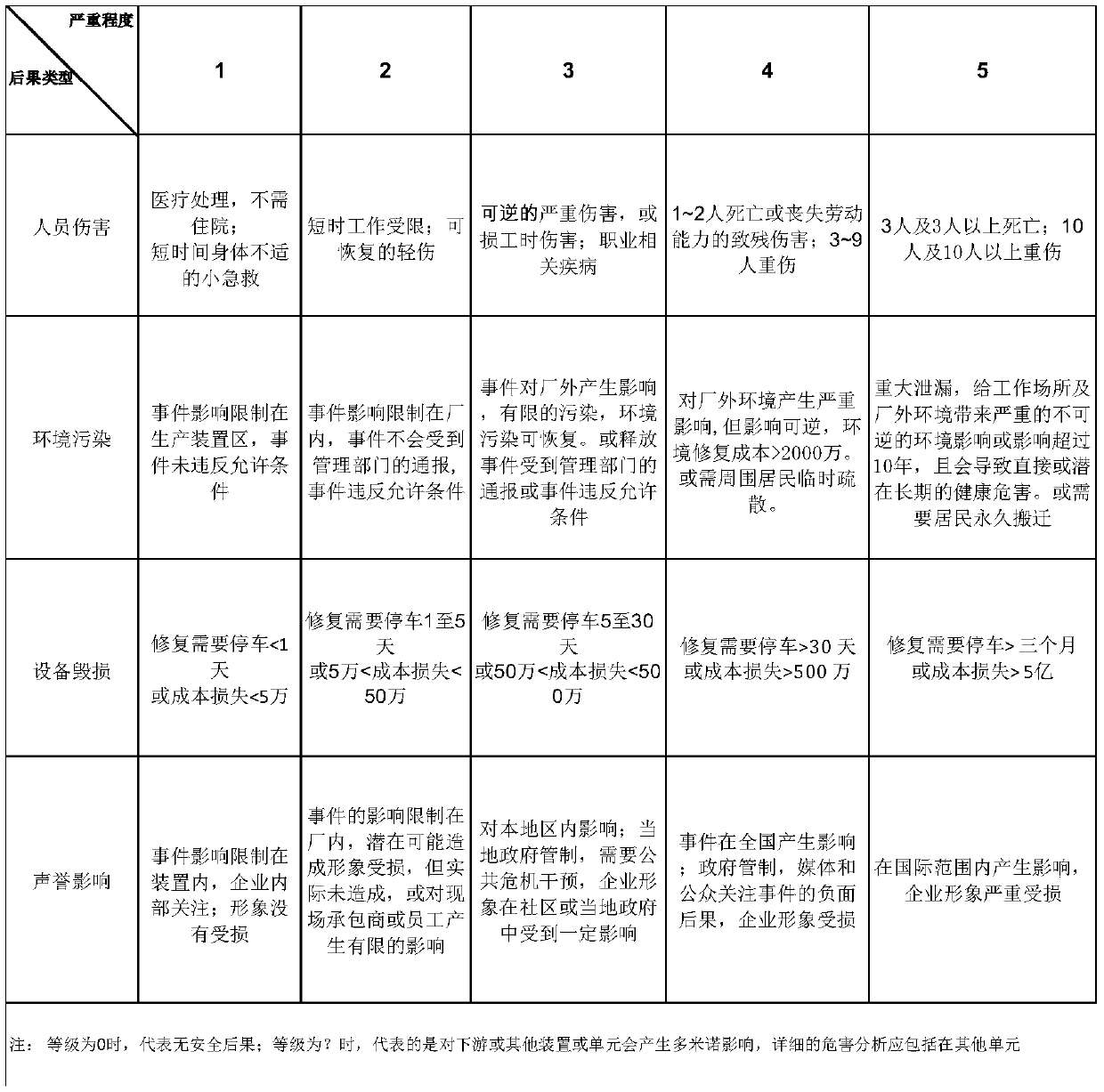

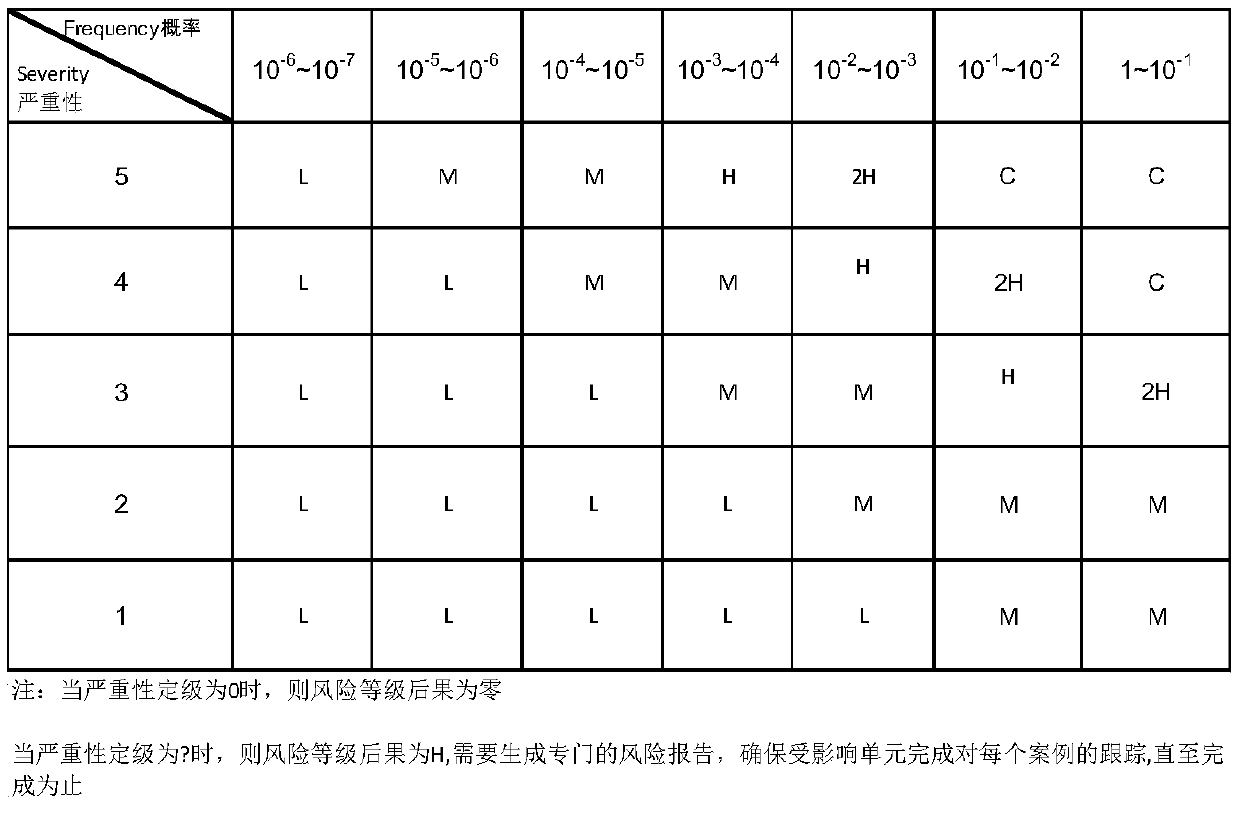

[0044] The present invention formulates different risk matrices for different harmful consequences. The dictionary function of the present invention enables the administrator to make customized modifications to the rules according to user requirements and ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com