Aircraft engine nacelle

An engine nacelle and engine technology, applied in the direction of machines/engines, engine manufacturing, aircraft parts, etc., can solve the problem of not being able to use large-sized nacelles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

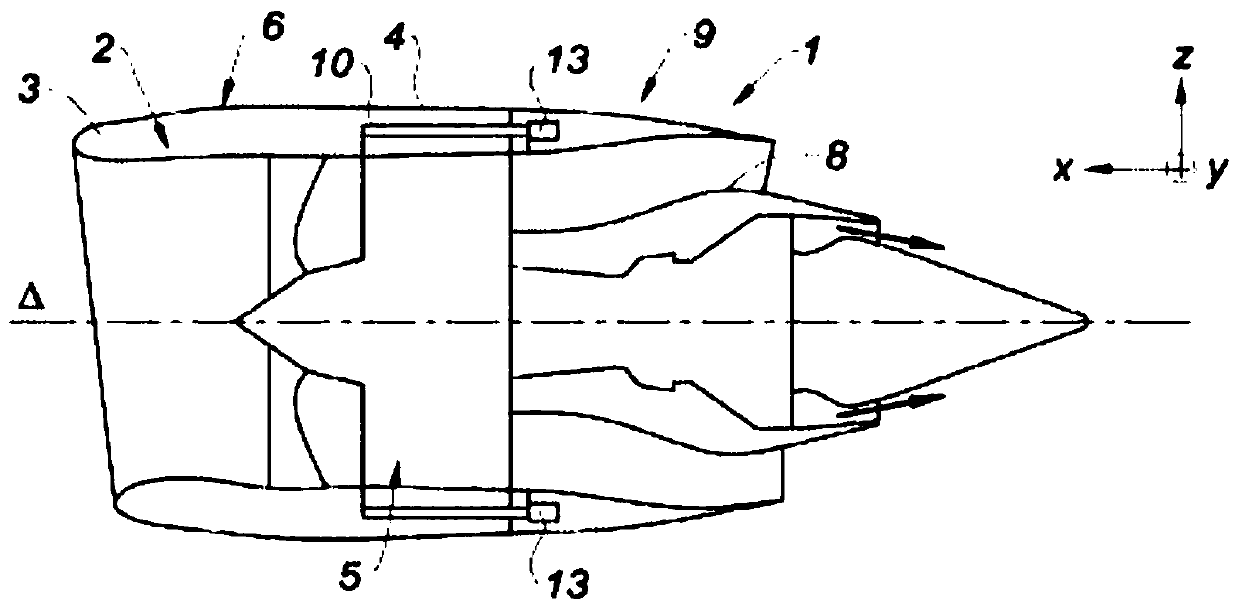

[0044] With reference to the figures, the nacelle 1 has, in a manner known per se, a substantially tubular shape along a longitudinal axis Δ. The nacelle 1 comprises an upstream section 2 with an air intake lip 3 , an intermediate section 4 surrounding a fan 5 of an engine, such as a bypass turbojet, and a downstream section.

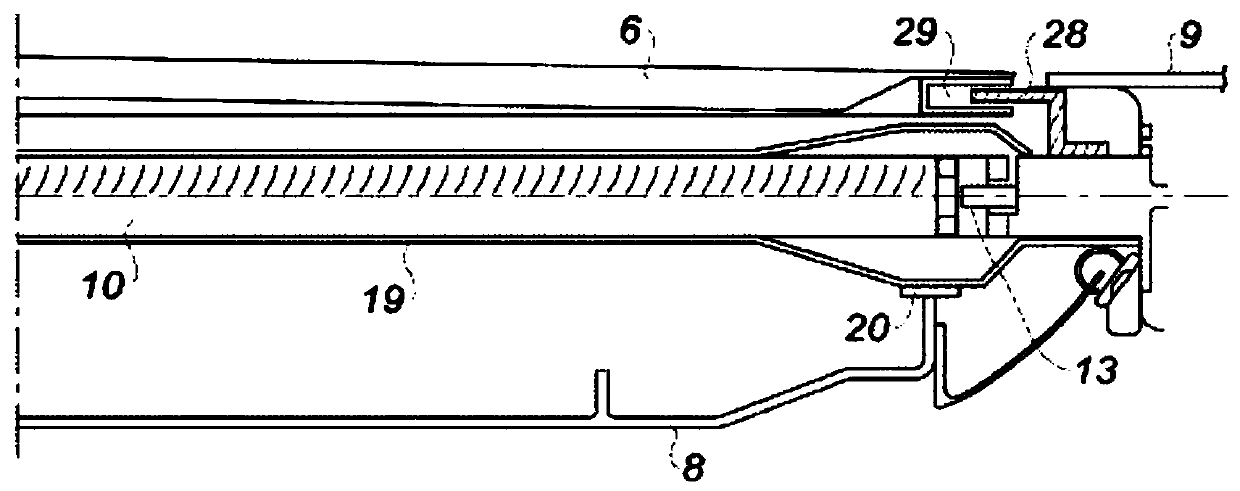

[0045] In particular, the middle section comprises a fan housing 8 surrounding the fan 5 and supporting a fan cowl 6 adapted to be swept externally by the air flow outside the nacelle 1 during flight.

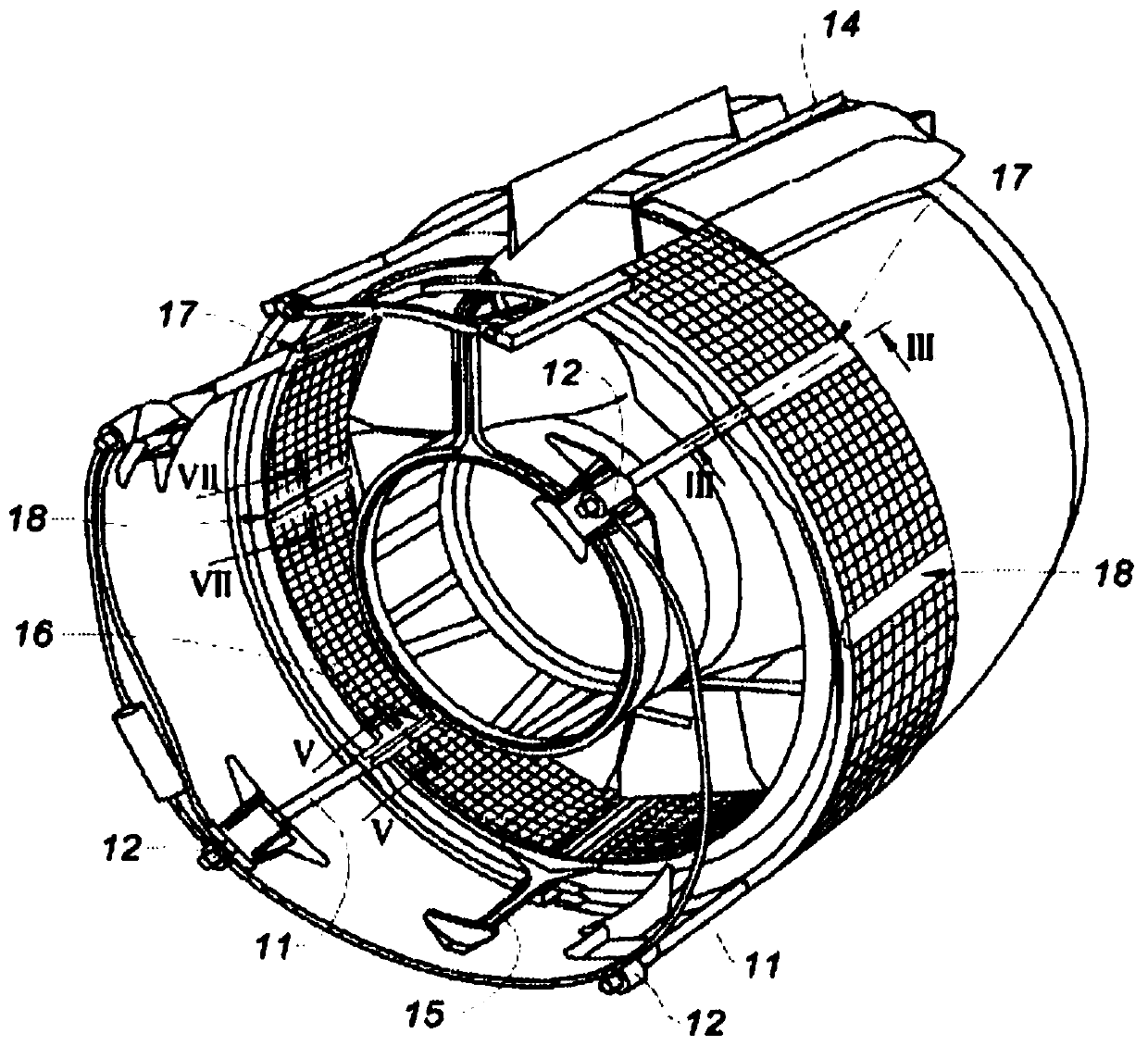

[0046] The downstream section comprises at least one movable cowl 9 comprising thrust reversal means. The movable cowl 9 is connected to the cascade 10 of the thrust reverser and is driven during thrust reversal by actuators, here four electromechanical cylinders, regularly distributed around the axis Δ and comprising fixed Rod 11 to end 13 of the downstream section, and motor 12 fastened to the middle section. During the displacement of the downstream...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com