Electrically insulated rolling bearings

A rolling bearing, electrical insulation technology, applied in the direction of bearings, shafts and bearings, bearing components, etc., can solve the problems of expensive, easy to break the ceramic oxide layer, etc., achieve the effect of high service life, wide range of electrical and mechanical characteristic values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

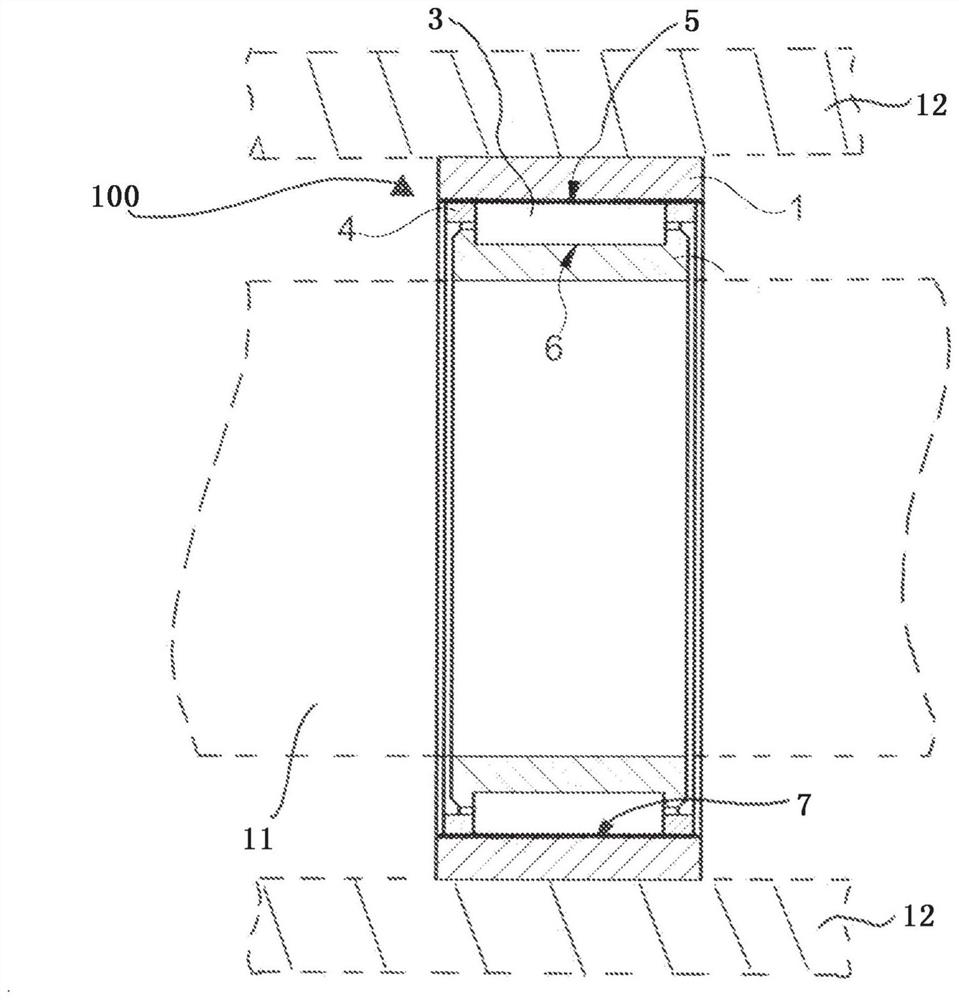

[0029] according to figure 1 , the electrically insulated rolling bearing 100 of the exemplary embodiment is configured as a radial bearing and essentially consists of an outer ring 1 , an inner ring 2 and rolling bodies 3 arranged therebetween, which are held in a cage 4 . Cage 4 is here made of a plastic material, while outer ring 1 , inner ring 2 and rolling elements 3 are made of tempered steel and are therefore electrically conductive depending on the material.

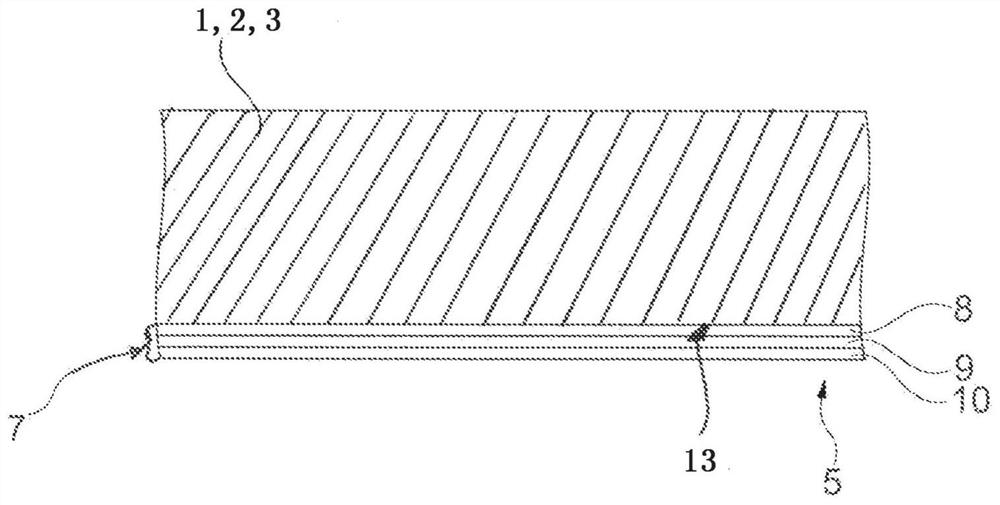

[0030] A first rolling element raceway surface 5 is formed on the inner peripheral side of the metal outer ring 1 . Correspondingly, a second rolling element raceway surface 6 is formed on the outer peripheral side of the inner ring 2 . The two rolling element raceways 5 and 6 are adapted to the shape of the rolling elements 3 , which are here designed as rollers.

[0031] In this embodiment, the insulating coating 7 described later (see also figure 2 ) is applied to the first rolling element raceway surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com