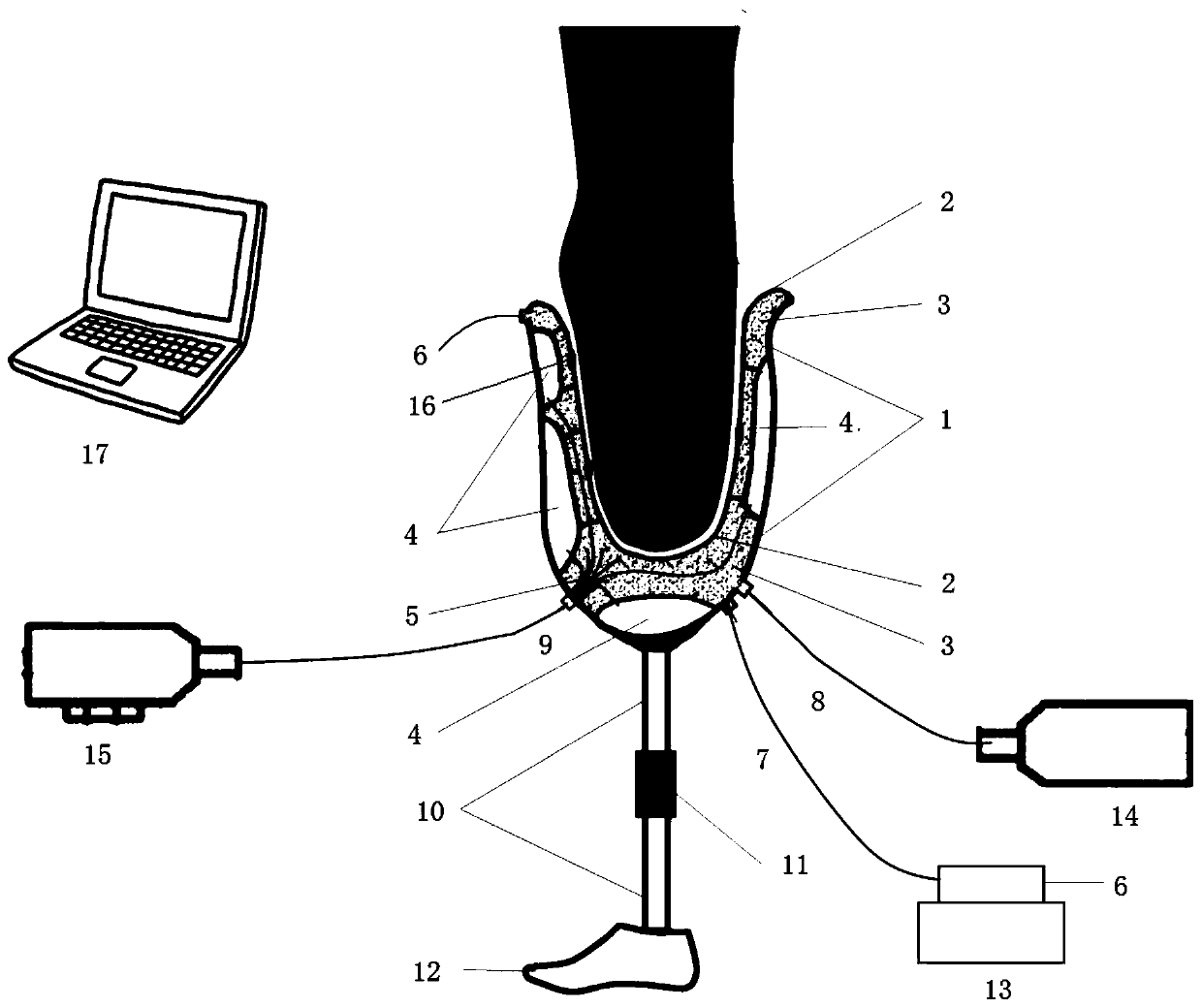

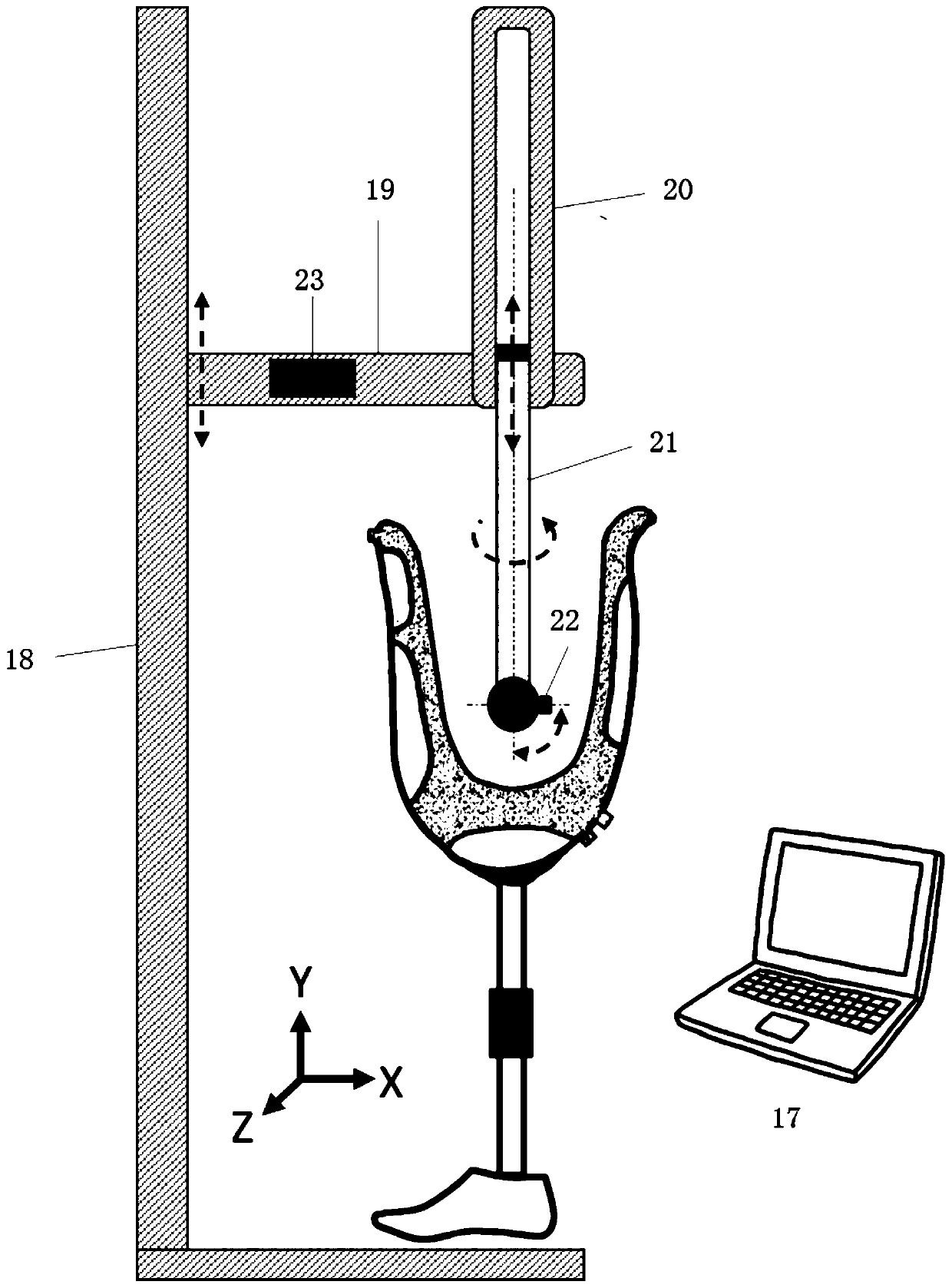

Method and system applied to loading modeling of crus prosthetic socket

A socket and calf technology, applied in prosthetics, medical science, etc., can solve the problems that the mechanical characteristics of the residual limbs are insufficient, cannot fully reflect the biomechanical performance bearing capacity of the residual limbs, and cannot provide comfortable support for patients, so as to improve Production efficiency, comfort and applicability, and the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the present invention, but not to limit the scope of the present invention.

[0030] The orientation or position relationship terms such as up, down, left, right, inside, outside, front end, rear end, head, and tail in this application document are established based on the orientation or position relationship shown in the drawings. If the drawings are different, the corresponding positional relationship may also change accordingly, so this should not be understood as limiting the scope of protection.

[0031] In the present invention, the terms "installation", "connection", "connection", "connection", "fixation" and so on should be understood in a broad sense, for example, it can be a fixed connection, a detachable connection, or an integrated Connection c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com