Cement grinding mill discharging grid plate

A material grate and grate plate technology, which is applied in the field of cement production equipment, can solve the problems of easy blockage of the discharge grate plate, difficult discharge, and poor anti-clogging ability, so as to avoid clogging of the grate joints, improve the discharge effect, and prevent clogging. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

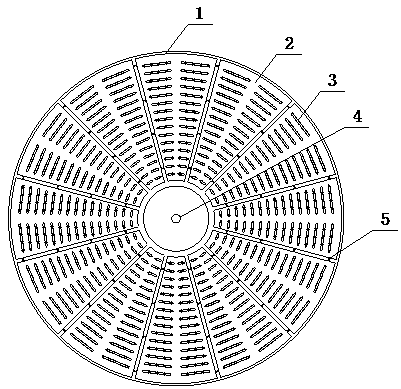

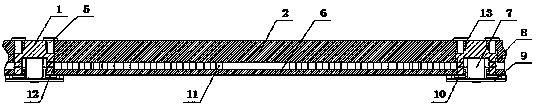

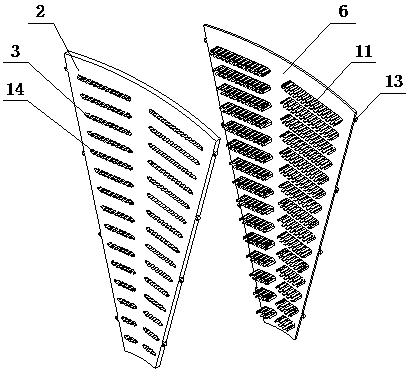

[0017] A cement mill discharge grate plate of the present invention is realized in this way: a cement mill discharge grate plate of the present invention is composed of a support frame (1), a main grate plate (2), a grate seam (3), a fixing screw hole (4 ), lock nut (5), auxiliary grate plate (6), servo motor (7), sliding column (8), wheel disc (9), pressure cap (10), auxiliary insert plate (11), return spring (12), fixed ear (13), slot (14), main board (15), cam (16) and connection sleeve (17), and the support frame (1) consists of a large ring and a small ring It is composed of connecting rods, the large ring and the small ring are concentric, a sliding column (8) is placed at the bottom of the connecting rod, and at least three main grate plates (2) are placed on the support frame (1) at equal angles, The main grate plate (2) is located between two adjacent connecting rods, the main grate plate (2) is a fan-shaped plate, and the two sides of the main grate plate (2) are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com