Medical instrument cleaning and drying device

A technology of drying device and medical equipment, applied in drying, drying machine, heating device and other directions, can solve the problems of waste of manpower and material resources, inconvenient use, poor cleaning efficiency, etc., and achieve easy access and improve drying. Efficiency, the effect of improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

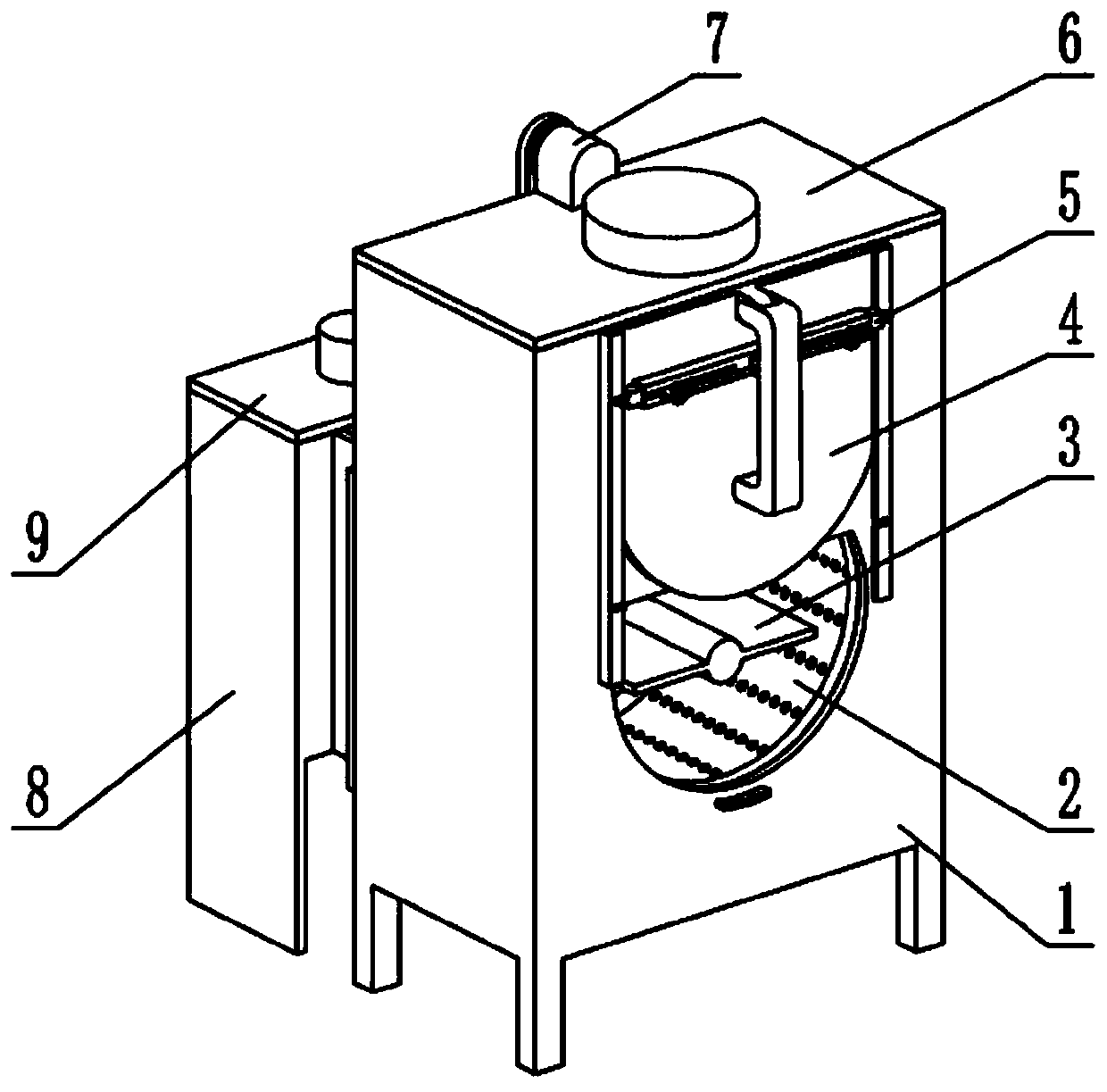

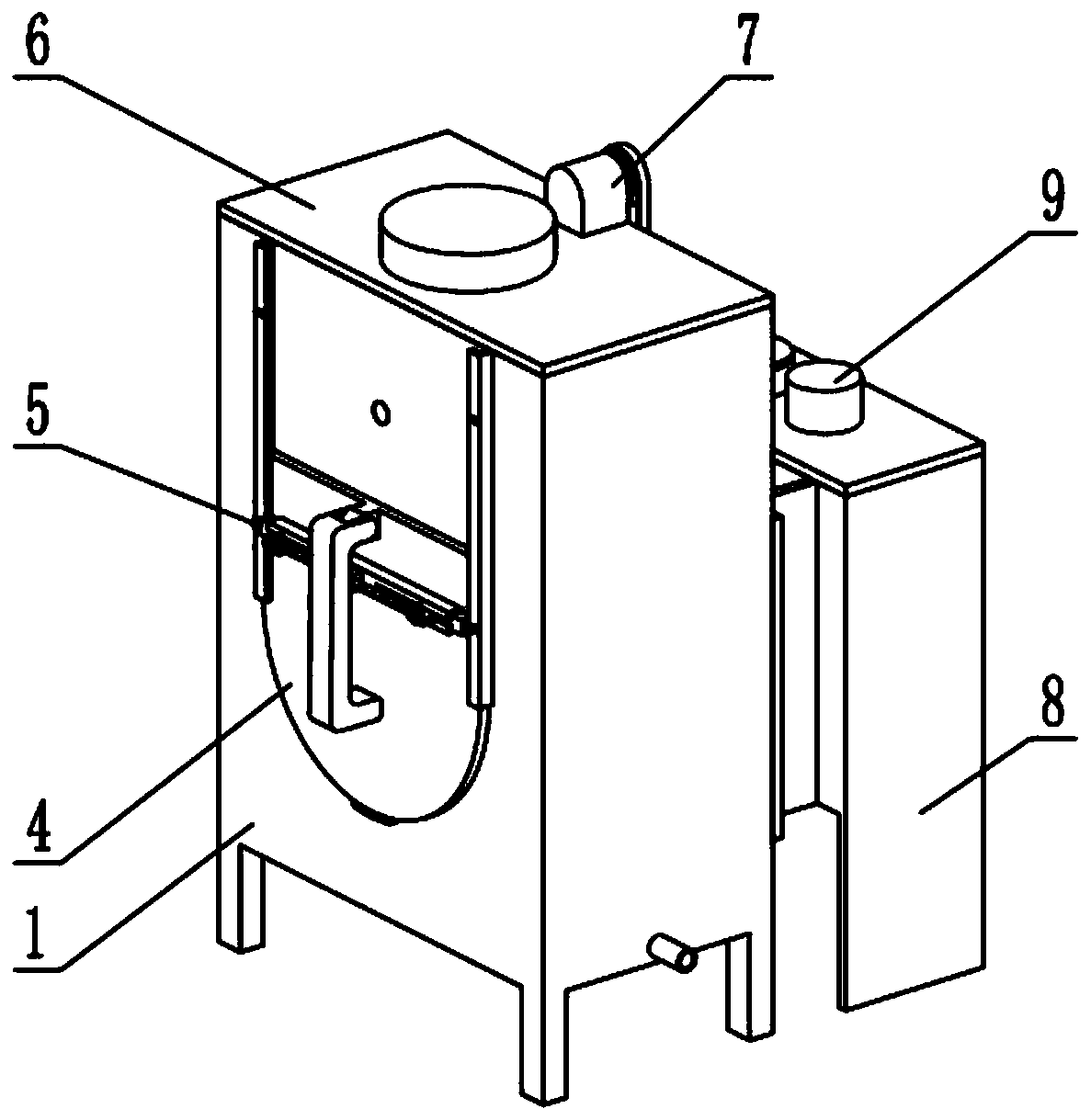

[0032] Such as Figure 1-13 As shown, a medical device cleaning and drying device includes a cleaning outer frame 1, a cleaning drum 2, an agitating mechanism 3, a lifting door mechanism 4, a door panel locking mechanism 5, a drying device 6, a power transmission mechanism 7, and a cleaning liquid containing mechanism 8 and a cleaning liquid stirring mechanism 9, the cleaning drum 2 is rotatably connected in the cleaning outer frame 1, the agitating mechanism 3 is rotatably connected in the cleaning outer frame 1, the agitating mechanism 3 is located in the cleaning drum 2, and the agitating mechanism 3 is located in the cleaning drum 2. Lifting door mechanism 4 is slidably connected to the front end of cleaning outer frame 1, and described door panel locking mechanism 5 is connected on the lifting door mechanism 4, and both ends of door panel locking mechanism 5 are all slidably connected with cleaning outer frame 1, and described drying The device 6 is fixedly connected to t...

specific Embodiment approach 2

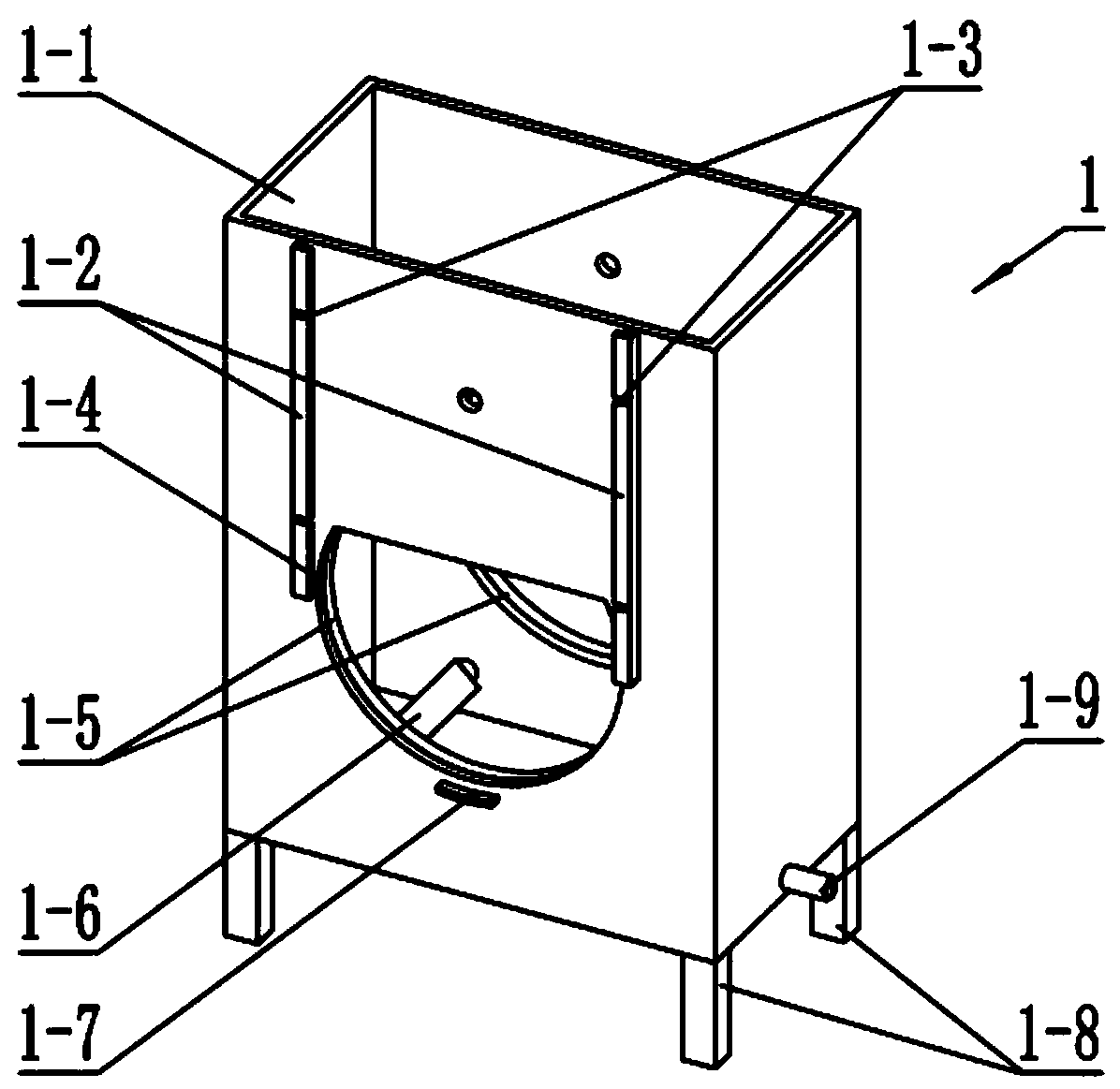

[0035] Such as Figure 1-13 As shown, the cleaning outer frame 1 includes an outer frame box 1-1, a slide rail plate 1-2, a locking groove 1-3, a door hole 1-4, a fixing ring 1-5, a spraying pipe 1-6, Limiting plate 1-7, supporting leg 1-8 and drain pipe 1-9, two slide rail plates 1-2 are provided, and both slide rail plates 1-2 are fixedly connected to the front end of outer frame box 1-1 , the upper and lower ends of the two slide rail plates 1-2 are provided with locking grooves 1-3, the front end of the outer frame box 1-1 is provided with door holes 1-4, and the door holes 1-4 are located on the two slide rail plates 1 Between -2, two fixed rings 1-5 are provided, and the two fixed rings 1-5 are respectively fixedly connected to the front and rear ends of the inner wall of the outer frame box 1-1, and four spray pipes 1-6 are provided, two of which are One spray pipe 1-6 is located in the two fixed rings 1-5, the other two spray pipes 1-6 are located in the lower part of...

specific Embodiment approach 3

[0038] Such as Figure 1-13 As shown, the cleaning drum 2 includes a toothed ring 2-1 and a trommel 2-2. There are two toothed rings 2-1, and the two toothed rings 2-1 are respectively fixedly connected to the front and rear of the trommel 2-2. At both ends, the two gear rings 2-1 are respectively rotatably connected to the two fixed rings 1-5 through bearings;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com