Cold and hot combined stamping forming device for aluminum alloy plate and stamping method thereof

An aluminum alloy plate, stamping forming technology, applied in the field of stamping, to achieve high mechanical properties, improve formability, and solve the effect of cracking and springback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0108] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and Embodiment 1. It should be understood that the specific implementation cases described here are only used to explain the present invention, and are not intended to limit the present invention.

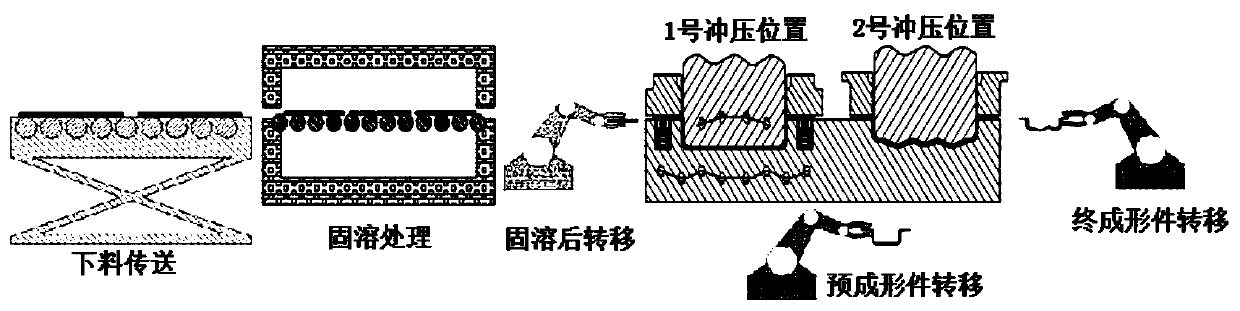

[0109] like Figure 1-Figure 5 As shown in Example 1, when the cold-heat composite stamping of aluminum alloy sheet is implemented, the stamping blank is a rectangular thin plate with a size of 500×300mm, the material is annealed 2024 aluminum alloy, and the thickness is 1.5mm. After stamping, the bottom surface is corrugated. Surface grooved parts.

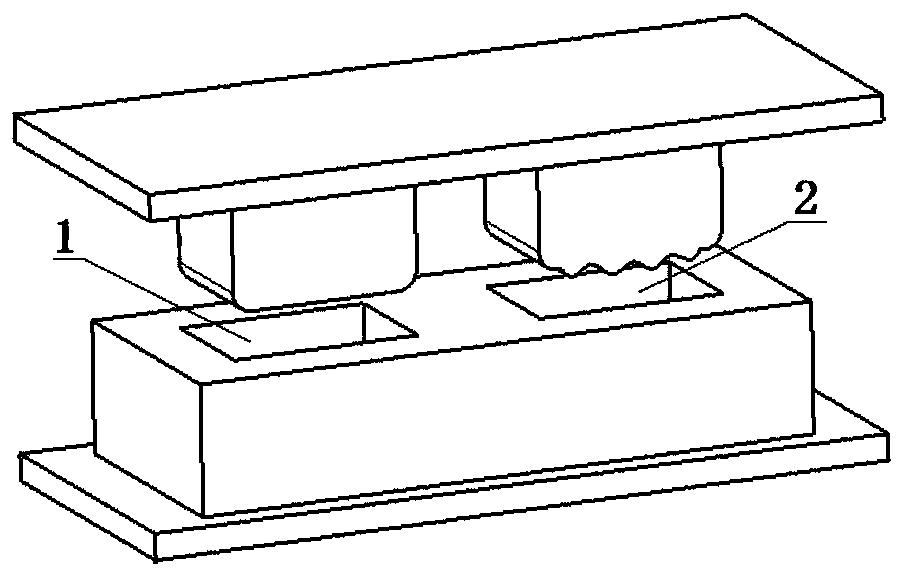

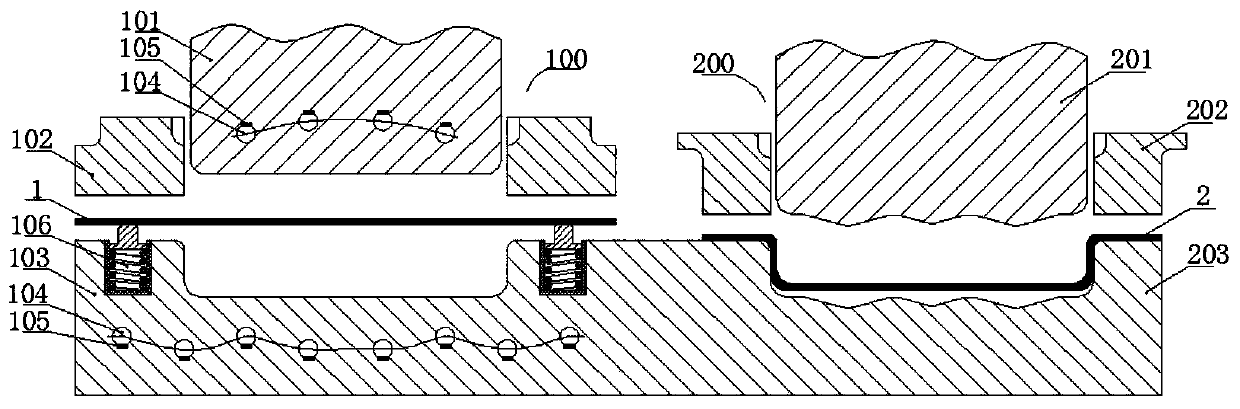

[0110] A cold and hot composite aluminum alloy sheet metal cold and hot composite stamping forming device, such as Figure 2-Figure 4 As shown, the device includes a pre-forming mechanism 100 at the No. 1 stamping position, and a...

Embodiment example 2

[0132] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and Embodiment 2. It should be understood that the specific implementation cases described here are only used to explain the present invention, and are not intended to limit the present invention.

[0133] like Figure 6-Figure 8 As shown in Example 2, when cold and hot composite stamping of aluminum alloy sheet is implemented, the stamping blank is a rectangular thin plate with a size of 500×700mm, and the material is annealed 2024 aluminum alloy with a thickness of 1.5mm. After stamping, the bottom surface is corrugated. Surface grooved parts. in, Figure 7 Yes Image 6 Partial left sectional view of Figure 8 Yes Image 6 Partial right sectional view of . use Figure 6-Figure 8 The device shown can achieve the purpose of producing multiple pieces at the sam...

Embodiment example 3

[0158] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and Example 3. It should be understood that the specific implementation cases described here are only used to explain the present invention, and are not intended to limit the present invention.

[0159] like Figure 9-Figure 11 As shown, in Example 3, when cold and hot composite stamping of aluminum alloy sheets is implemented, the width of the blank coil 303 is 300 mm. Solvent treatment. The material used is 7075 aluminum alloy in T6 state, with a thickness of 1.5mm. After punching, it is a groove-shaped part with a wave-shaped bottom surface.

[0160] A cold and hot composite aluminum alloy sheet metal cold and hot composite stamping forming device, such as Figure 9-Figure 11 As shown, the device includes a pre-forming mechanism 100 at the No. 1 stamping positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap