Packaging boarding box for automobile front windshield with high added-value

A front windshield, high value-added technology, applied in packaging, transportation and packaging, packaging of vulnerable items, etc. Empty container recovery loading rate, reduced shipping weight, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

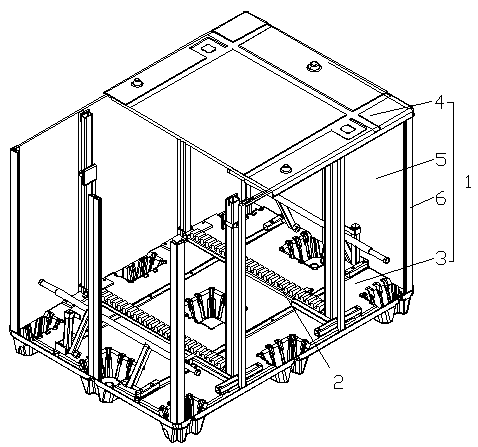

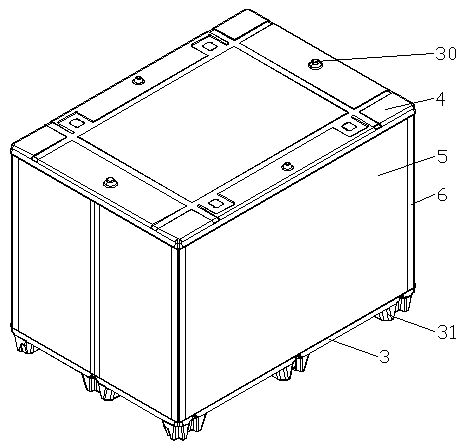

[0024] As shown in the attached picture, figure 1 The middle front side panel and the right side panel are hidden, and the box cover is partially hidden. The present invention includes a coaming box outer frame 1 and a coaming box inner lining 2 installed in the coaming box outer frame 1, and the coaming box outer frame 1 Including box bottom plate 3, box cover plate 4, a set of box coaming plate 5 and a set of ribbed plate 6, a set of box coaming plate 5 and a set of ribbed plate 6 are respectively plugged around the box bottom plate 3, and connected with the box bottom plate 3 Enclosing a box body with an open top, and the box cover plate 4 covers the top of the box body;

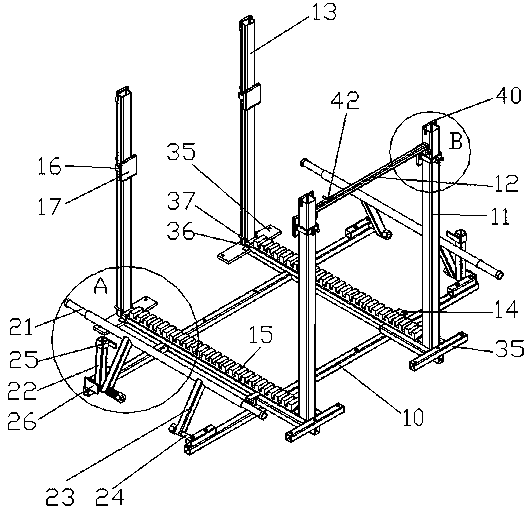

[0025] The coaming box liner 2 includes a base 10, a pair of L-shaped pillars 11, a pair of pillar connecting rods 12 and a pair of side pressure rods 13, the base 10 is fixed on the bottom plate 3 of the box through screws, and the level of the pair of L-shaped pillars 11 The parts are detachably mounte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com