An enhanced antifouling polymer coating with self-healing properties and its preparation

A polymer coating and enhanced technology, which is applied in the field of enhanced anti-fouling polymer coating and its preparation, can solve the problems of easy damage and poor mechanical properties, and achieve enhanced adhesion and poor mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

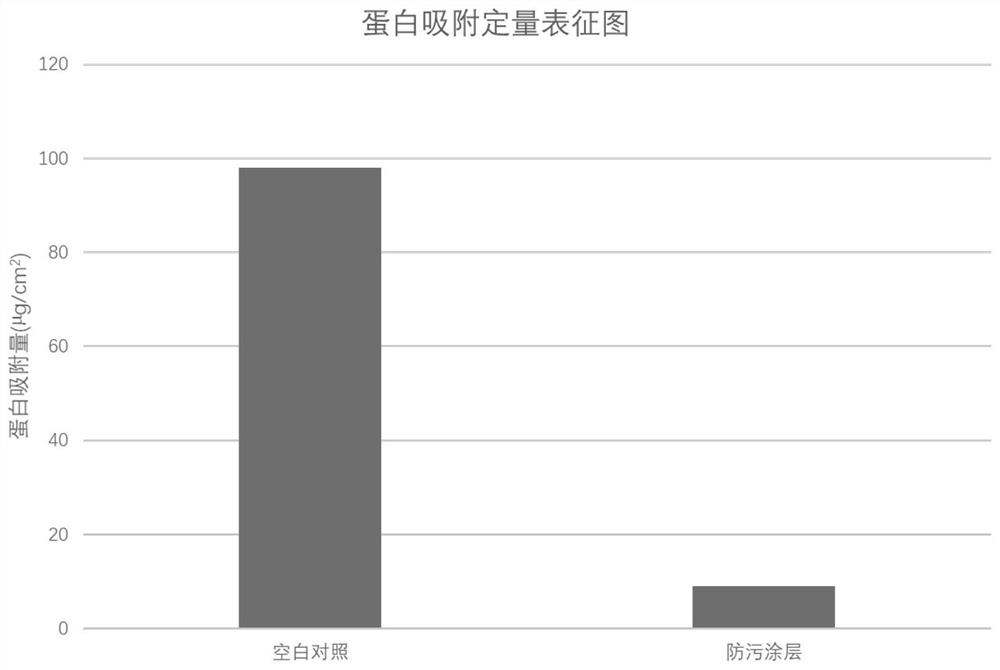

Examples

Embodiment 1

[0052] (1) Dissolve the intercalation agent cetyltrimethylammonium bromide (CTAB) in deionized water to prepare a solution with a concentration of 1 wt%, then add equal mass of montmorillonite higher than 300 mesh and stir at high speed , total solution weight 100g. Sonicate for another 5 minutes to make it disperse as evenly as possible. The dispersion was centrifuged and washed at high speed to remove excess intercalation agent, and finally the modified montmorillonite was obtained by freeze-drying, which was dissolved in tetrahydrofuran solvent to prepare a 0.1g / mL solution, which was removed through a 40μm filter head. For larger aggregates, a clear dispersion was obtained for later use.

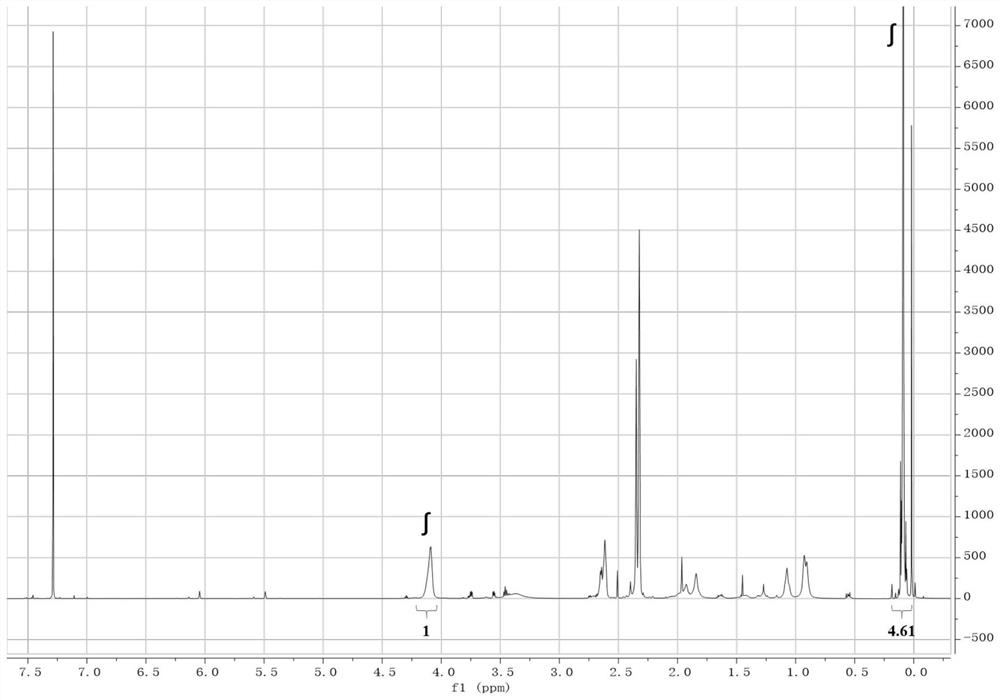

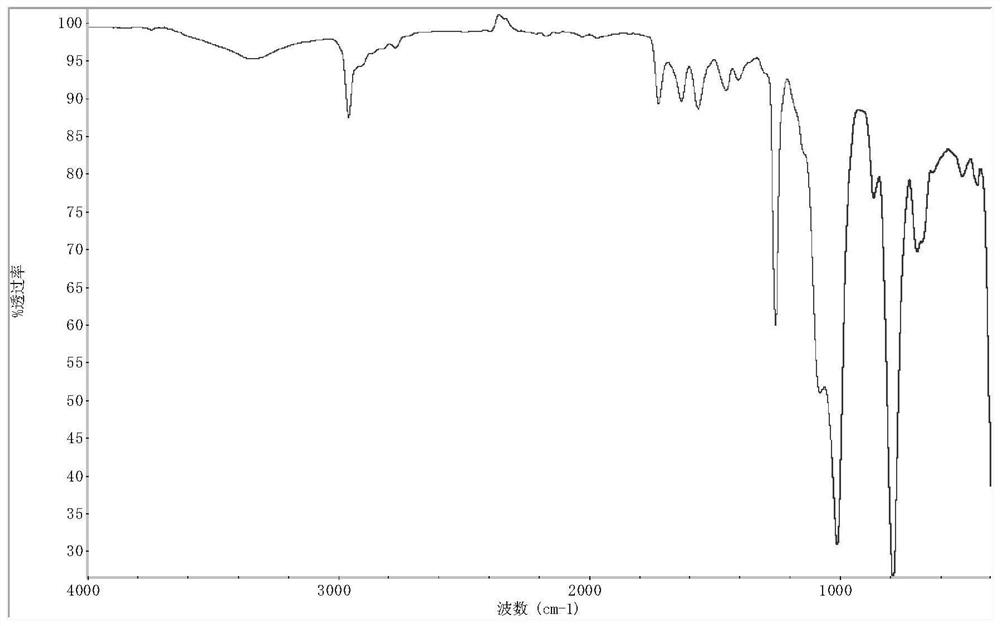

[0053] (2) 2 parts of 2,2'-bipyridine, 1 part of Br-PDMS-Br (2g), 200 parts of dimethylaminoethyl methacrylate, 10 mL of mixed solvent of n-propanol and 2-butanone (volume ratio of 7 / 3) Add it into a 50mL inclined two-necked flask, and vacuumize the closed system with nitrogen at a low...

Embodiment 2

[0059] (1) Dissolve the intercalation agent cetylpyridinium bromide (CPB) in deionized water to prepare a solution with a concentration of 5wt%, then add bentonite with an equal mass higher than 300 mesh and stir at a high speed, the total weight of the solution is 100g . Sonicate for another 10 minutes to make it disperse as evenly as possible. The dispersion liquid was centrifuged and washed at high speed to remove excess intercalation agent, and finally the modified bentonite was obtained by freeze-drying, which was dissolved in tetrahydrofuran solvent and prepared into a 0.1g / mL solution, which was removed through a 40μm filter head. The agglomerates were obtained to obtain a clear dispersion for later use.

[0060] (2) 2 parts of pentamethyldiethylenetriamine, 0.5 parts of Br-PDMS-Br (2g), 200 parts of methacrylic acid, 10 mL of mixed solvent of n-propanol and 2-butanone (volume ratio is 7 / 3) Add it into a 50mL oblique two-necked flask, and vacuumize the closed system w...

Embodiment 3

[0063] (1) The intercalation agent sodium dodecylbenzenesulfonate (SDS) is dissolved in deionized water to prepare a solution with a concentration of 10wt%, and then kaolin of equal mass higher than 300 mesh is added and stirred at high speed, the total weight of the solution is 100g. Sonicate for another 15 minutes to make it disperse as evenly as possible. The dispersion was centrifuged and washed at high speed to remove the excess intercalation agent, and finally the modified kaolin was obtained by freeze-drying, which was dissolved in tetrahydrofuran solvent and prepared into a 0.1g / mL solution, which was removed through a 40μm filter head. The agglomerates were obtained to obtain a clear dispersion for later use.

[0064] (2) 2 parts of 2,2'-bipyridine, 2 parts of Br-PDMS-Br (2g), 200 parts of hydroxyethyl acrylate, 10 mL of mixed solvent of n-propanol and 2-butanone (volume ratio is 7 / 3) Add it into a 50mL oblique two-necked flask, and vacuumize the closed system with ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com