Disk hill-shaped part in flat knitting machine

A flat knitting machine, center position technology, applied in the dish mountain field in the flat knitting machine, can solve problems such as fabric damage, achieve the effect of relieving coil tension and avoiding tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

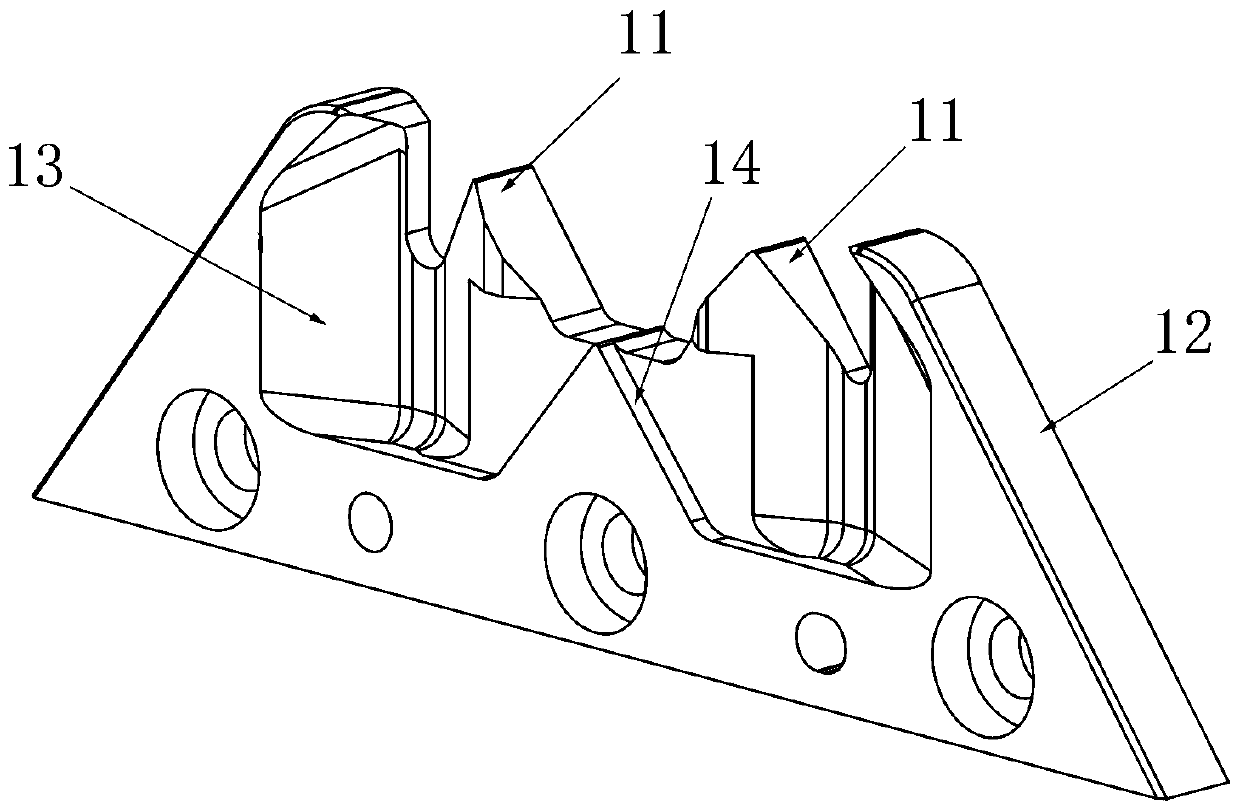

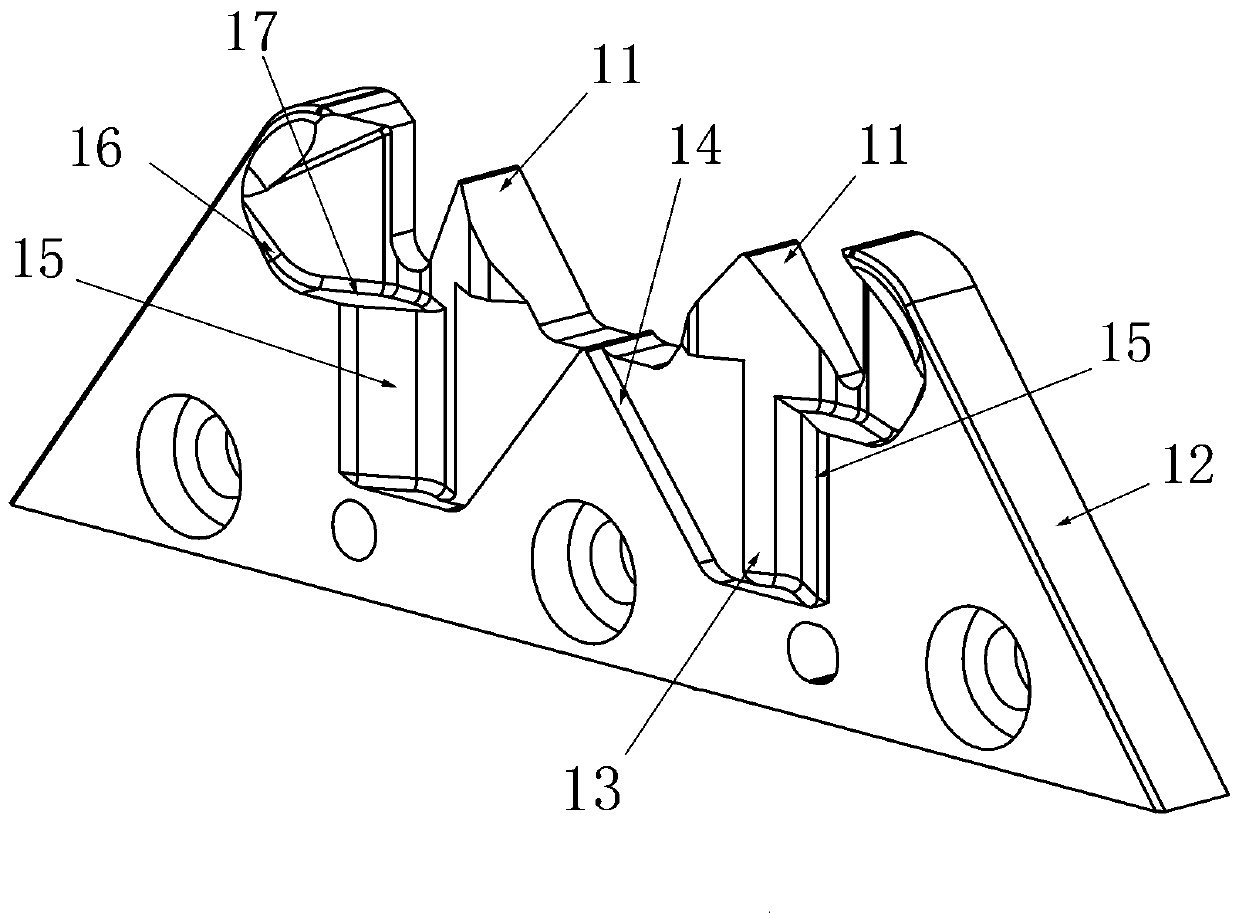

[0016] See attached picture. The butterfly mountain 1 described in this embodiment includes a left-right symmetrical trapezoidal body along the central vertical line. The upper edge of the body is composed of two inverted V-shaped needle running surfaces 11. The needle surface forms an acute angle with the lower edge of the body, and a concave portion 13 is provided on the surface of the body, so that the width of the inverted V-shaped needle surface is smaller than the width of the needle surface, and a triangular boss 14 is provided at the middle of the concave portion 13, and the triangular convex The table 14 is arranged symmetrically with the central vertical line of the body; a needle-moving boss 15 is provided on both sides of the recessed part 13, which is symmetrically arranged on both sides of the triangular boss 14; the upper edge of the needle-moving boss 15 includes The first needle surface 16 arranged obliquely and the second needle surface 17 arranged horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com