Anti-floating anchor rod structure penetrating through water-rich gravel bottom layer and construction method thereof

An anti-floating anchor and gravel layer technology is applied in the fields of infrastructure engineering, sheet pile walls, protection devices, etc. Problems such as poor pile holding force, to achieve the effect of safe, stable and reliable structure, simple and smooth construction process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

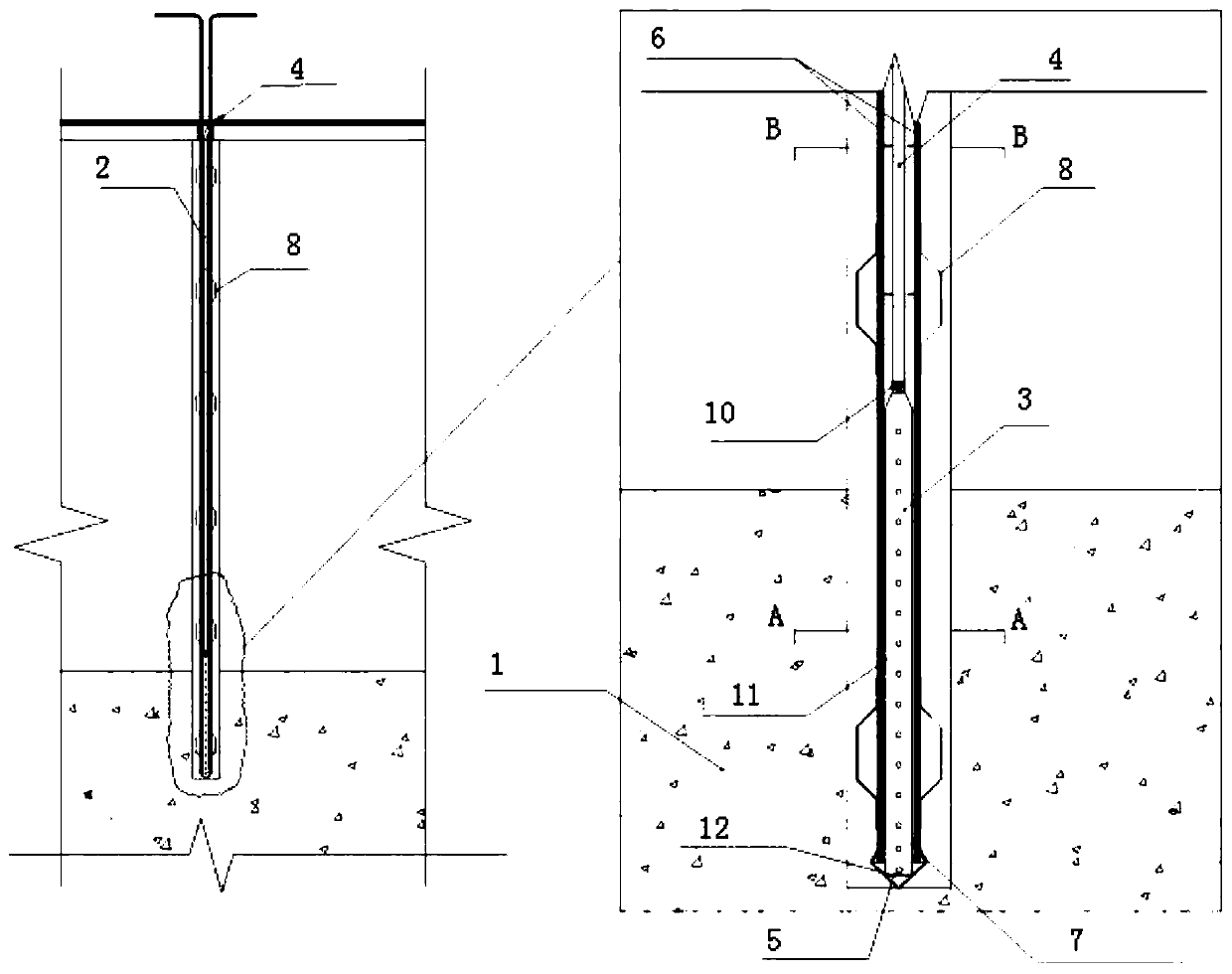

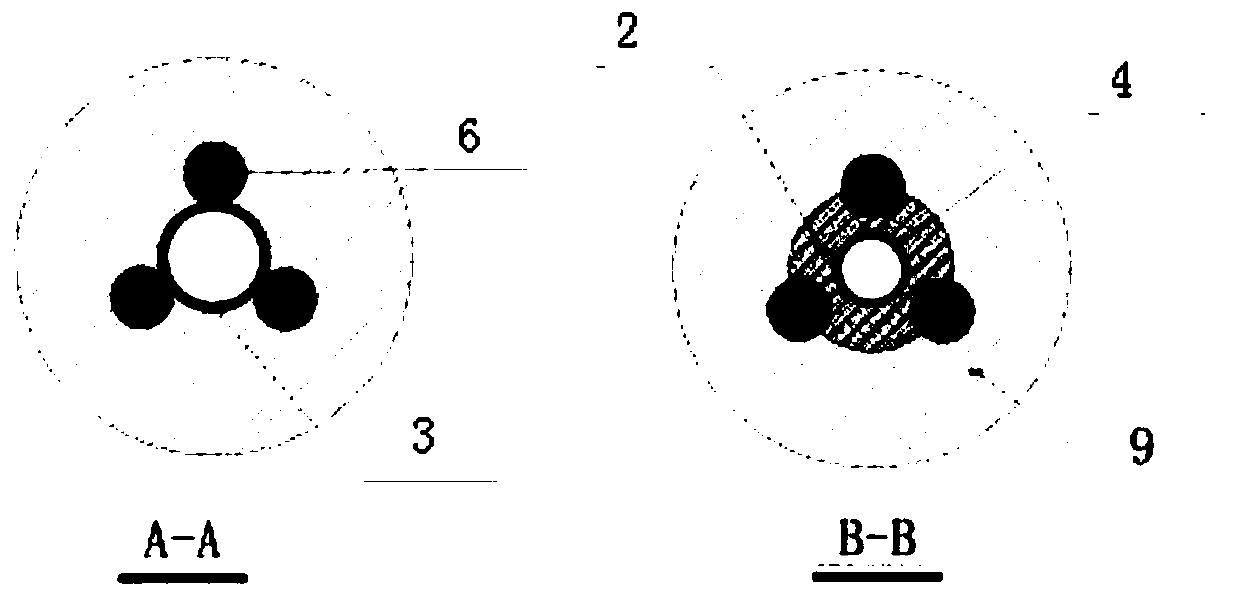

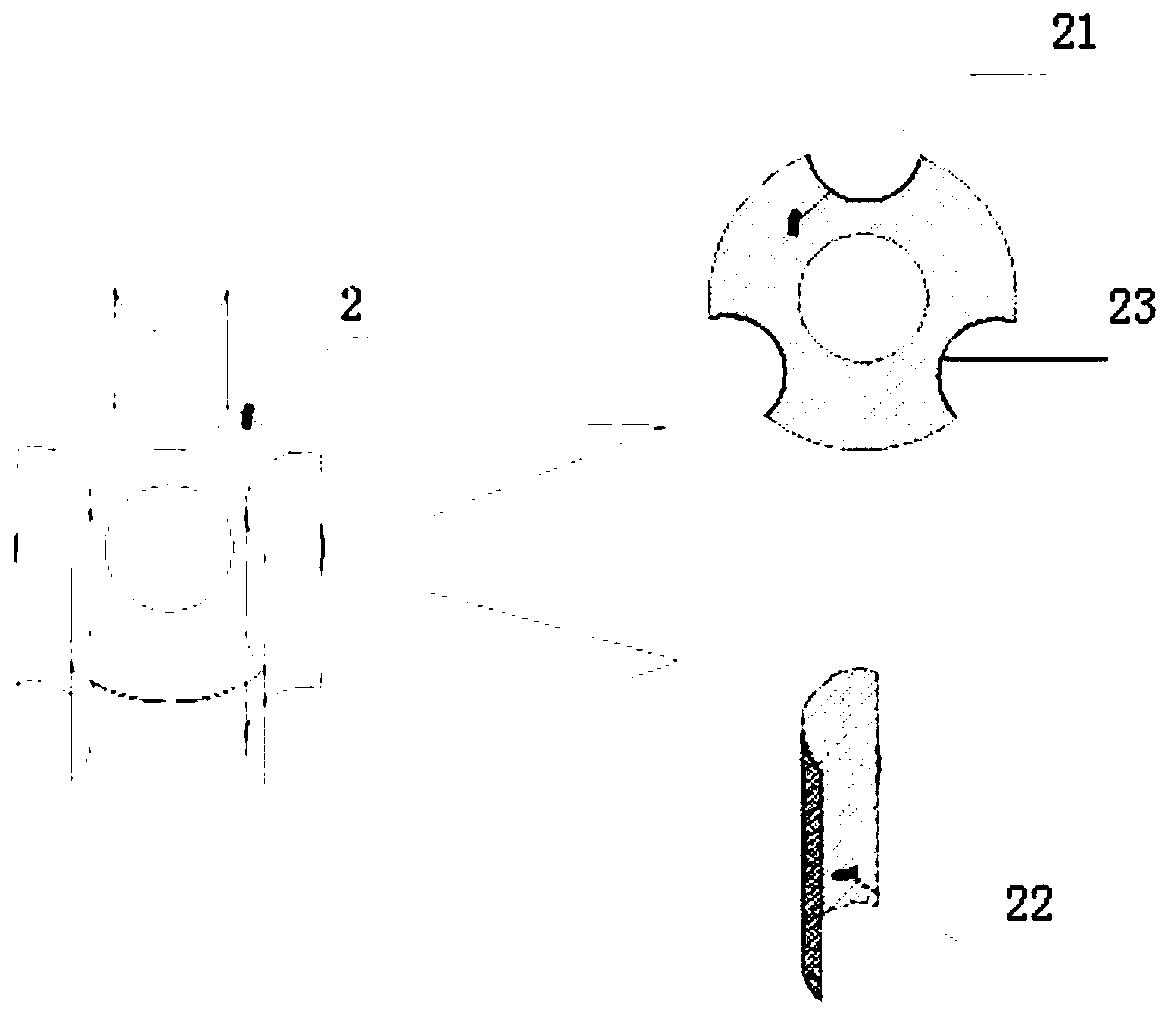

[0034] An anti-floating anchor structure for penetrating a water-rich gravel bottom layer, comprising a plurality of steel tendons 6 (ie, anti-floating anchors), fixing pieces 2, grouting flower tubes 3, grouting hoses 4, guide heads 5 and the like. Its anti-floating anchor rod is a steel tendon 6 composed of more than 3 steel bars. The steel tendons 6 are longitudinally arranged in parallel and are fixed by the fixing piece 2. The bottom ends of the steel tendons 6 extend to the bottom layer of water-rich gravel. Vertically arranged, the bottom end of the grouting flower tube 3 is provided with a guide head 5 . The fixed piece 2 is composed of an inner support piece 21 and a number of longitudinal galvanized binding pieces 22, the inner support piece 21 is arranged horizontally, the galvanized tie piece 22 is arranged vertically, and the outer circumference of the inner support piece 21 is evenly provided with a number of inner support card slots 23. The galvanized binding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com