Structure for improving rigidity of rotor

A rigidity and rotor technology, applied in the structural field of improving the rigidity of the rotor, can solve problems such as resonance, achieve the effect of prolonging the operating life, simple and reliable connection structure, and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

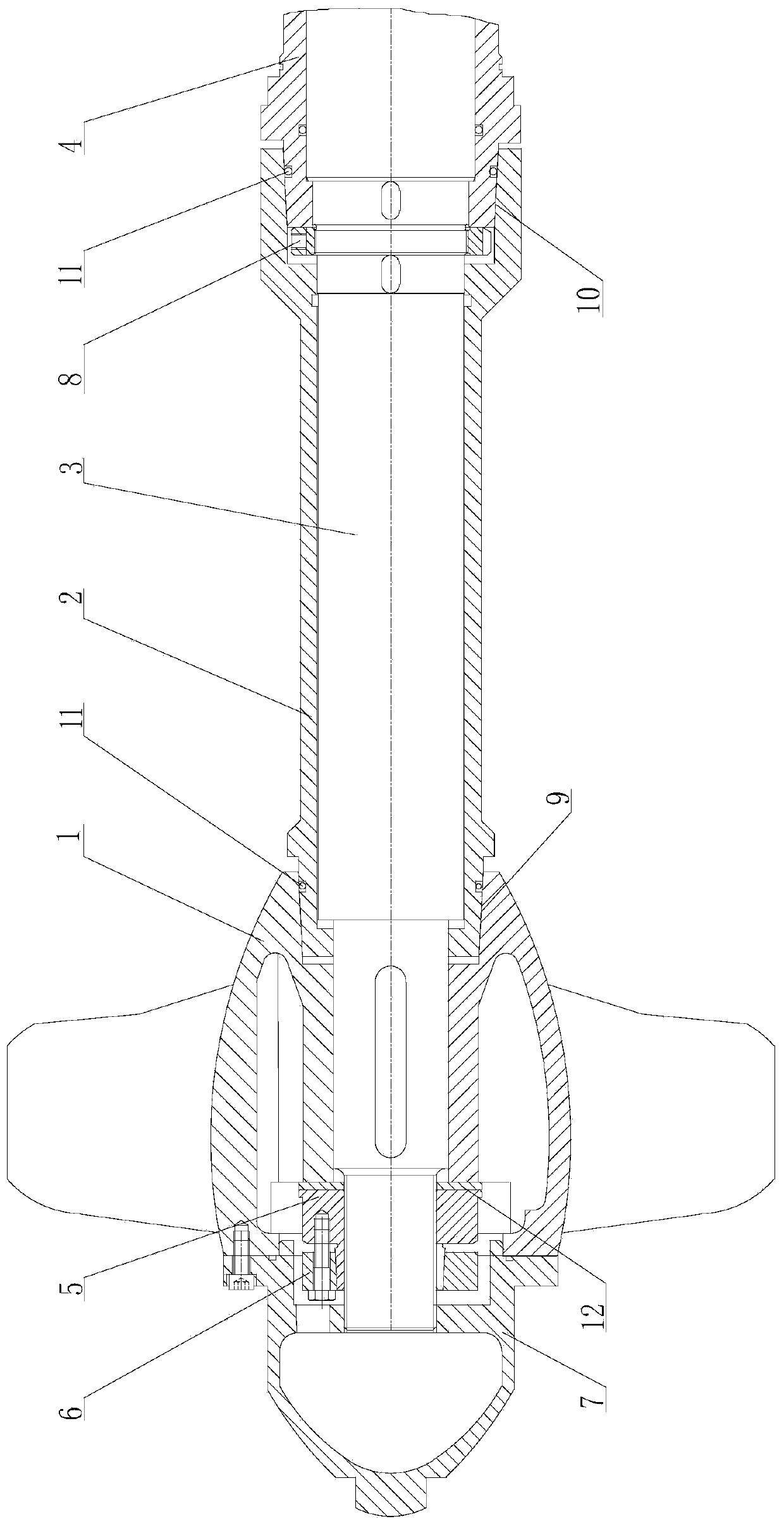

[0013] Example: as attached figure 1 As shown, this structure for improving the rigidity of the rotor includes an impeller hub 1, an impeller sleeve 2, a shaft 3, and a mechanical seal sleeve 4. The shaft 3 is sleeved with an impeller sleeve 2, and the left end of the impeller sleeve 2 A tapered surface is provided on the outer circular surface of the impeller hub 1 and matched with the inner circular surface of the right end of the impeller hub 1 to form a conical connection. The outer circular surface of the right end of the impeller sleeve 2 is provided with a tapered surface and is connected with The conical surfaces arranged on the inner circular surface of the left end of the mechanical seal sleeve 4 cooperate with each other to form a conical connection; the left end of the shaft 3 is fixedly connected to the impeller hub 1 through the impeller nut 5 and locked with the conical sleeve 6, A washer 12 is arranged between the impeller nut 5 and the impeller hub 1. A water gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com