Method, device and equipment for preventing overcurrent of three-phase motor, and storage medium

A three-phase current, three-phase motor technology, used in the control of electromechanical transmission, control of generators, motor-generator control, etc., can solve problems such as phase current overcurrent faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

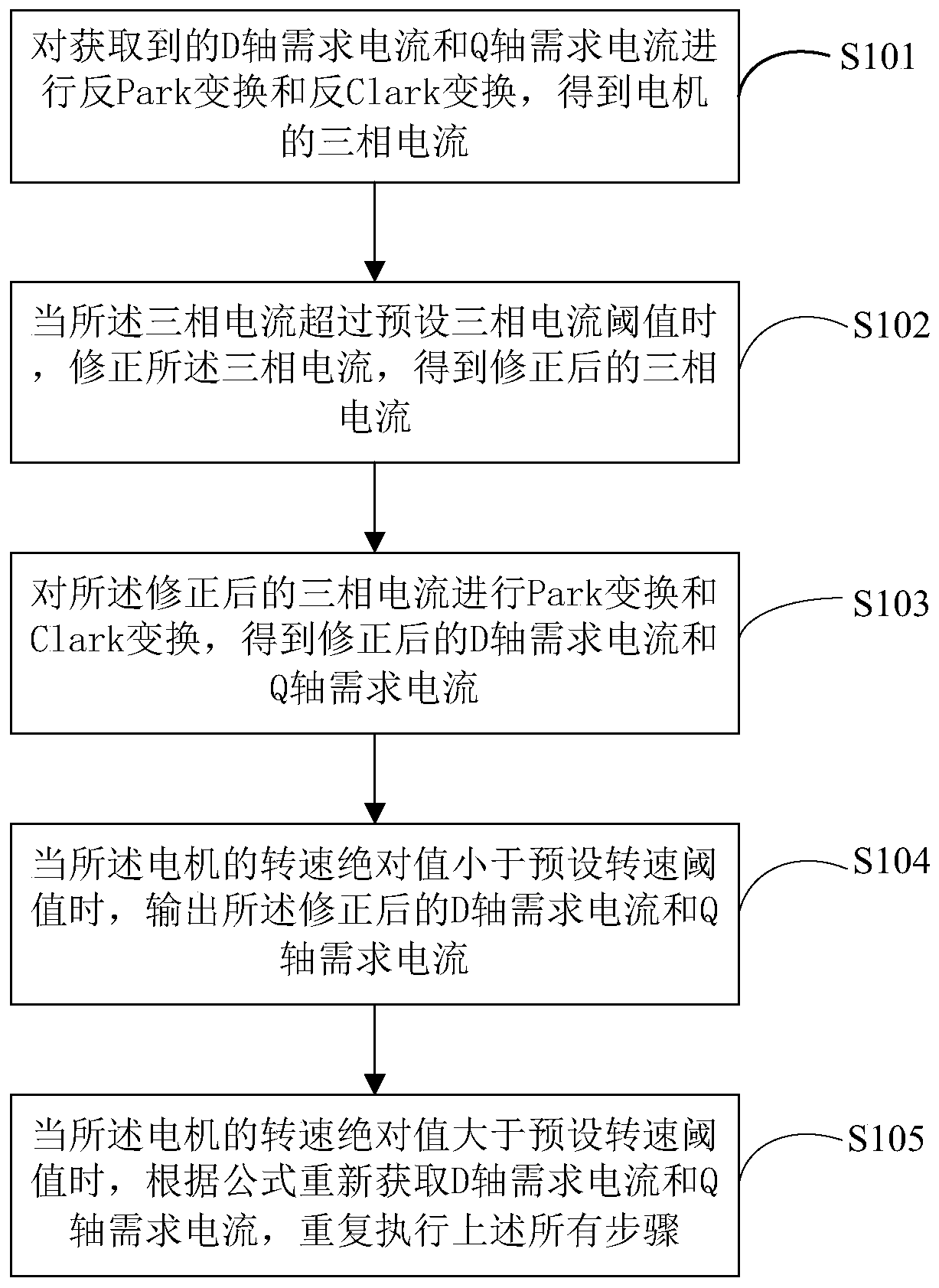

[0045] An embodiment of the present disclosure provides a method for preventing overcurrent of a three-phase motor, figure 1 It is a schematic flowchart of a method for preventing overcurrent of a three-phase motor according to an exemplary embodiment.

[0046] Such as figure 1 As shown, a method to prevent overcurrent of a three-phase motor includes:

[0047] S101 performs inverse Park transformation and inverse Clark transformation on the obtained D-axis demand current and Q-axis demand current to obtain the three-phase current of the motor;

[0048] Specifically, before inverse Park transformation and inverse Clark transformation are performed on the obtained D-axis demand current and Q-axis demand current, it also includes obtaining the D-axis demand current and Q-axis demand current of the motor, where the query torque- The speed-D-axis ammeter and torque-speed-Q-axis ammeter can directly obtain the required D-axis current and Q-axis current, or directly obtain the D-ax...

Embodiment 2

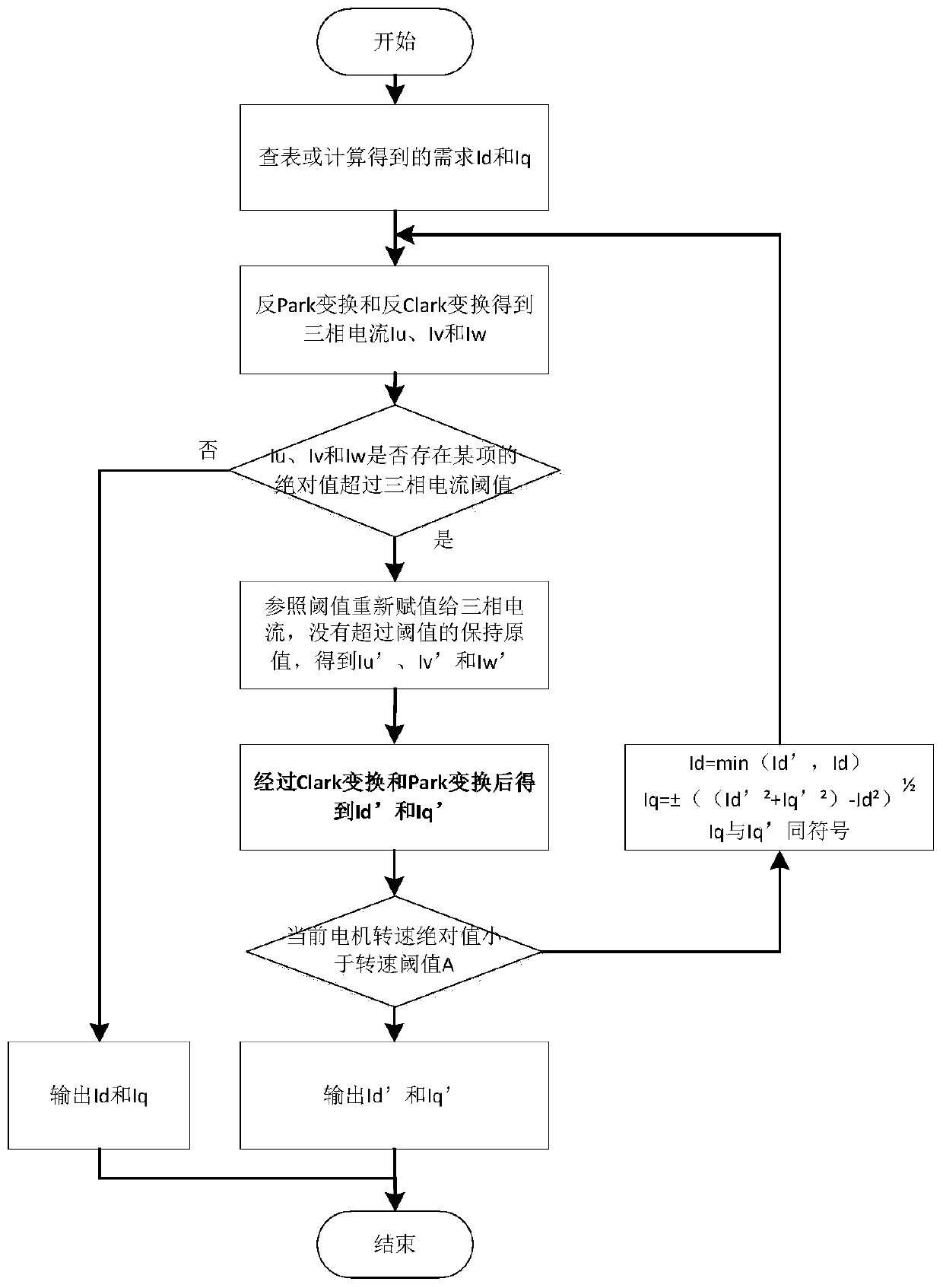

[0082] An embodiment of the present disclosure provides a method for preventing overcurrent of a three-phase motor, figure 2 It is a schematic flowchart of a method for preventing overcurrent of a three-phase motor according to an exemplary embodiment.

[0083] Such as figure 2 As shown, a method to prevent overcurrent of a three-phase motor includes:

[0084] Step 1: Directly obtain the required D-axis current and Q-axis current by querying the torque-speed-D-axis ammeter and torque-speed-Q-axis ammeter, or directly obtain the D-axis demand current and Q demand current through formula calculation.

[0085] Step 2: Perform inverse Park transformation and inverse Clark transformation on the acquired D-axis demand current and Q-axis demand current to obtain three-phase currents Iu, Iv and Iw of the motor.

[0086] Step 3: Determine whether any one of the three-phase currents Iu, Iv and Iw of the motor exceeds the preset phase current threshold. When any one of the three-phas...

Embodiment 3

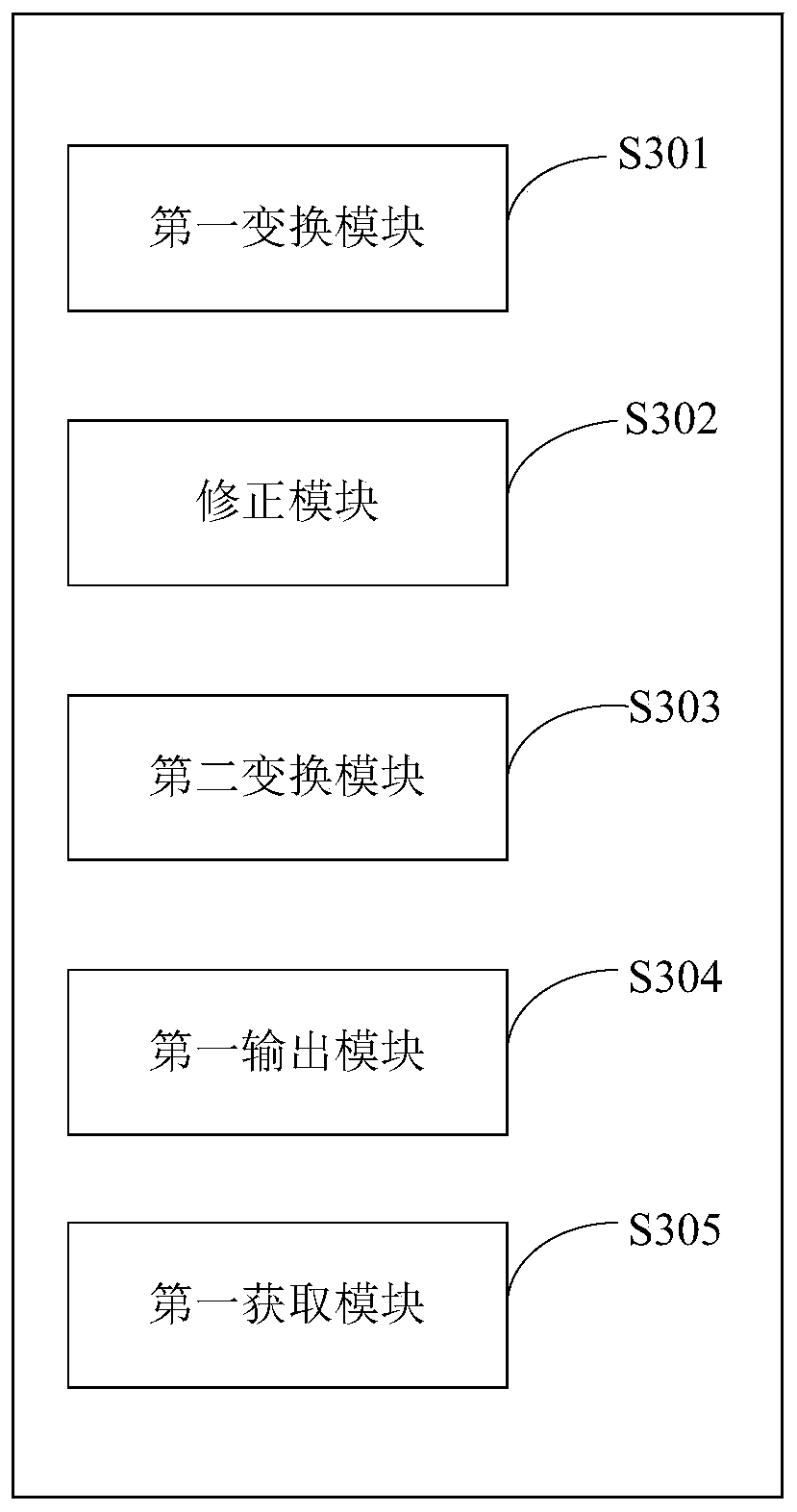

[0095] An embodiment of the present disclosure provides a device for preventing overcurrent of a three-phase motor, image 3 It is a structural schematic diagram of a device for preventing overcurrent of a three-phase motor according to an exemplary embodiment.

[0096] Such as image 3 As shown, in an embodiment of the present disclosure, a device for preventing overcurrent of a three-phase motor includes:

[0097] S301 The first transformation module is used to perform inverse Park transformation and inverse Clark transformation on the obtained D-axis demand current and Q-axis demand current to obtain the three-phase current of the motor;

[0098] S302 correction module, used to correct the three-phase current when the three-phase current exceeds the preset three-phase current threshold, and obtain the corrected three-phase current;

[0099] S303 The second transformation module is used to perform Park transformation and Clark transformation on the corrected three-phase cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com