Ribbon penetration mechanism and ribbon penetration method

A belt-passing and belt-threading technology, applied in the directions of cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of long time consumption, damaged belt-shaped elements, low belt-threading efficiency, etc., and achieves a simple and fast belt-threading process. , to avoid the effect of spatial orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

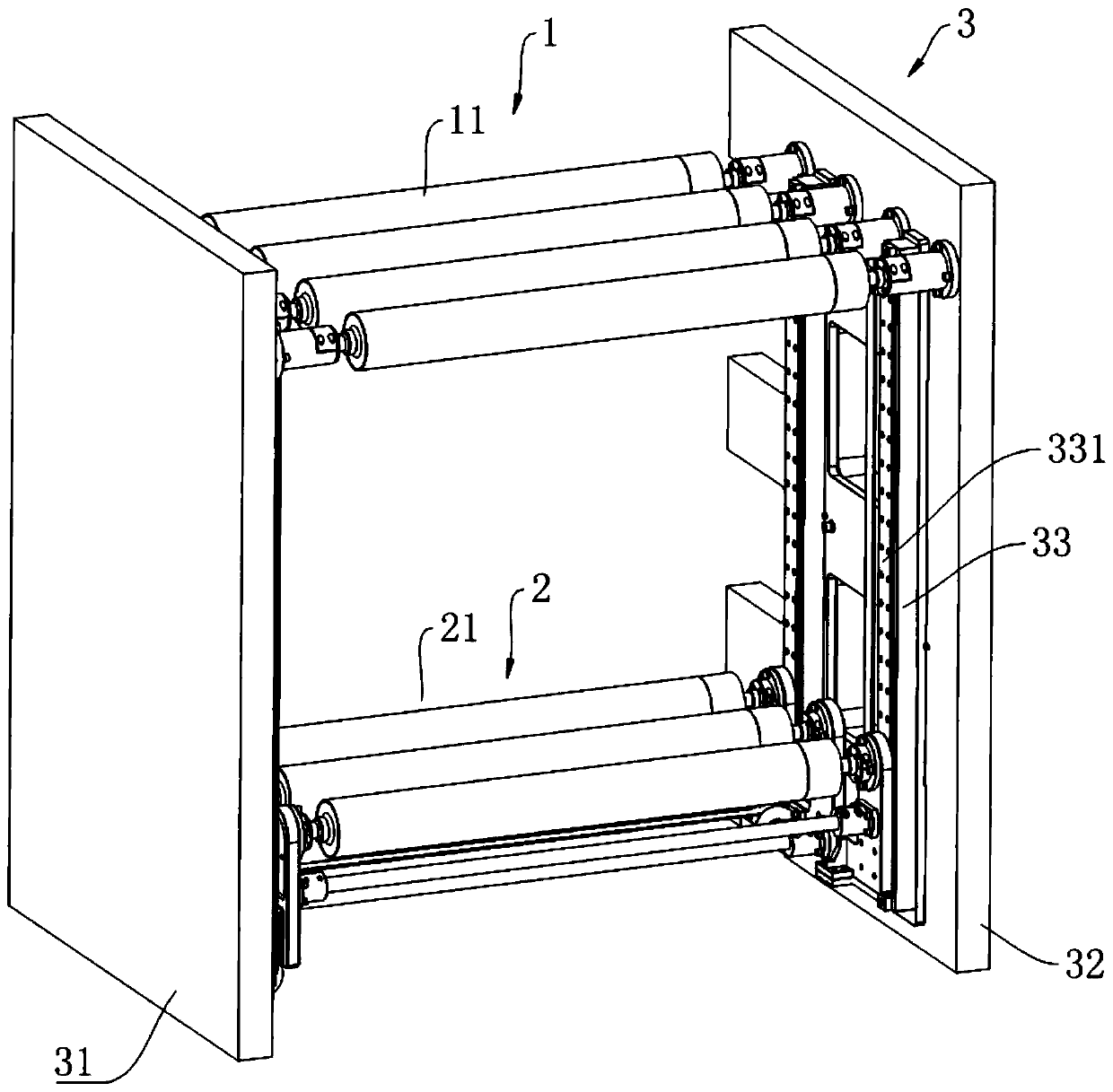

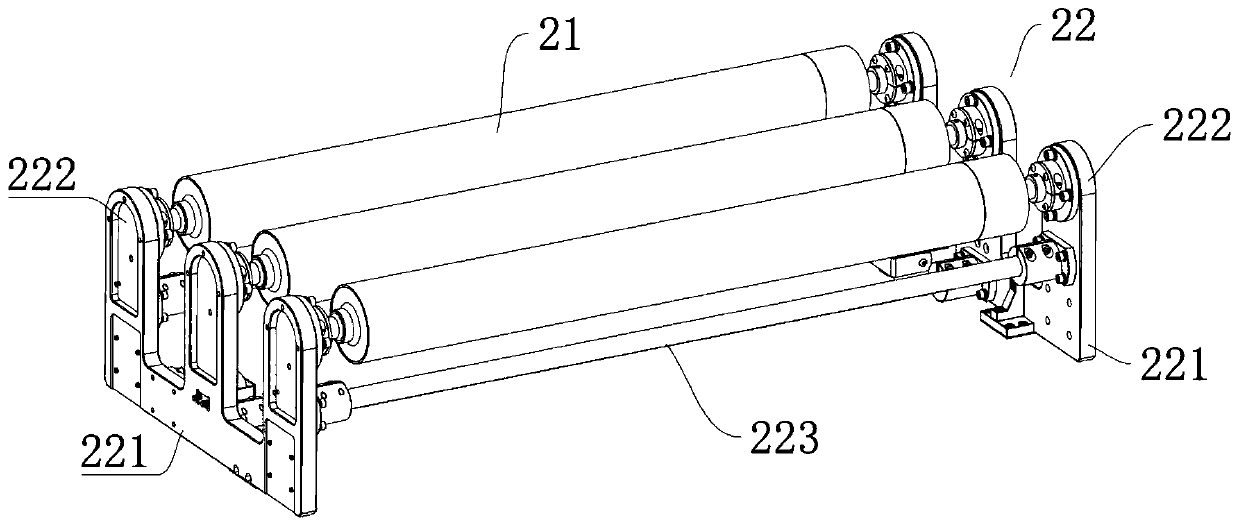

[0039] refer to figure 1 and figure 2 , figure 1 It is a structural schematic diagram of the belt passing mechanism in Embodiment 1, figure 2 It is another structural schematic diagram of the belt passing mechanism in the first embodiment. The strap-passing mechanism in this embodiment includes a first strap-passing assembly 1 and a second strap-passing assembly 2 , and the second strap-passing assembly 2 is located on one side of the first strap-passing assembly 1 . The first strap assembly 1 and the second strap assembly 2 are relatively moved, the first strap assembly 1 and the second strap assembly 2 are interlaced and act on the belt-shaped element, so that the belt-shaped element completes the belt-threading action.

[0040] In the belt-passing mechanism in this embodiment, when the relatively moving first belt-passing assembly 1 and the second belt-passing assembly 2 pass by alternately, they can act on the belt-shaped element, so that the belt-shaped element is pass...

Embodiment 2

[0059] The belt threading method in the present embodiment is realized based on the belt passing mechanism in the first embodiment, which specifically includes the following steps:

[0060] The first strap assembly 1 and the second strap assembly 2 are relatively moved, the first strap assembly 1 and the second strap assembly 2 are interlaced and act on the belt-shaped element, so that the belt-shaped element completes the belt-threading action.

[0061] Through the staggered movement of the second belt-passing assembly 2 and the first belt-passing assembly 1, it acts on the belt-shaped element, so that the belt-shaped element completes the belt-threading action, so that the whole process of belt-threading is simple and convenient, and there is no need to perform multiple operations according to the belt-running path. Second threading, thus reducing threading time, improving threading efficiency, and avoiding damage to tape elements.

[0062] refer to Figure 4 and Figure 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com