Multifunctional operation ladder trolley

A multi-functional and operational technology, applied in ladders, buildings, building structures, etc., can solve problems such as differences in the height of construction locations, inability to use locking devices, and short operating periods such as skylights.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

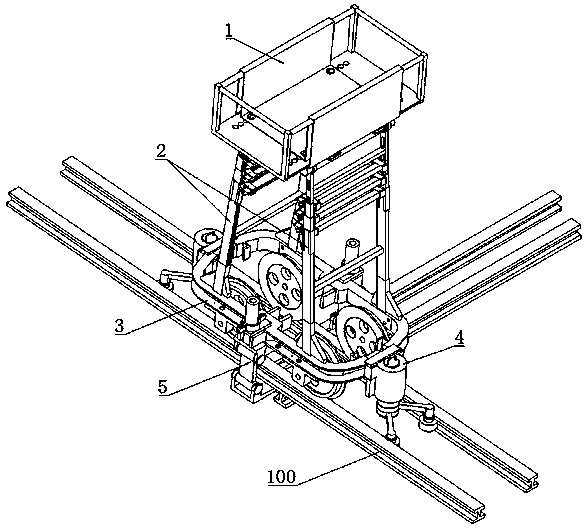

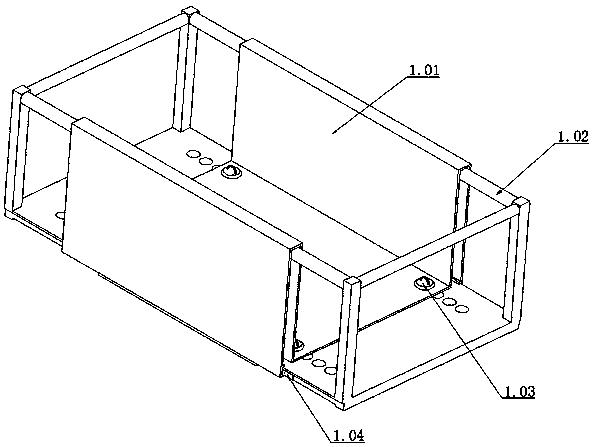

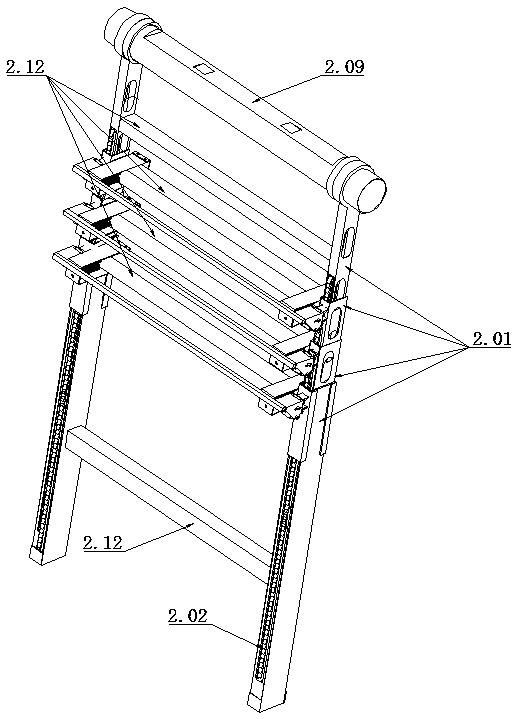

[0051] This embodiment provides a kind of multifunctional operation ladder car, comprises working platform 1, support frame 2, chassis 3 and the end portion anti-tipping device 4 that is arranged on the two ends of chassis 3; Working platform 1 is arranged on the top of support frame 2; 3 is arranged at the bottom of the support frame 2, and the chassis 3 is provided with a track wheel 3.01 for walking on the track 100; the end anti-tipping device 4 includes a pawl shaft 4.01, a pawl bushing 4.02, and an upper profiling limit Rod 4.03, lower profiling limit rod 4.04 and bottom cover 4.05; pawl shaft 4.01 is provided with upper pawl 4.06 and lower pawl 4.07 along the axial direction; The first spring 4.08 is connected with the ratchet installation hole of the ratchet shaft 4.01; the ratchet bushing 4.02 is connected with the chassis 3, and is provided with a first special-shaped shaft hole 4.09 which is sequentially connected by a plurality of first arc-shaped grooves, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com