Heat exchanger

A heat exchanger and diffuser technology, applied in heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve problems such as flow distribution damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

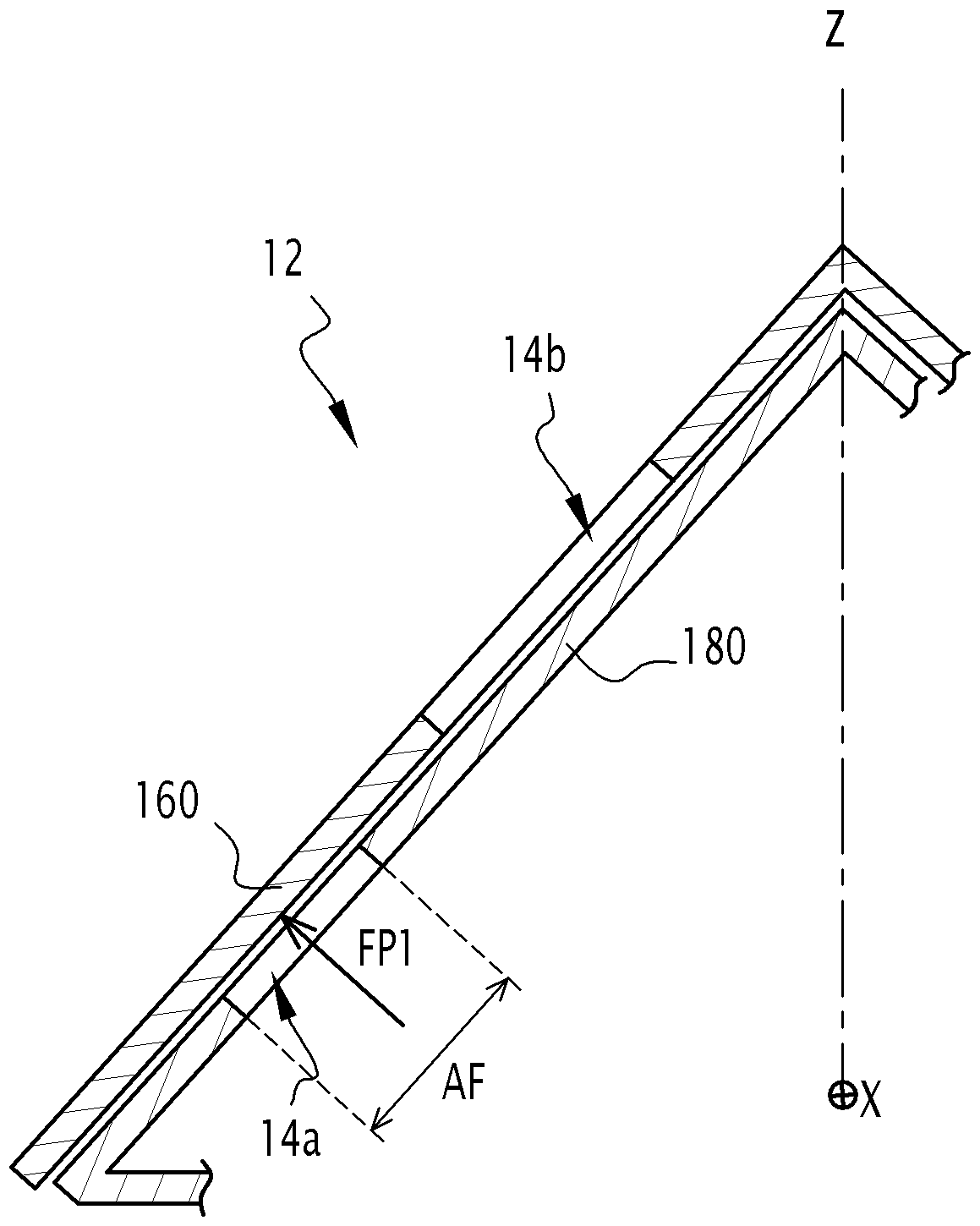

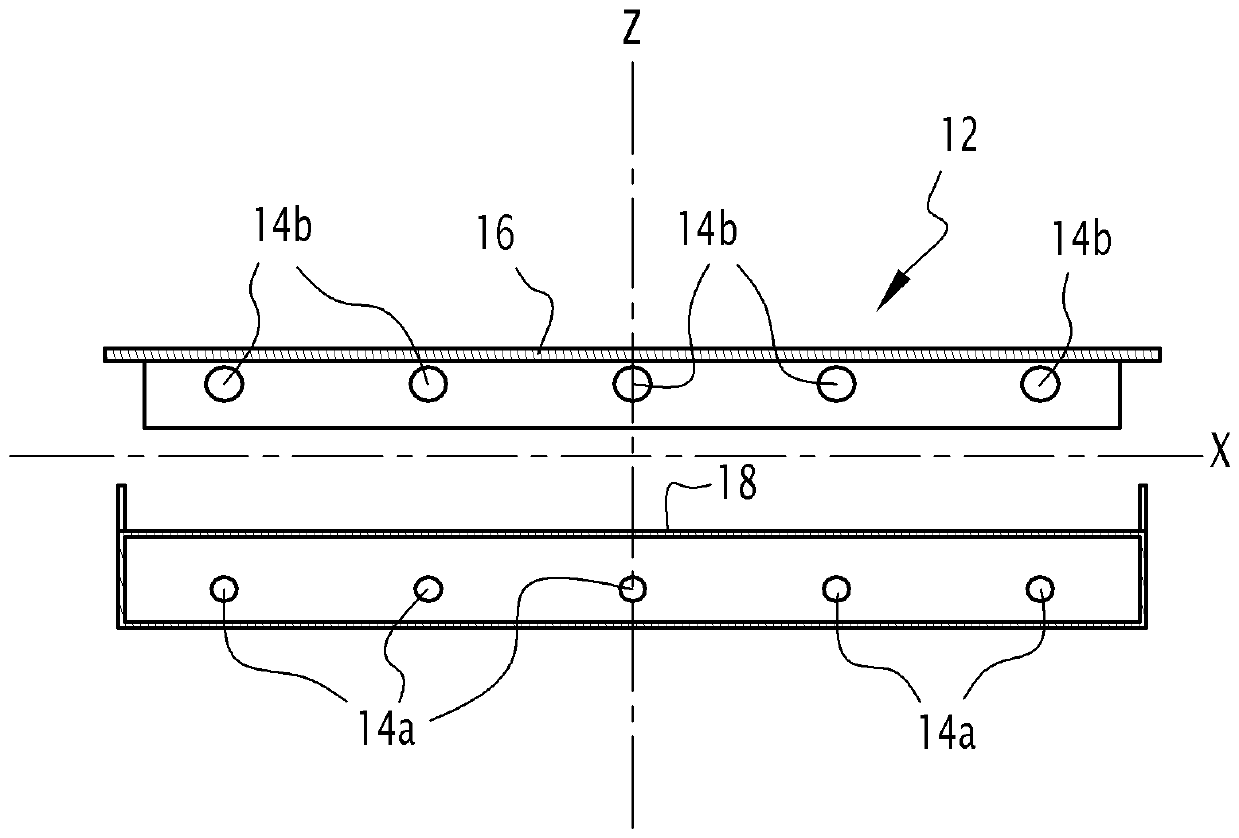

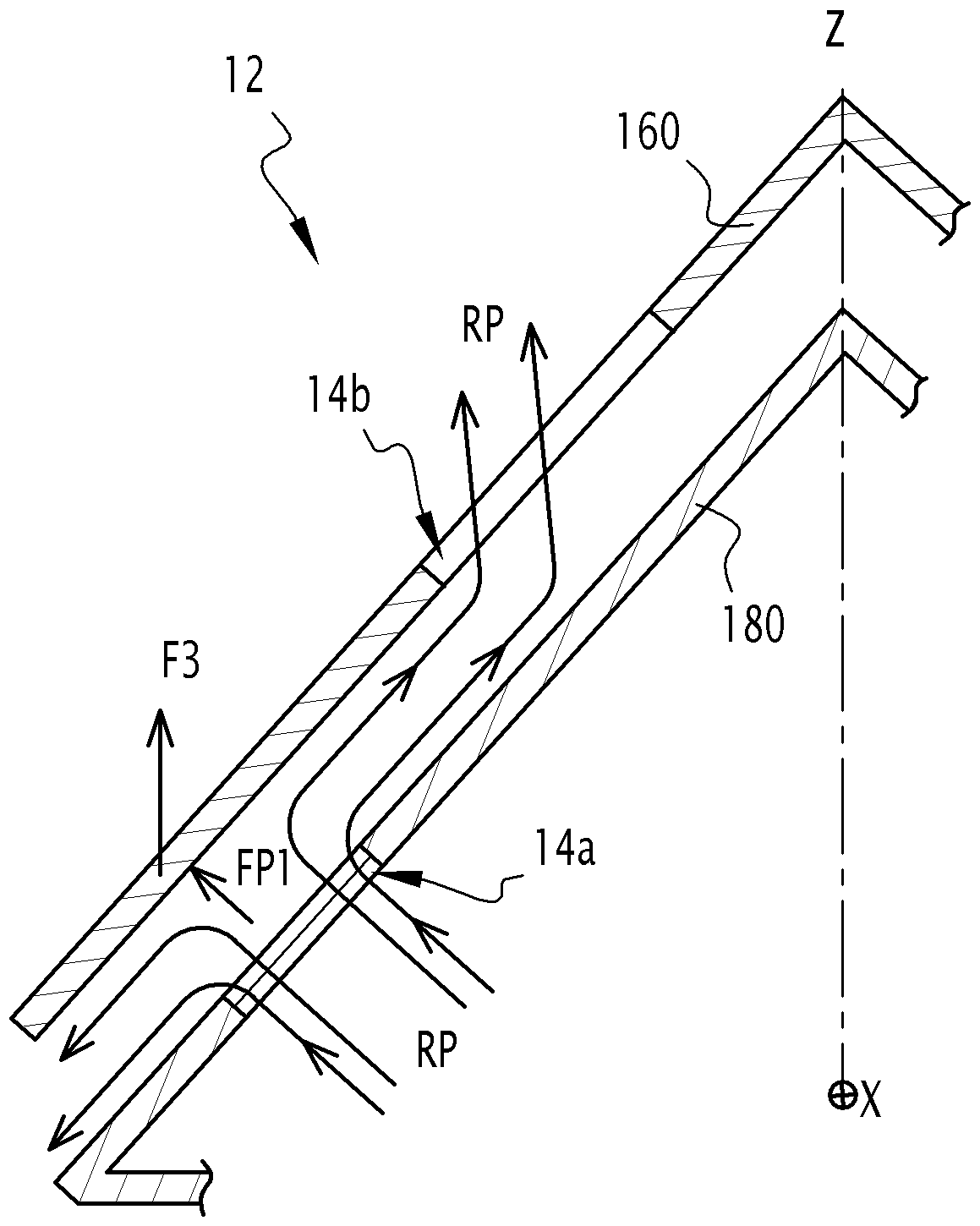

[0025] figure 1 A heat exchanger in the form of a submerged evaporator 2 is shown, eg for a refrigeration circuit of a cooler. The submerged evaporator 2 comprises a casing 4 extending along a longitudinal axis X. The casing 4 has a substantially cylindrical shape centered on an axis parallel to the longitudinal direction X.

[0026] The submerged evaporator 2 comprises an inlet pipe 6 and an outlet or suction pipe 8 through which refrigerant flows along the figure 1 Arrows F1 and F2 in enter into and leave from the housing 4 respectively. The submerged evaporator 2 also comprises a tube bundle 10 spanning the shell 4 along the longitudinal axis X. A tube bundle 10 is provided for circulating a flow of water to be cooled in the housing 4 .

[0027] exist figure 1 Above, the tube 10 is shown filling most of the upper half of the shell 4 . However, other distributions of tubes 10 are possible. In particular, the upper quarter of the housing 4 may be free from the tube 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com