Underwater drawing body passive heave compensation system based on constant pressure difference

A passive heave compensation, underwater tow body technology, applied in tow/push equipment, ship parts, transportation and packaging, etc., can solve the compensation system's poor adaptive ability and robustness, difficult steady-state operating point, and bulky volume. and other problems, to achieve the effect of improving the heave compensation accuracy, simple structure and improving ship loadability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

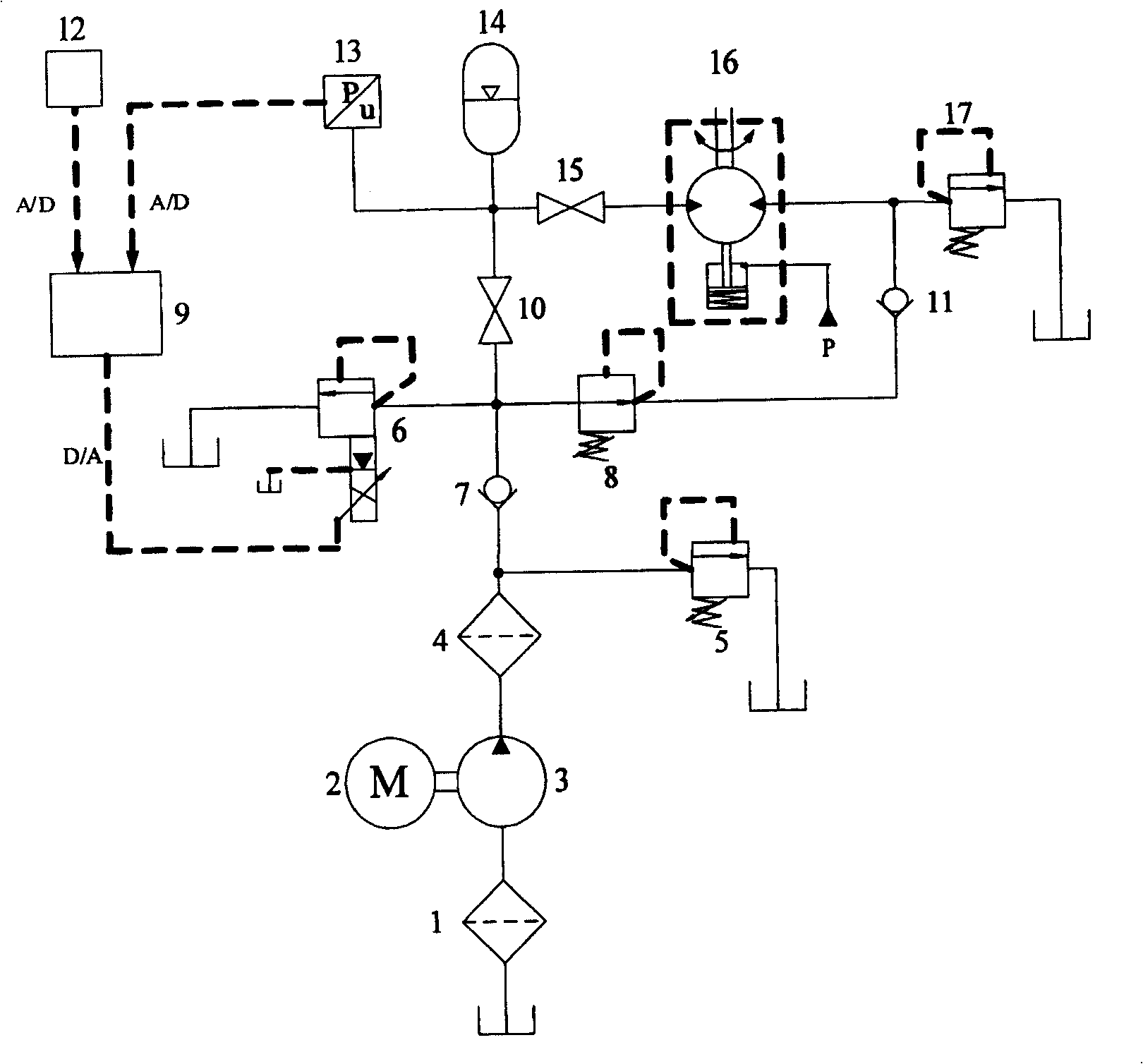

[0016] As shown in the drawings, the present invention includes: the output end of the first one-way valve 7 in the oil supply system is divided into three routes, the first route is connected to the oil inlet of the proportional relief valve 6, and the second route is connected to the pressure reducing valve 8 The oil inlet, the third road is divided into three roads after passing through the first cut-off valve 10, the first road is connected to the pressure sensor 13, the second road is connected to the accumulator 14, and the third road is connected to the hydraulic motor through the second cut-off valve 15 16 High-pressure cavity, hydraulic motor 16 Low-pressure cavity is divided into two circuits, the first circuit is connected to the oil inlet port of the pilot relief valve 17, and the second circuit is connected to the oil outlet port of the pressure reducing val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com