Overpressure filtration system for nephrology department

A filtration system and constant pressure system technology, applied in the field of nephrology ultrafiltration, can solve problems such as unstable pressure, inability to ensure continuity of overpressure filtration, and flow interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

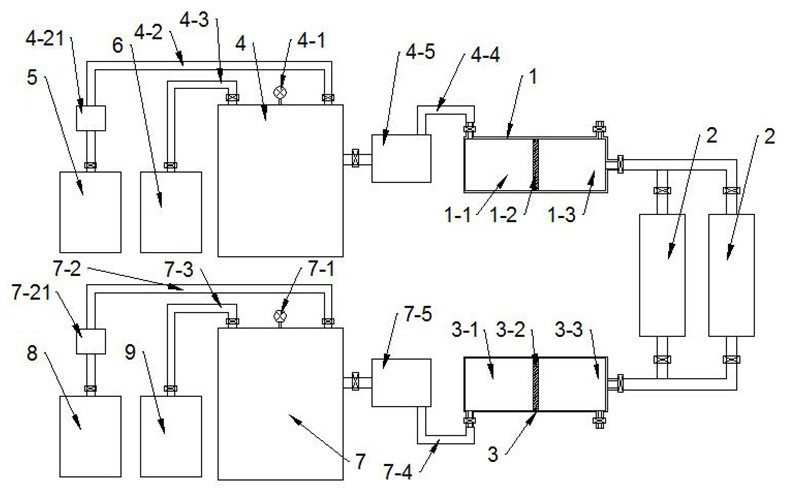

[0037] Embodiment 1, a kind of nephrology ultra-pressure filtration system, such as figure 1 , 5 , 6, including

[0038] The constant pressure overpressure system, the constant pressure overpressure system includes the first constant pressure system and the overpressure tank 1, the inside of the overpressure tank 1 is an overpressure gas chamber 1-1 separated by an overpressure partition 1-2 and an overpressure tank 1. The liquid chamber 1-3, the overpressure gas chamber 1-1 has an air inlet connected with the first constant pressure system and installed with a valve, and the overpressure liquid chamber 1-3 has a liquid inlet and a liquid outlet installed with a one-way valve , the first constant pressure system comprises the first constant pressure gas tank 4, the first booster tank 5 and the first decompression tank 6, the first pressure gauge is installed on the first constant pressure gas tank 4, the first constant pressure gas tank 4 It is connected with the first boost...

Embodiment 2

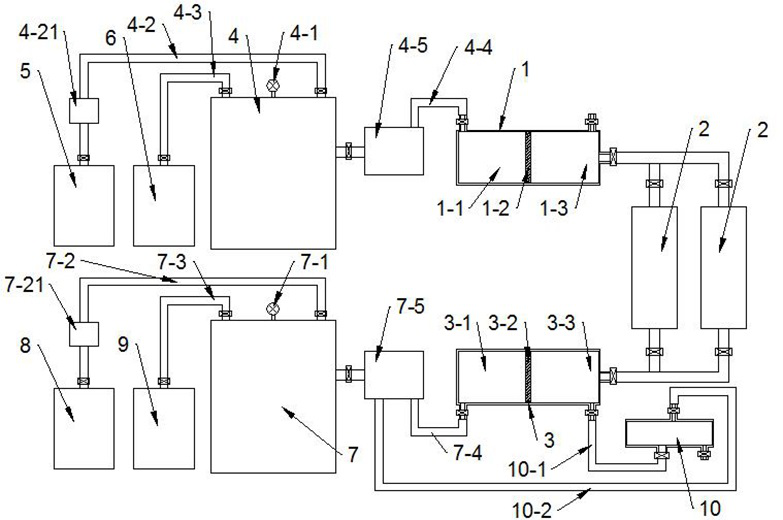

[0043] Example 2, such as figure 2 , 5 , 6, 8, 9 are basically the same as in Embodiment 1, the difference is that the nephrology superpressure filtration system also includes a buffer tank 10, and the bottom of the buffer tank 10 is provided with a liquid inlet and a liquid discharge with a check valve The interior of the buffer tank 10 is provided with an elastic sheet (elastic rubber sheet) that is close to the top surface and is tightly connected with the side wall around. , the liquid inlet of the buffer tank 10 communicates with the liquid outlet of the low-pressure liquid chamber, and a third communication pipe is connected between the air inlet of the buffer tank 10 and the fourth gas filter box.

Embodiment 3

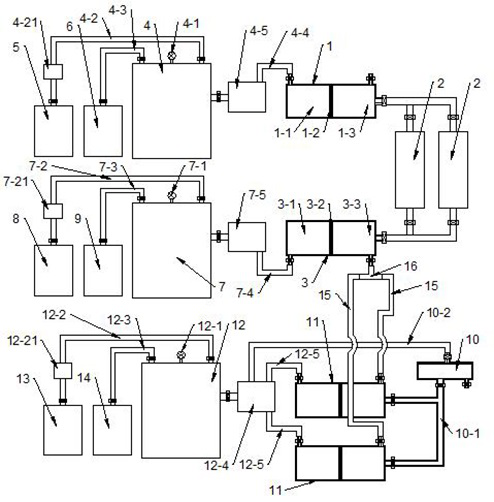

[0044] Example 3, such as image 3 , 4 , 5, 6, 7, 8, 9, are basically the same as Embodiment 1, the difference is that: the nephrology overpressure filtration system includes a steady flow system, and the steady flow system includes a third constant pressure system and at least one steady flow tank 11. The inside of the steady flow tank 11 is a steady flow gas chamber and a steady flow liquid chamber separated by a steady flow partition. The steady flow gas chamber has an air inlet connected to the third constant pressure system and installed with a valve. The steady flow The liquid chamber is provided with a liquid inlet and a liquid discharge port with a one-way valve, and the liquid inlet of the steady flow liquid chamber is communicated with the liquid discharge port of the low pressure liquid chamber through the steady flow pipeline 15. When there are two steady flow tanks 11, The liquid outlet of the low-pressure liquid chamber is connected to the tee pipe 16, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com