Stainless steel tube ultrasonic thickness measuring device with novel probe

A stainless steel tube, ultrasonic technology, applied in the direction of measuring devices, using ultrasonic/sonic/infrasonic, instruments, etc., can solve the problems of easy movement, measurement result error, etc., and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

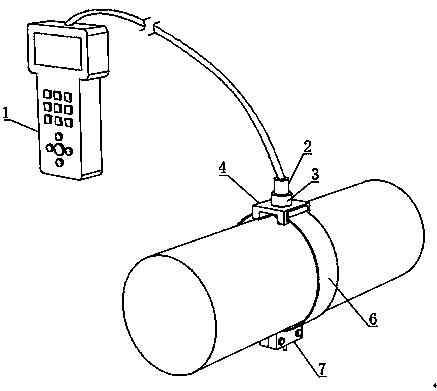

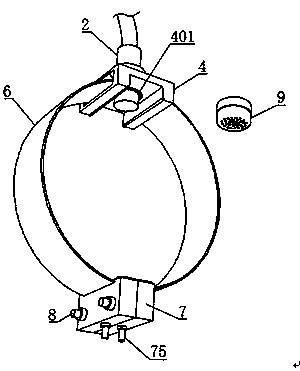

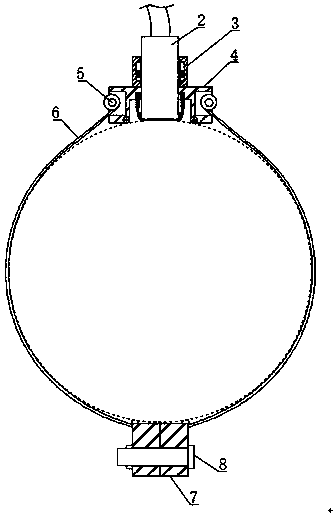

[0042] see figure 1 , a stainless steel tube ultrasonic thickness measuring device with a new type of probe, including a host 1, a probe body 2 and wires, the host 1 and the probe body 2 are electrically connected by wires, please refer to figure 2 and image 3 , the outer end of the probe body 2 is slidingly connected to the limit sleeve 3 and the U-shaped disk 4, and the lower end of the limit sleeve 3 is fixedly connected to the upper end of the U-shaped disk 4. Please refer to Figure 4 , the inner wall of the limiting sleeve 3 is provided with an annular groove 301, the outer end of the probe body 2 is fixedly connected to the limiting ring 10, and the limiting ring 10 is slidably connected to the inside of the annular groove 301, and through the limit ring 10 and the annular groove 301 Cooperate so that the probe body 2 can move up and down, which is convenient for measuring with the outer wall of the pipe. The left and right sides of the U-shaped disk 4 are provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com