Die cutting mechanism and die cutting machine

A die-cutting and die-cutting knife technology, applied in metal processing and other directions, can solve the problems of low tearing efficiency, multi-manpower, manual tearing, etc., to reduce the use of manpower and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

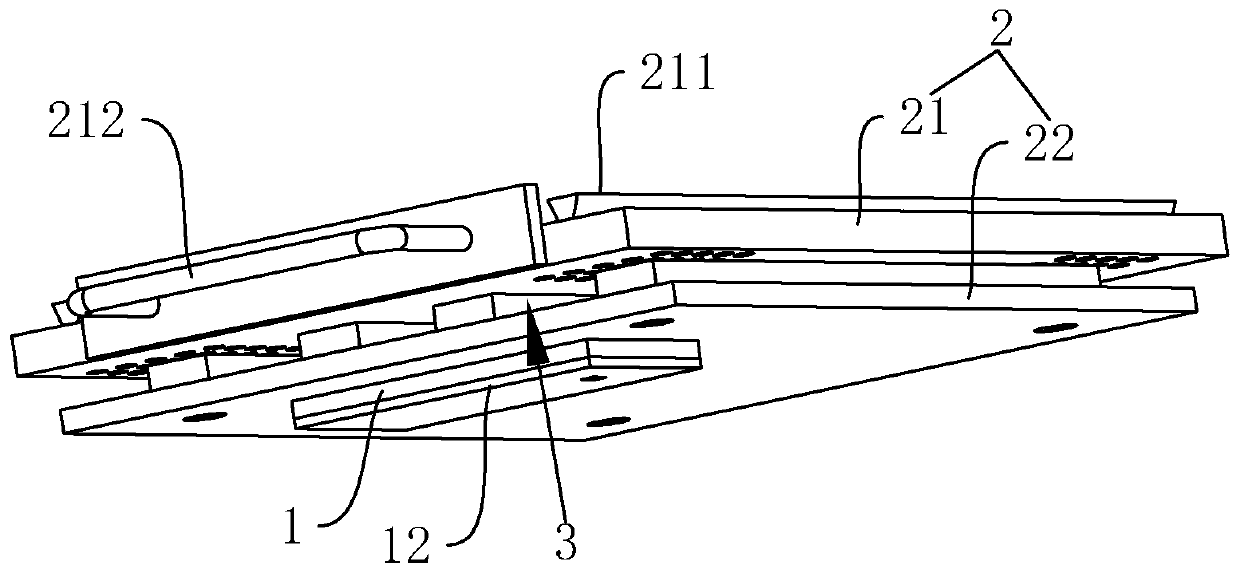

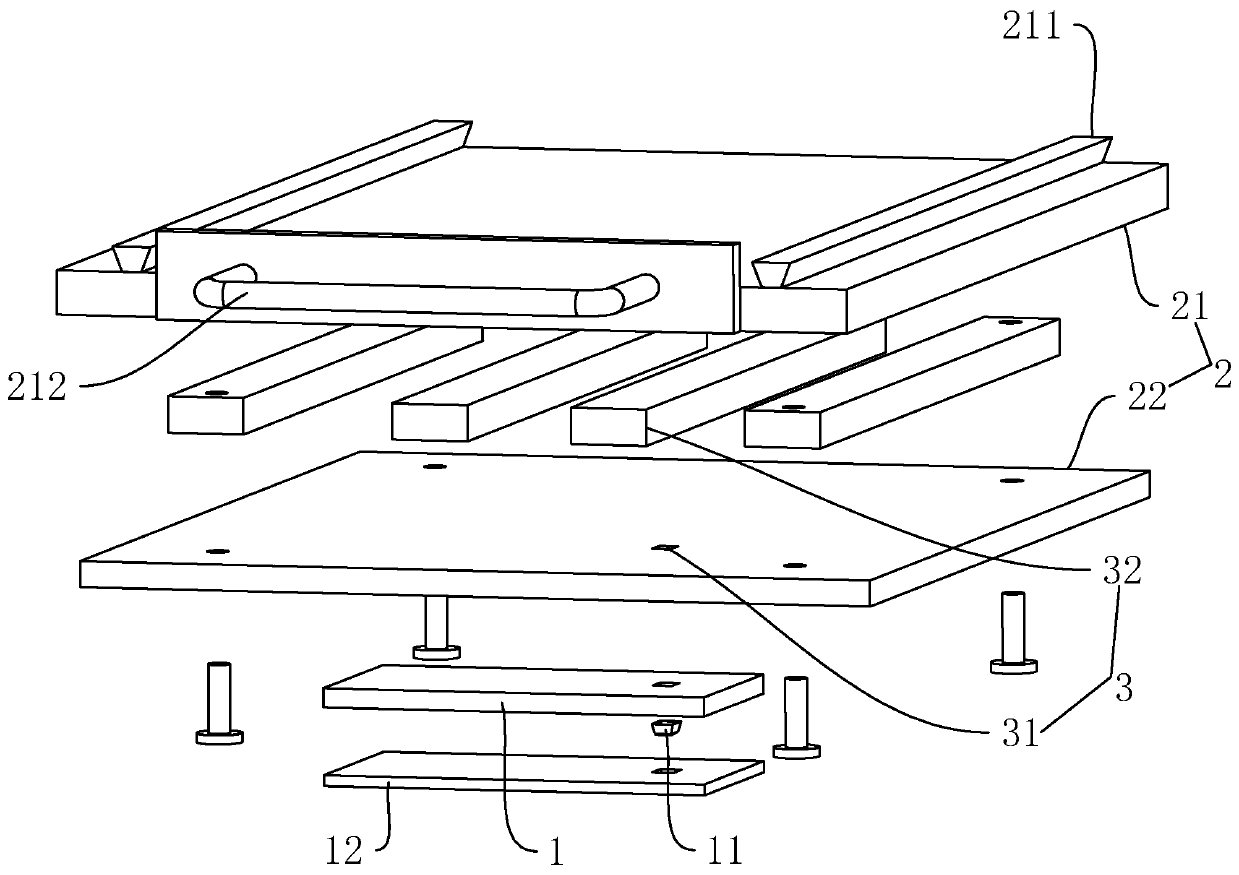

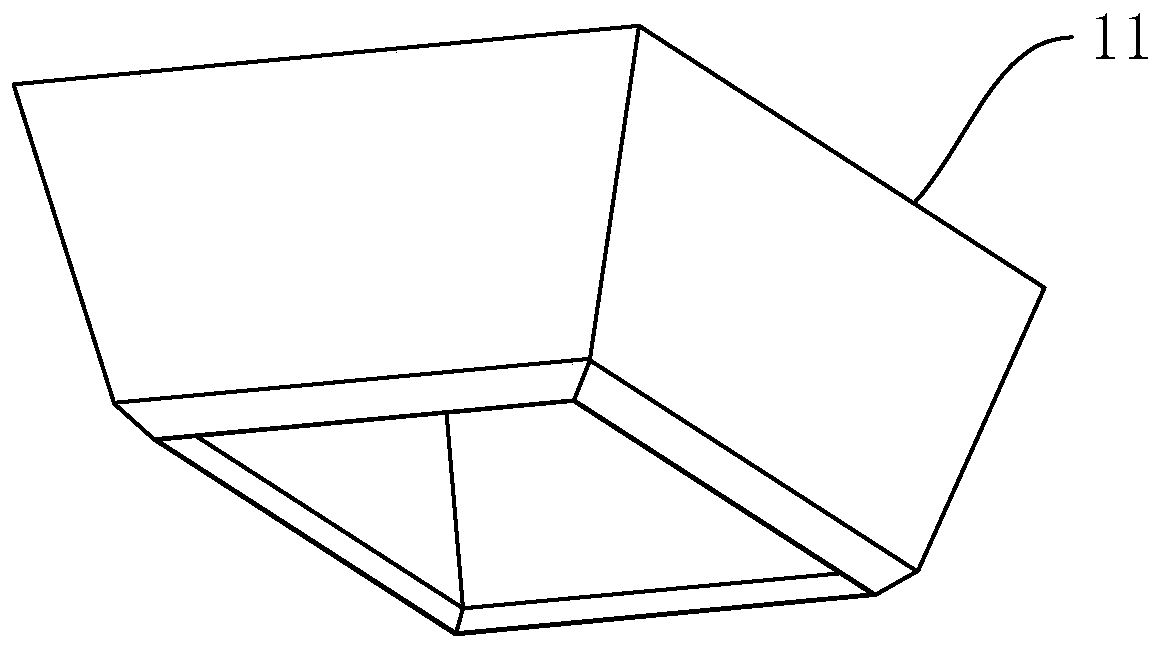

[0035] Embodiment one, with reference to figure 1 and figure 2 , is a die-cutting mechanism disclosed in the present invention, which can carry the remaining material generated by cutting from the perforation while cutting and forming a perforation, without the need for subsequent manual tearing of the remaining material; The die-cutting mechanism includes a mounting plate 1, which is made of stainless steel. In this embodiment, the mounting plate 1 is in the shape of a cuboid. In other embodiments, the mounting plate 1 can also be in the shape of a disc; A die cutter 11 is provided, and the die cutter 11 is made of stainless steel. In this embodiment, the die cutter 11 is in the shape of a square ring, and in other embodiments it can also be in the shape of a ring or a waist ring. , the shape of the die-cutter 11 should be selected according to the shape actually needed for the perforation on the label; the cutting edge of the die-cutter 11 is arranged at the port at one en...

Embodiment 2

[0043] Embodiment two, refer to Figure 4 and Figure 5 , a die-cutting machine, comprising: upper die base 4, lower die base 5 and drive rod 6, upper die base 4 and lower die base 5 are in the shape of a cuboid and are made of carbon steel, upper die base 4 and lower die base The seat 5 is set up and down oppositely; the lower mold seat 5 is fixed on a workbench by bolts; the drive rod 6 is cylindrical, and in this embodiment, the drive rod 6 is provided with four vertically parallel to each other, and the four drive rods 6 Respectively vertically fixed on the four corners of the upper mold base 4 near the surface of the lower mold base 5, and the end of the drive rod 6 away from the upper mold base 4 passes through the lower mold base 5 and is inserted below the workbench. The lower mold base 5 is slidingly connected, and the driving rod 6 is fixedly connected with the upper mold base 4 by bolts; the way of driving the driving rod 6 to move up and down can be driven up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com