Teaching machining type intelligent manufacturing integration system

A technology of intelligent manufacturing and integrated systems, applied in the direction of chemical instruments and methods, cleaning methods and utensils, pollution prevention methods, etc., can solve the problems of reducing the service life of teaching devices, increasing cost investment, inconvenient use, etc., to achieve reduction Cost input, reduce the use of manpower, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means realized by the present invention, the creative features, the purpose and the effect achieved are easy to understand, the present invention will be further elaborated below in conjunction with specific embodiments.

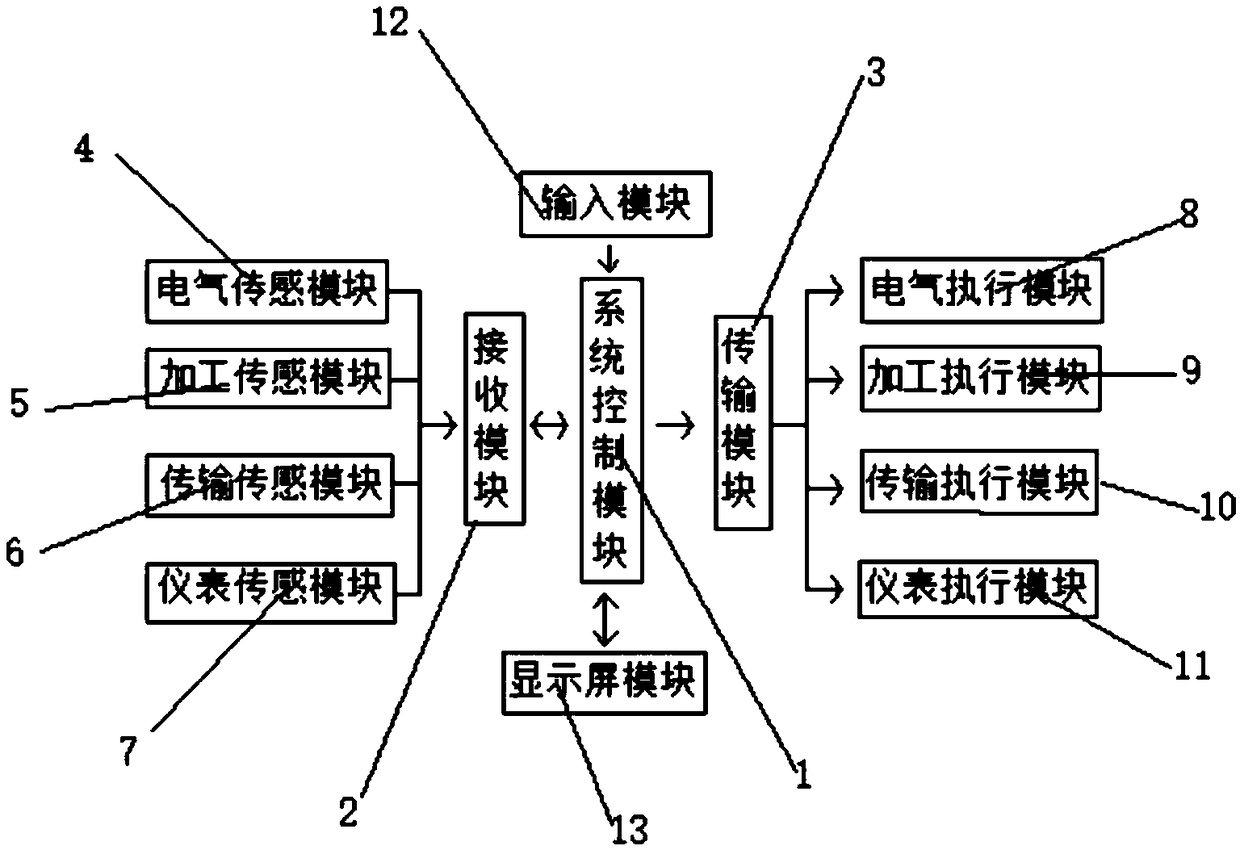

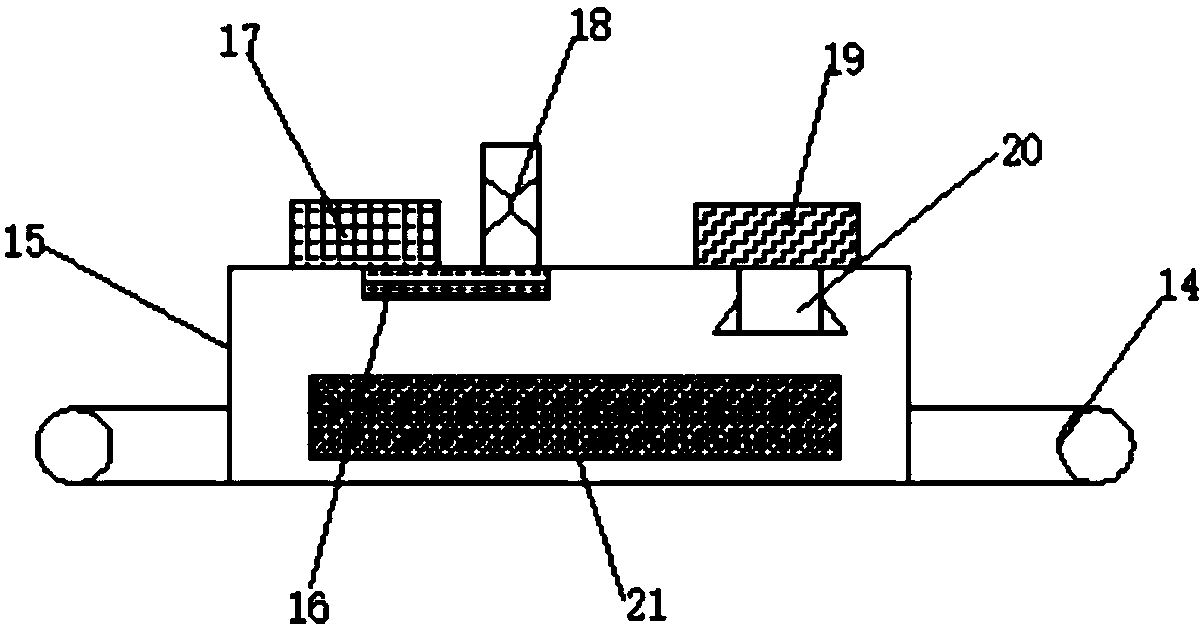

[0017] see Figure 1-Figure 2 , a teaching and processing type intelligent manufacturing integrated system, including a system control module 1, a transmission execution module 10, an alarm device 16, a buzzer 17 and a fan 19, the system control module 1 and the receiving module 2 are connected to each other, the system The control module 1 is connected to the display module 13, the system control module 1 is connected to the transmission module 3, and the transmission module 3 is connected to the electrical execution module 8, the processing execution module 9, the transmission execution module 10 and the instrument execution module 11, The transmission execution module 10 is provided with a casing 15, and the inside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com