Foam board cutting equipment

A cutting equipment, foam board technology, applied in the direction of removing smoke and dust, recycling technology, metal processing, etc., can solve the problem of not being able to remove toxic gas, health effects, foam board burns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

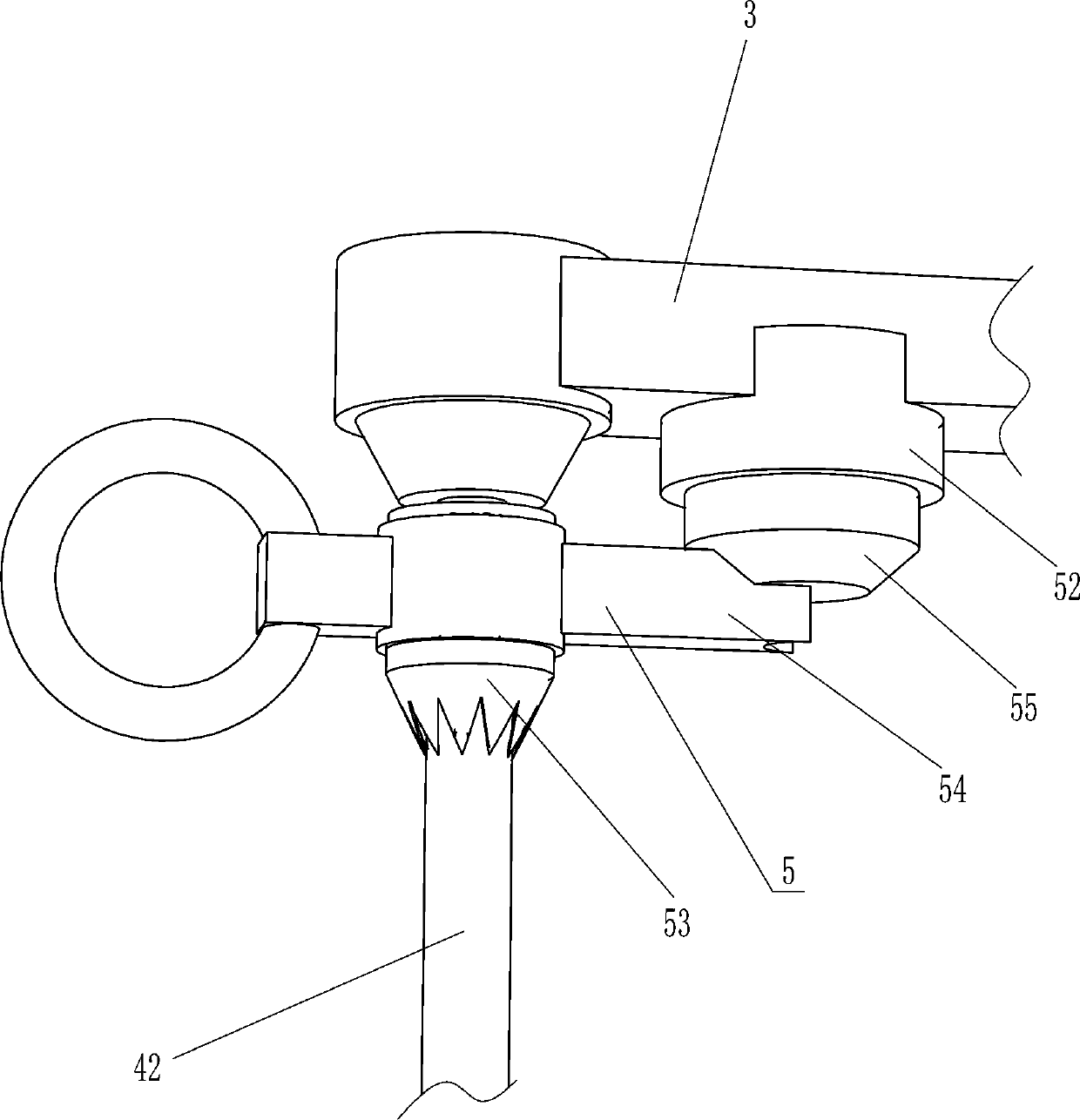

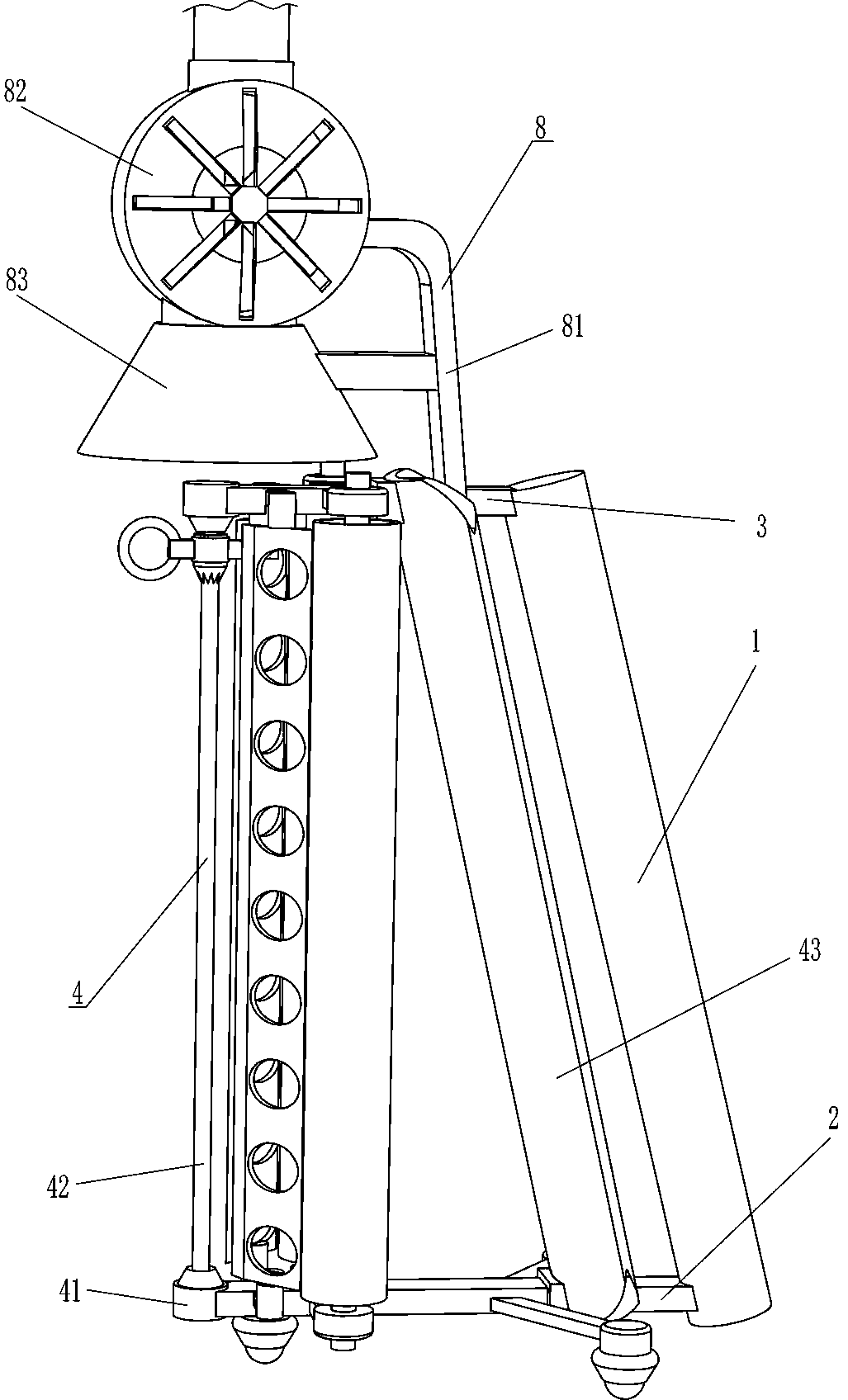

[0023] see Figure 1-Figure 3 , a foam board cutting equipment, including a handle 1, a mounting rod 2, a fixed rod 3, a melting and cutting mechanism 4 and a cleaning mechanism 5, the lower part of the left side of the handle 1 is fixedly connected with the installation rod 2, and the upper part of the left side of the handle 1 is fixed A fixed rod 3 is connected, a melting and cutting mechanism 4 is arranged between the fixing rod 3 and the installation rod 2 , and a cleaning mechanism 5 is arranged between the fixing rod 3 and the melting and cutting mechanism 4 .

[0024] The melting and cutting mechanism 4 includes a heat insulating block 41, a heating wire 42 and a protective plate 43, and a protective plate 43 is embedded between the right side of the top of the mounting rod 2 and the right part of the fixed rod 3, and the left end of the fixed rod 3 is connected to the mounting rod 2 A thermal insulation block 41 is fixedly connected to the left end, and a heating wire...

Embodiment 2

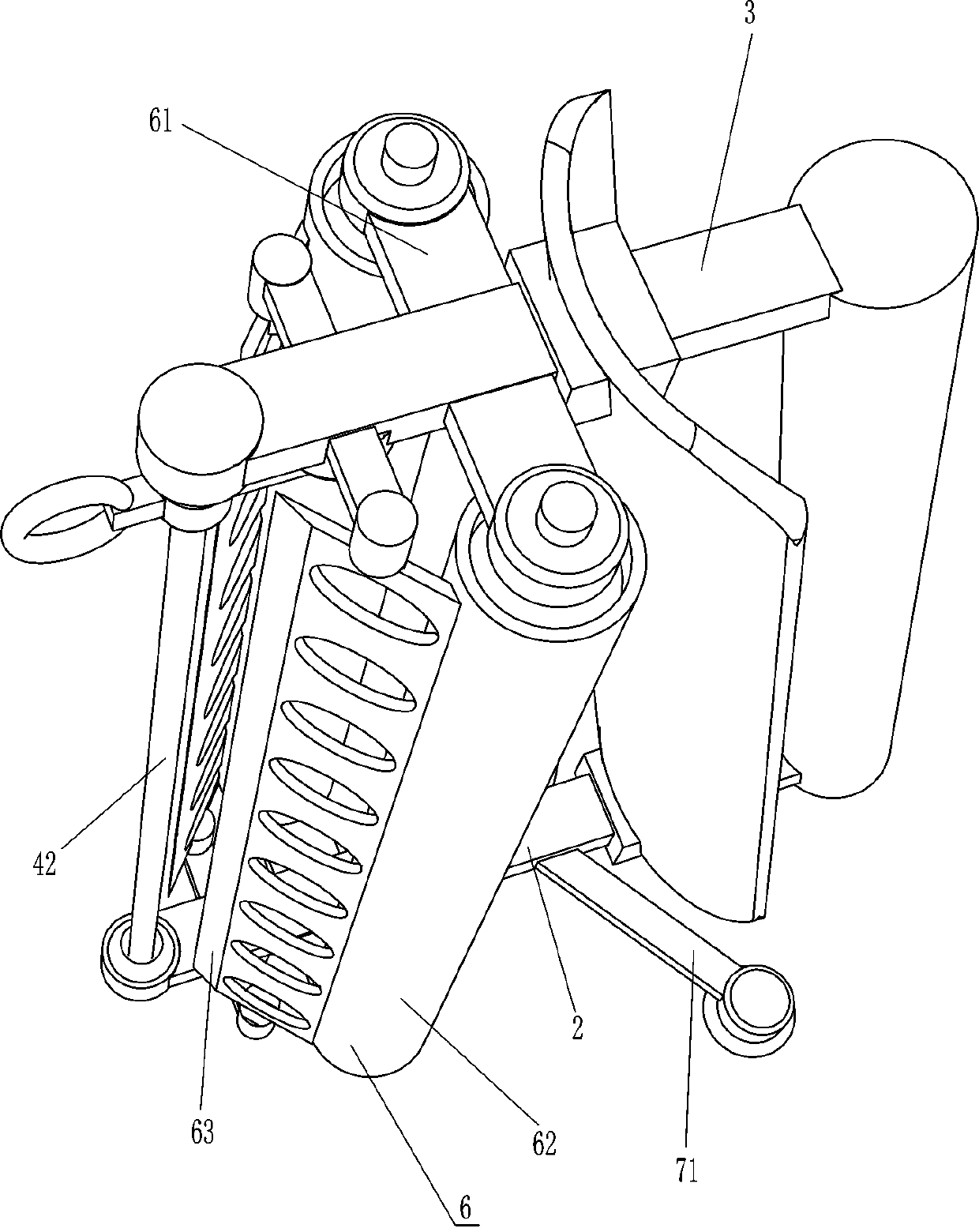

[0030] see figure 1 , Figure 4 and Figure 5Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, a flaring mechanism 6 is also included. The flaring mechanism 6 includes a fixed frame 61, a roller 62 and a guide plate 63, and the left side of the front and rear sides of the fixed rod 3 The left part of the front and rear sides of the installation rod 2 is fixedly connected with a fixed frame 61, and the roller 62 is rotatably connected between the fixed frame 61 of the upper and lower sides of the front and the fixed frame 61 of the upper and lower sides of the rear, and the front side of the fixed rod 3 A guide plate 63 is fixedly connected between the left side and the left side of the front side of the installation rod 2 , and a guide plate 63 is also fixedly connected between the left side of the rear side of the fixed rod 3 and the left side of the rear side of the installation rod 2 .

[0031] Also comprise auxiliary mobile me...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap