Taper guiding mechanism for injection mold

A guiding mechanism and injection mold technology, applied in the field of injection molds, can solve the problems of product quality such as gaps left in the air and drums, rough taper processing, sticky and white scraps, etc., to improve the consumption of taper manual adjustment and facilitate taper pressure And angular distance, the effect of pass rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

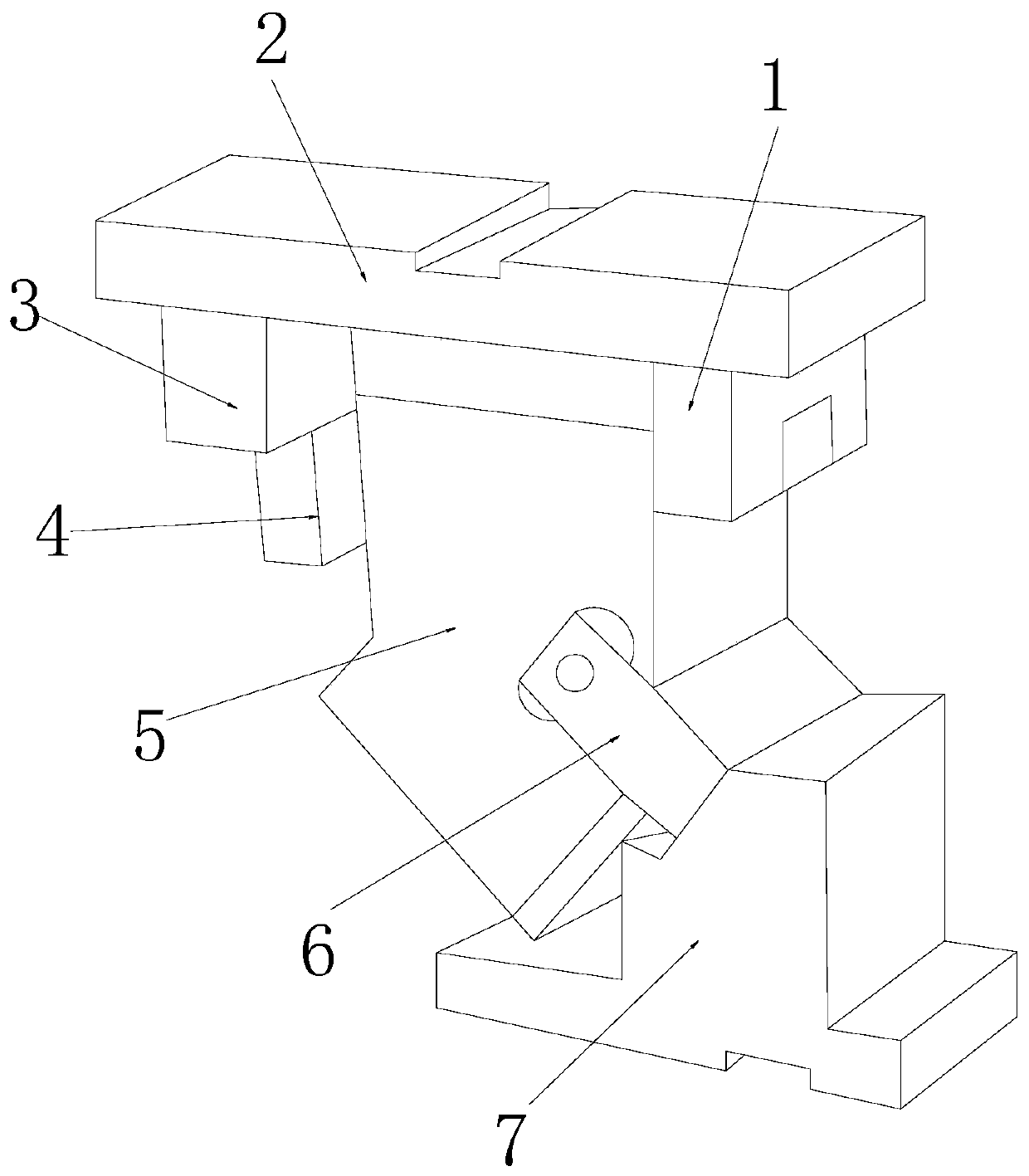

[0033] see Figure 1-Figure 6 , the present invention provides a taper guide mechanism for an injection mold, the structure of which includes: a bayonet plug block 1, a parting surface support plate 2, a trachea slot 3, an insert plate 4, a card angle taper frame 5, and a taper angle guide wheel Groove 6, formwork groove column block 7, described cone angle guide wheel groove 6 and card angle taper frame 5 are fastened together and are on the same vertical plane, and described cone angle guide wheel groove 6 is inserted in formwork groove column block 7, the trachea slot 3 is nested on the top of the insert plate 4 and is on the same vertical plane, and the trachea slot 3 and the bayonet socket block 1 are respectively inserted into the parting surface support The left and right lower corners of the plate 2 are parallel to each other, the card angle taper frame 5 is close to the bottom surface of the bayonet plug block 1 and is on the same vertical plane, and the cone angle gu...

Embodiment 2

[0040] see Figure 1-Figure 6 , the present invention provides an injection mold taper guide mechanism, which is the same as in Embodiment 1 in other respects, except that:

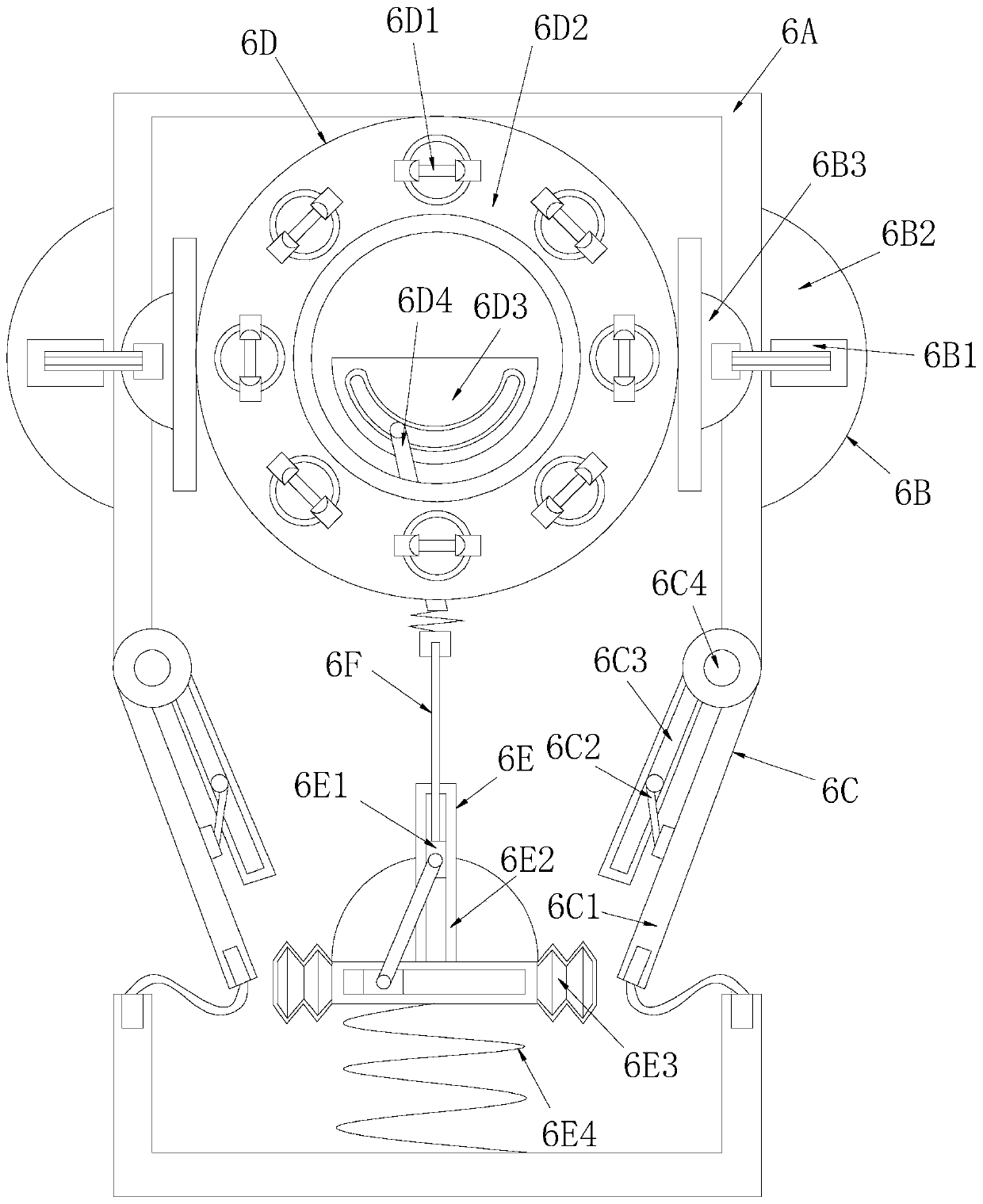

[0041] see figure 2 , the lifting and pushing bracket seat 6E is composed of a lifting column block 6E1, a cross track seat 6E2, a louver support groove 6E3, and a torsion spring wire 6E4. The lifting column block 6E1 and the cross track seat 6E2 adopt a clearance fit, and the The cross track seat 6E2 is mechanically connected with the torsion spring wire 6E4, and the said louver support groove 6E3 is provided with two and respectively installed on the left and right sides of the cross track seat 6E2, and the left and right ends of the cross track seat 6E2 are limited by the louver support groove 6E3. The elastic pressure cone angle slope forms an overall horizontal and vertical inner frame top support effect, ensuring the stability of the limit rotation and the lifting angle of the plate.

[0042] see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com