Transverse unflatness control method for high-strength aluminum alloy plate

A technology of an aluminum alloy sheet and a control method, which is applied in the field of lateral unevenness control of the aluminum alloy sheet, can solve the problems such as the unattainable flatness of the aluminum alloy sheet, reduce deformation, meet the processing and manufacturing requirements of parts, and reduce cooling deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

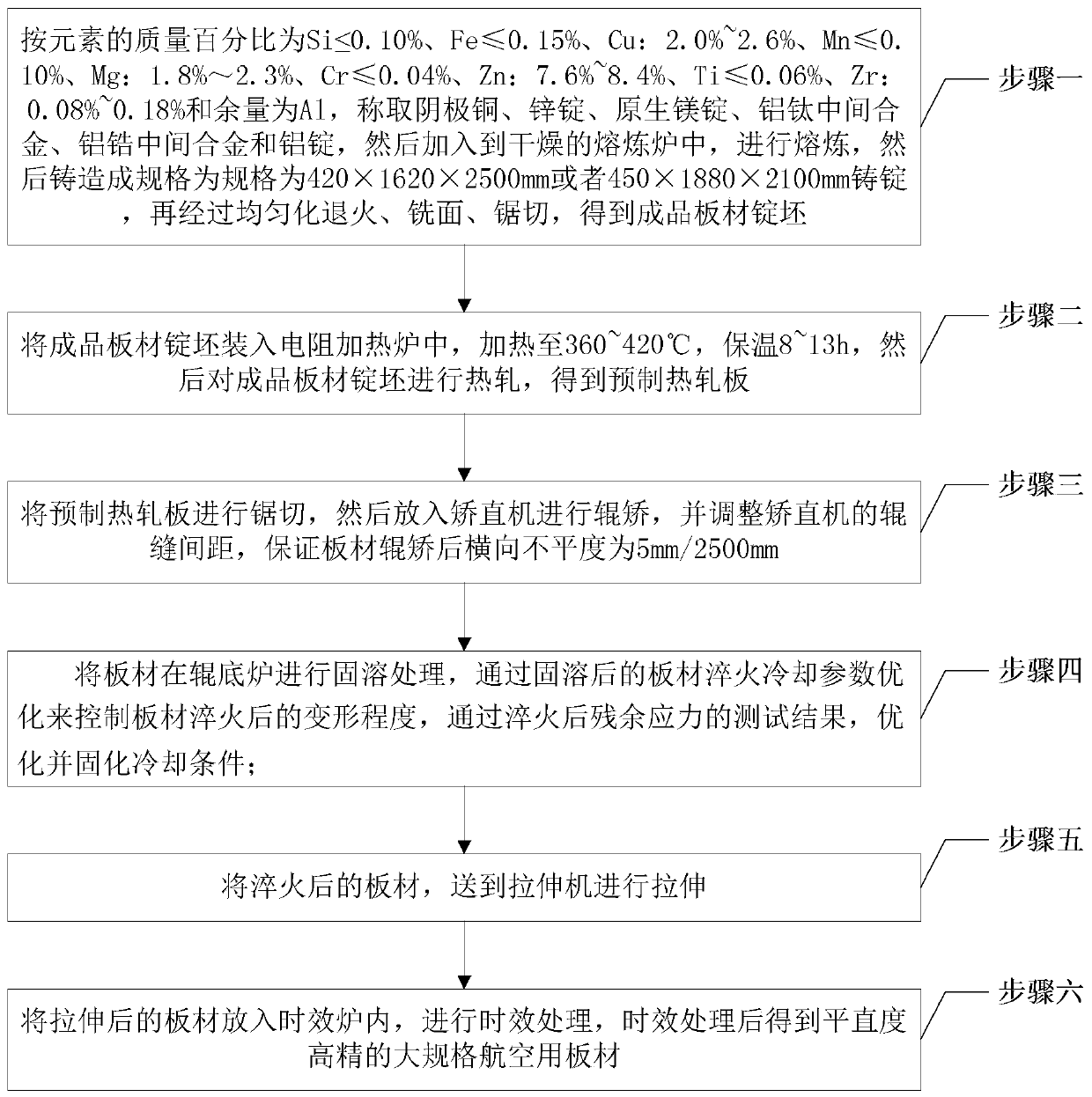

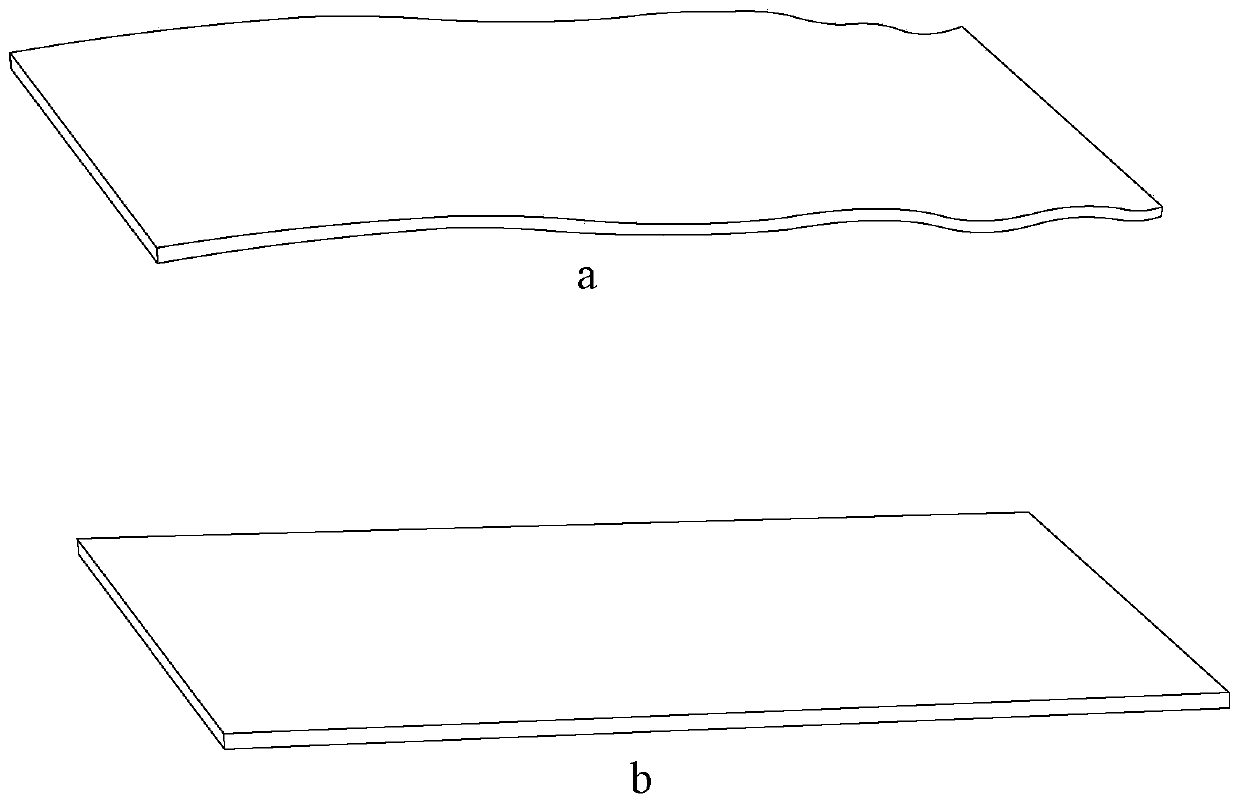

[0014] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, a method for controlling transverse roughness of a high-strength aluminum alloy sheet described in this embodiment is characterized in that the method for controlling transverse roughness includes the following steps:

[0015] Step 1. Si≤0.10%, Fe≤0.15%, Cu: 2.0%-2.6%, Mn≤0.10%, Mg: 1.8%-2.3%, Cr≤0.04%, Zn: 7.6%- 8.4%, Ti≤0.06%, Zr: 0.08%~0.18% and the balance is Al, weigh the cathode copper, zinc ingot, primary magnesium ingot, aluminum-titanium master alloy, aluminum-zirconium master alloy and aluminum ingot, and then add it to the dry Melted in a melting furnace, then cast into ingots with specifications of 420×1320×2000mm, 420×1620×2500mm or 450×1880×2100mm, and then homogenized annealing, face milling and sawing to obtain finished plate ingots ;

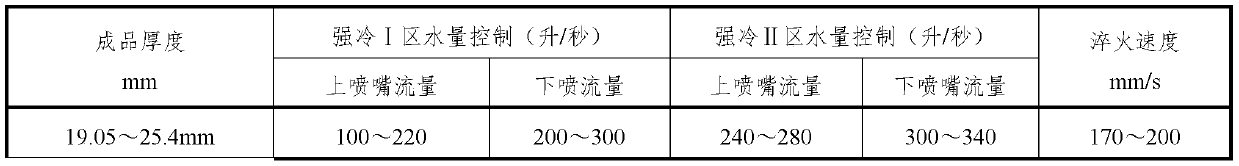

[0016] Step 2. Put the finished plate ingot obtained in step 1 into a resistance heating furnace, heat it to 360-420° C., ...

specific Embodiment approach 2

[0023] Specific embodiment 2: This embodiment is to further limit the method for controlling the transverse roughness of a high-strength aluminum alloy sheet described in specific embodiment 1. In this embodiment, in step 2, when the finished plate ingot is hot-rolled , the direction of the bending force is positive, the size is 2700 ~ 3000KN.

[0024] In this embodiment, by adjusting the direction of the bending force to be positive and the magnitude of the force to be 2700-3000KN, the subtle thickness difference in the cross-section of the plate is finely controlled to ensure that the thermal deformation of the entire transverse end surface of the plate is uniform, and to reduce the temperature of the hot-rolled plate. deformation after cooling.

specific Embodiment approach 3

[0025] Specific embodiment 3: This embodiment is to further limit the method for controlling the transverse roughness of a high-strength aluminum alloy sheet described in specific embodiment 1. In this embodiment, in step 3, the set value of the displacement of a roll on the straightening machine The range is: 17.0~25.0mm; the displacement setting range of the second roller on the straightening machine is: 10.0~23.0mm; the displacement setting value range of the three rollers on the straightening machine is: 10.0~20.5mm; the displacement setting of the four rollers on the straightening machine The value range is: 13.5~16.5mm; the range of the displacement setting value of the five rollers on the straightening machine is: 13.5~16.5mm; the setting value range of the displacement setting value of the six rollers on the straightening machine is: 17.5~25.5mm.

[0026] In this embodiment, the displacement setting range of the upper roll of the straightening machine for hot-rolled pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com