Frame of sewing machine

A sewing machine and frame technology, which is applied in the field of sewing machine frames, can solve the problems of inconvenient movement, difficulty in placing the sewing machine stably, and small contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

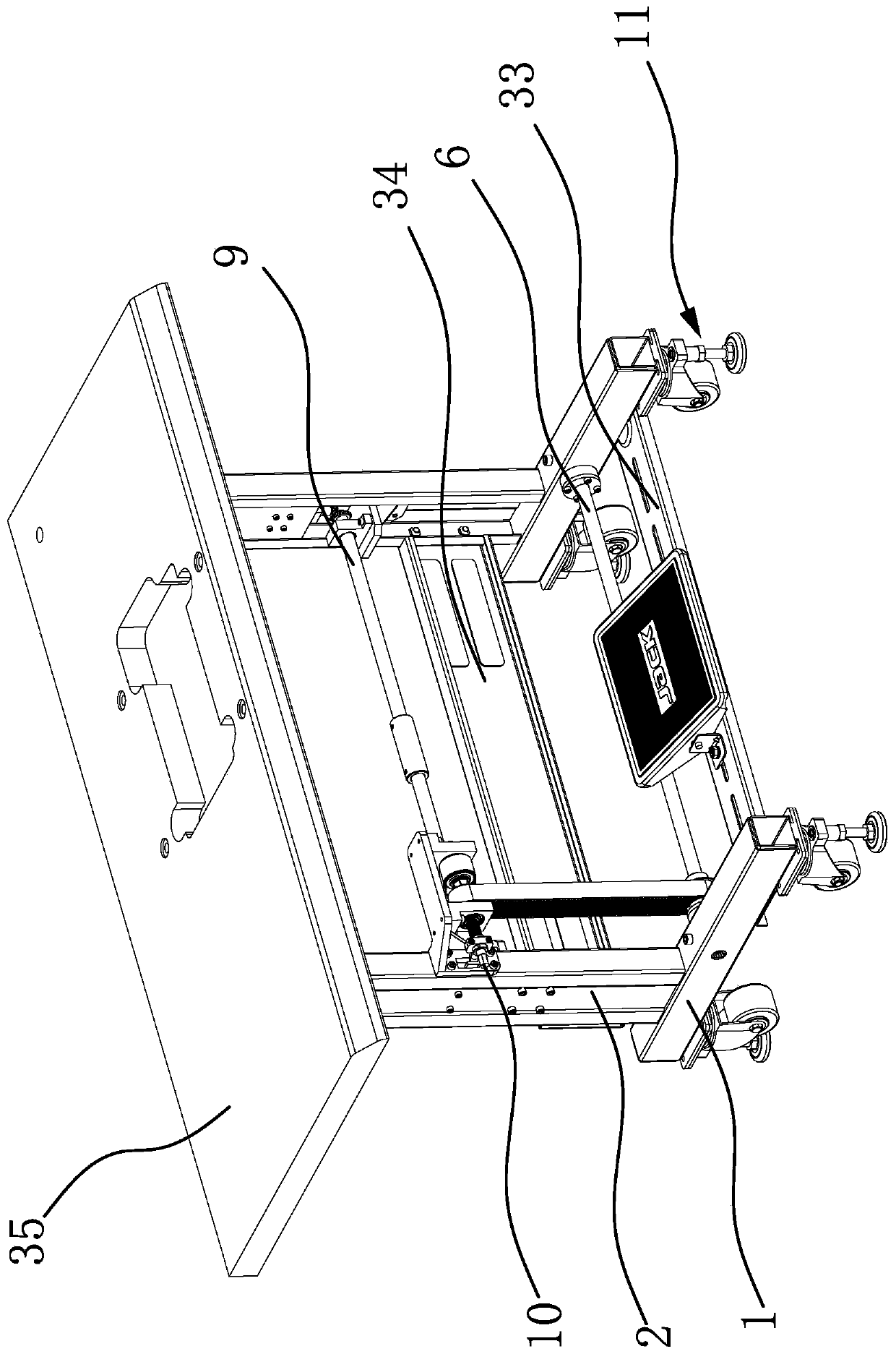

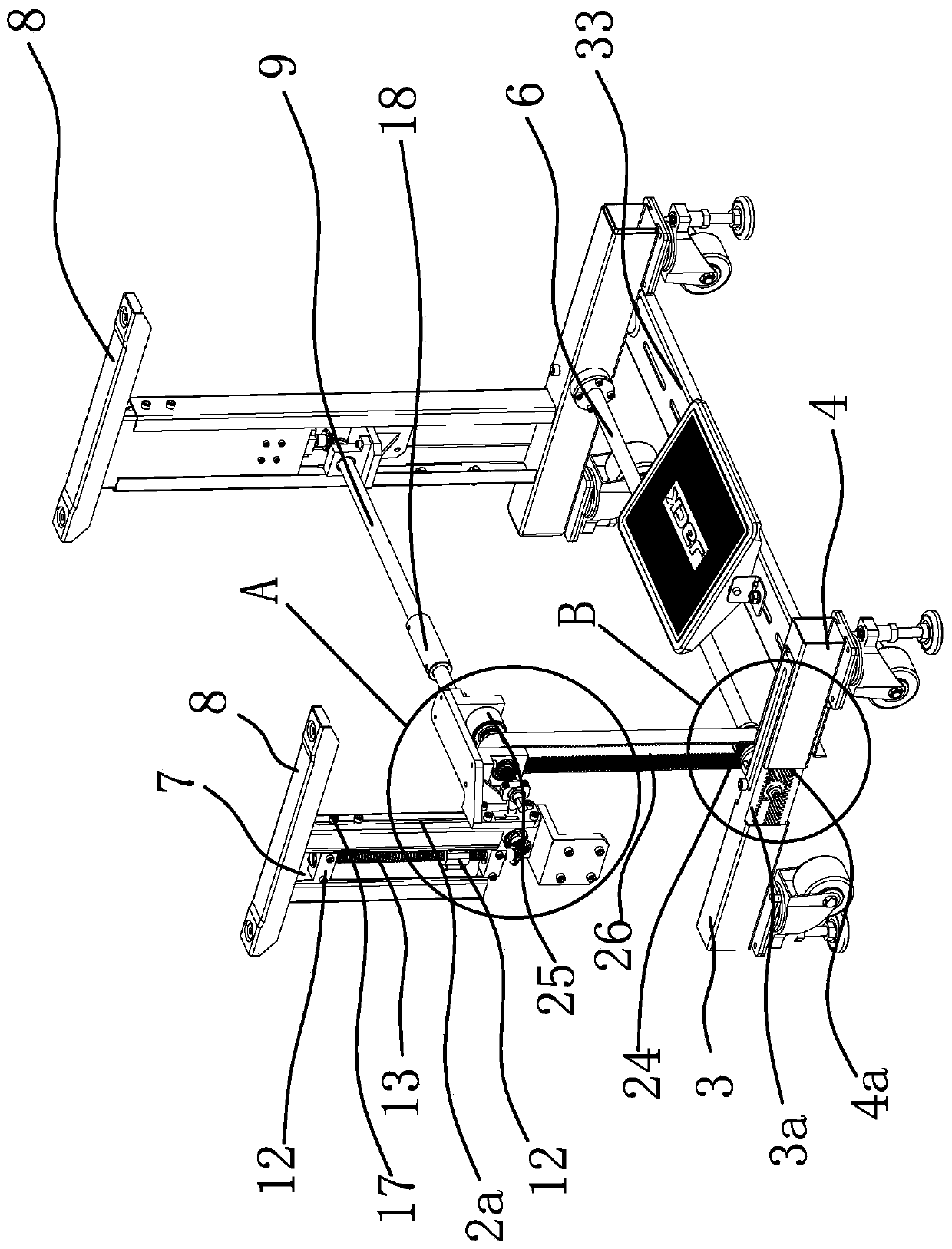

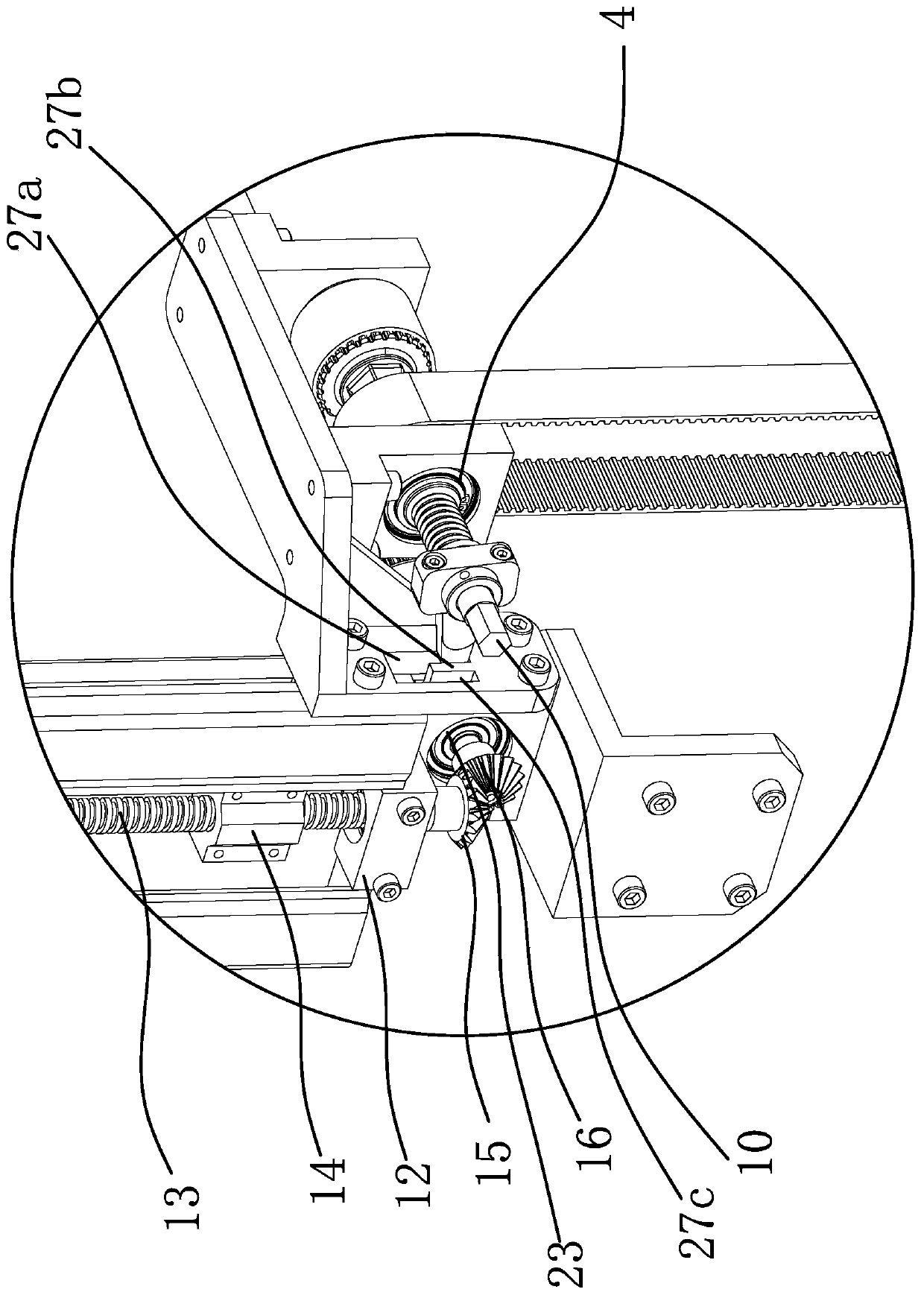

[0039] Such as Figure 1 to Figure 7 As shown, the frame of the sewing machine includes two tubular bases 1 vertically spaced apart, each base 1 is vertically fixed with a column 2, and the two ends of each base 1 are respectively movably inserted with an upper support tube 3 and Lower support tube 4, the lower side of the lower support tube 4 has a lower rack 4a extending towards the inside of the base 1, and the upper side of the upper support tube 3 has an upper rack 3a extending towards the inside of the base 1; the upper rack 3a and the lower teeth The bar 4a is arranged oppositely and is provided with the meshing gear 5 that can simultaneously drive the upper rack 3a and the lower rack 4a to move longitudinally between the two, and the lower transmission shaft 6 is connected on the meshing gear 5; The upper end of the lifting pillar 7 is provided with a supporting plate 8, and the lower part of the lifting pillar 7 is provided with an upper transmission shaft 9 that can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com