Waste utility pole removal machine

A technology for removal of electric poles, which is applied in the field of waste electric pole removal machines, can solve the problems of affecting the access of surrounding vehicles, exposed steel bars of electric poles, potential safety hazards, etc., and achieves rapid and efficient movement, increased mobility, and easy transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

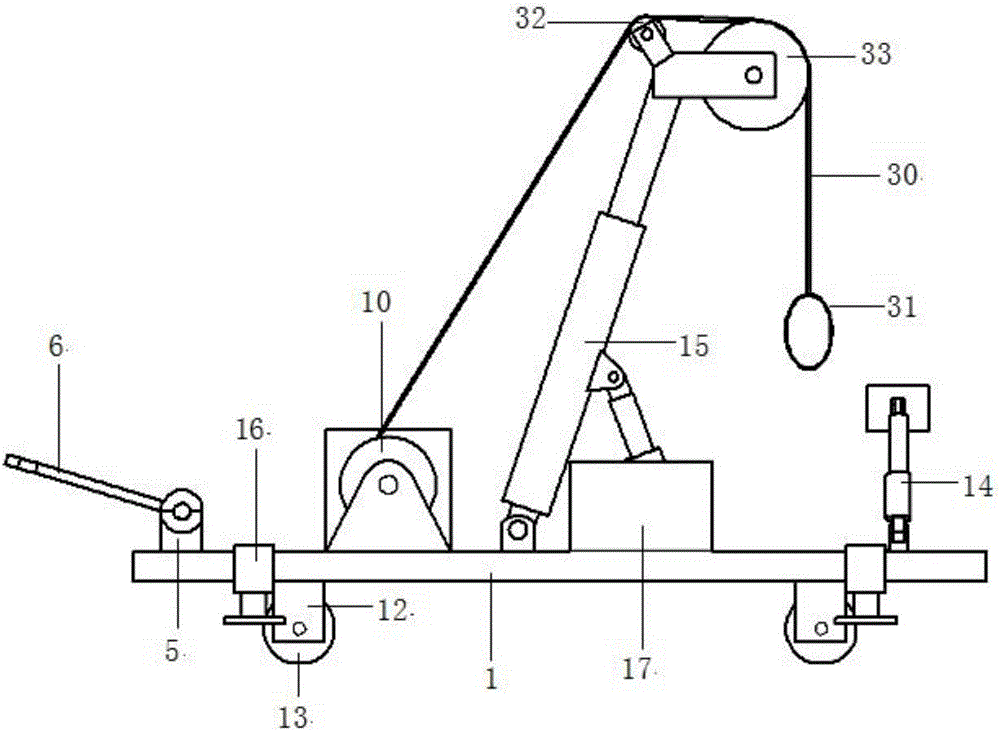

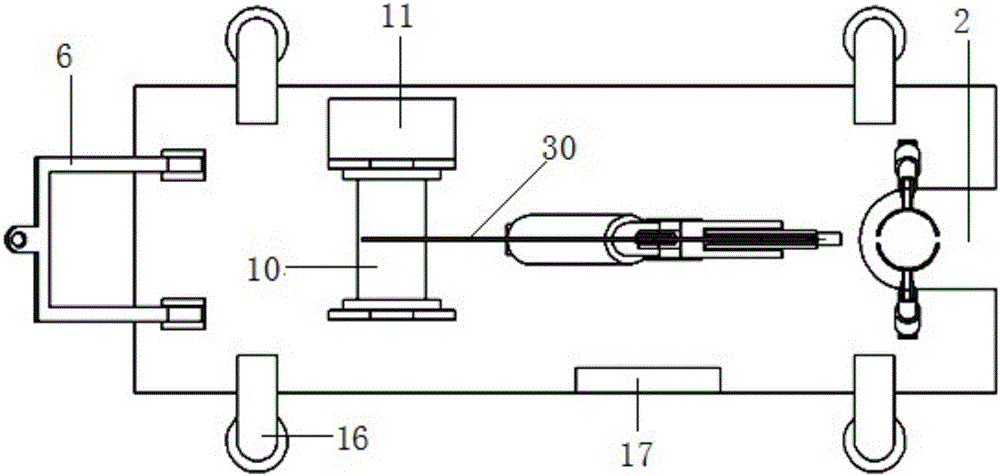

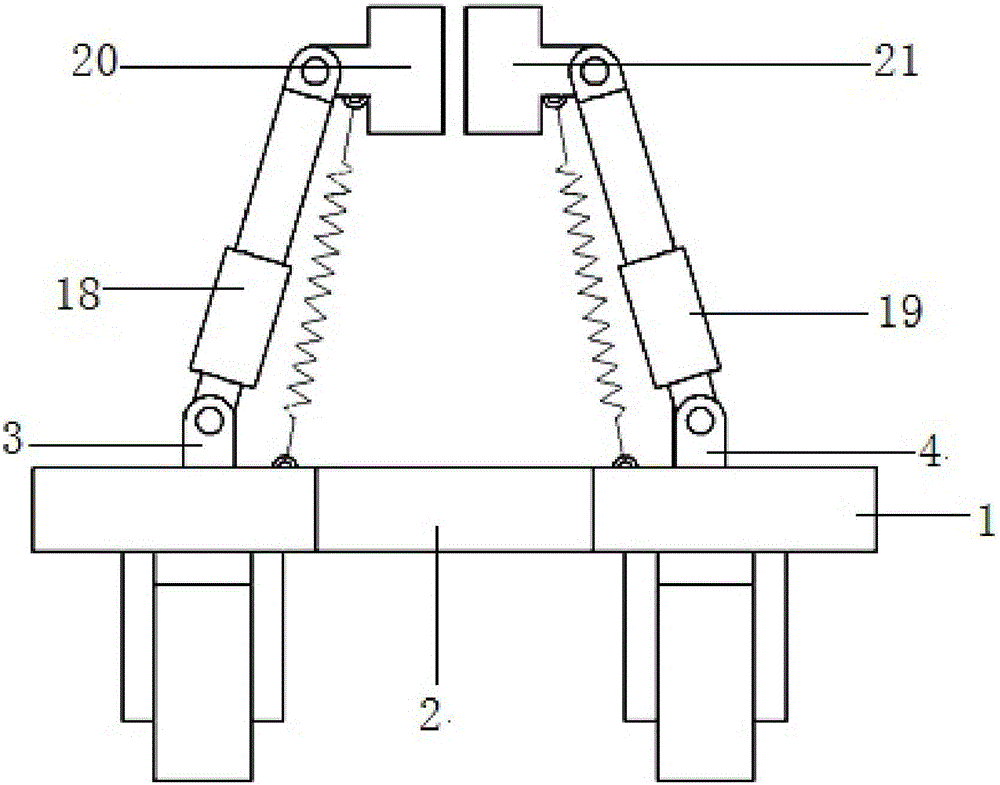

[0018] Specific implementation method: combined Figure 1-6 As shown, including base plate 1, a U-shaped groove 2 is opened on one side of the length direction of the base plate 1; A base 3 and B base 4 are symmetrically installed on both sides of the upper surface of the base plate 1 U-shaped groove 2; A base 3, B base 4 A pull-up device 14 is connected through a pin shaft; a C base 5 is installed on the side opposite to the U-shaped groove 2 on the upper surface of the base plate 1; the C base 5 is connected with a traction frame 6 through a pin shaft; the U-shaped groove 2 on the upper surface of the base plate 1 D base 7, E base 8, F base 9 are installed between C base 5; D base 7 is connected with reel 10 through pin shaft; D base 7 side is installed with motor 11 on the bottom plate 1 upper surface width direction; The machine shaft of 11 is splinedly connected with reel 10; E base 8, F base 9 are connected with hoisting device 15 by pin shaft; Base plate 1 lower surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com