Road surface drainage well self-regulated-controlled for cleaning

A self-regulating, drainage well technology, applied to drainage structures, waterway systems, water supply devices, etc., can solve the problems of poor drainage and difficult cleaning of drainage wells, and achieve the effects of preventing injuries, increasing drainage, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

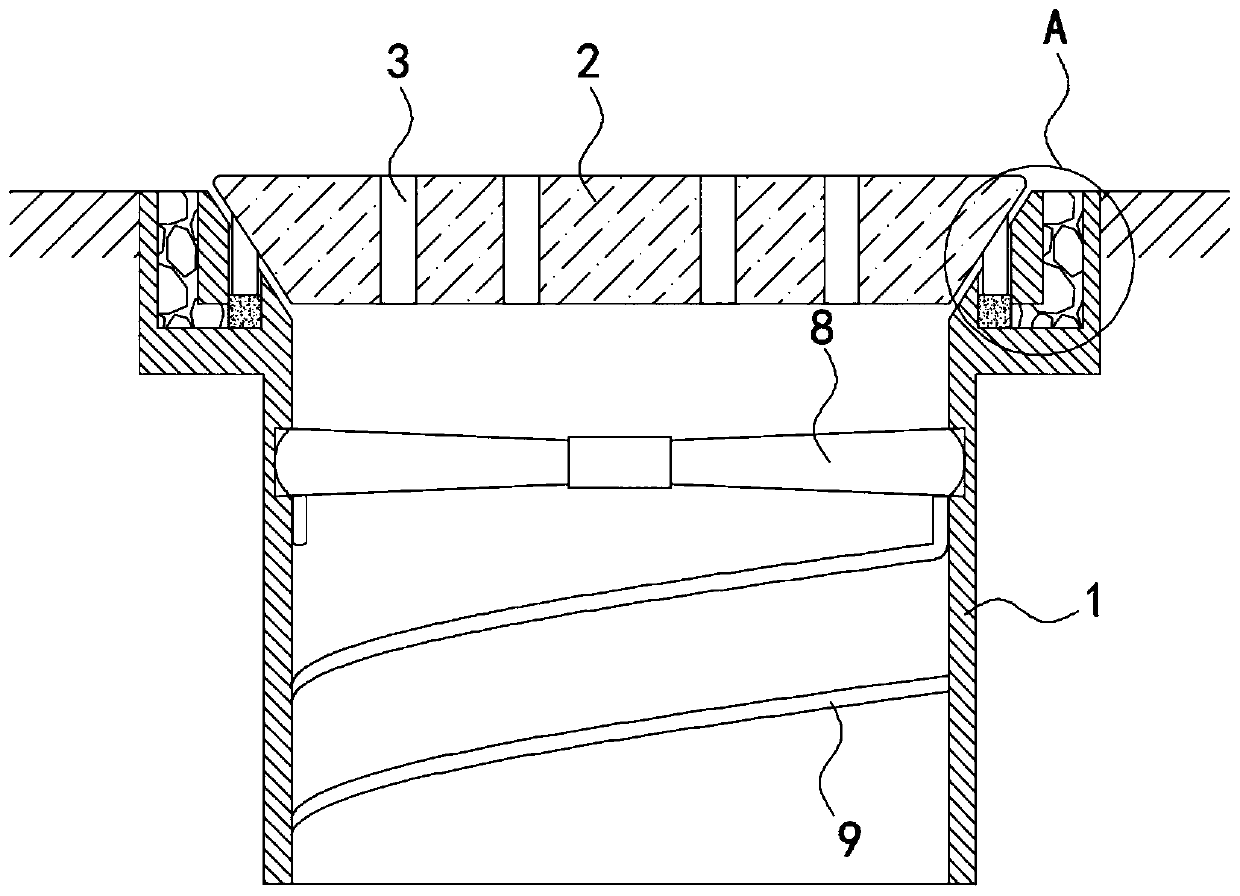

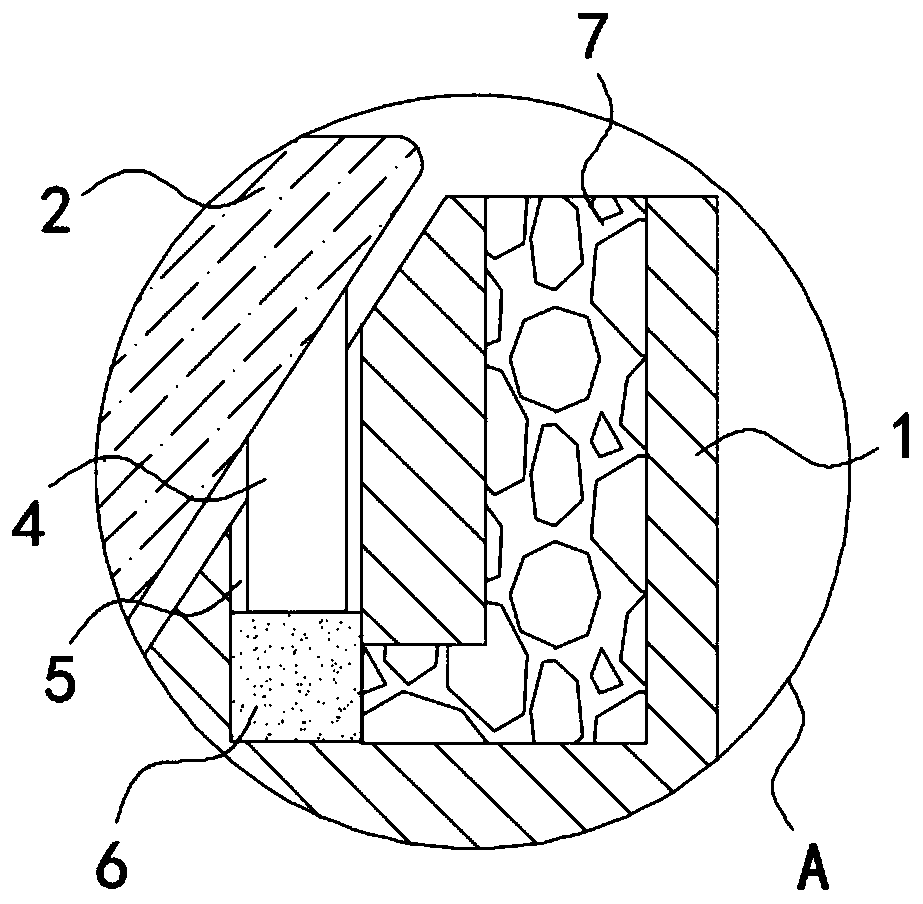

[0022] Such as Figure 1-4 As shown, a self-regulating and clean road drainage well includes a well body 1 and a well cover 2 arranged above the well body 1. The surface of the well cover 2 is provided with a plurality of equally spaced strip drainage holes 3, and the well cover 2 is inverted The upper opening of the well body 1 is in the shape of a truncated cone, and it is arranged in a horn-like shape and is attached to the 2 peripheral side walls of the well cover. A plurality of support bars 4 arranged in an annular array are fixedly installed on the peripheral side walls of the well cover 2, and the upper end of the well body 1 is provided There are a plurality of strip grooves 5 matching the support bar 4, the lower end of the support bar 4 extends into the strip groove 5, the bottom of the strip groove 5 is provided with a water-absorbing expansion block 6, and the upper surface of the well body 1 is provided with a water-permeable layer 7. The lower end of the water-pe...

Embodiment 2

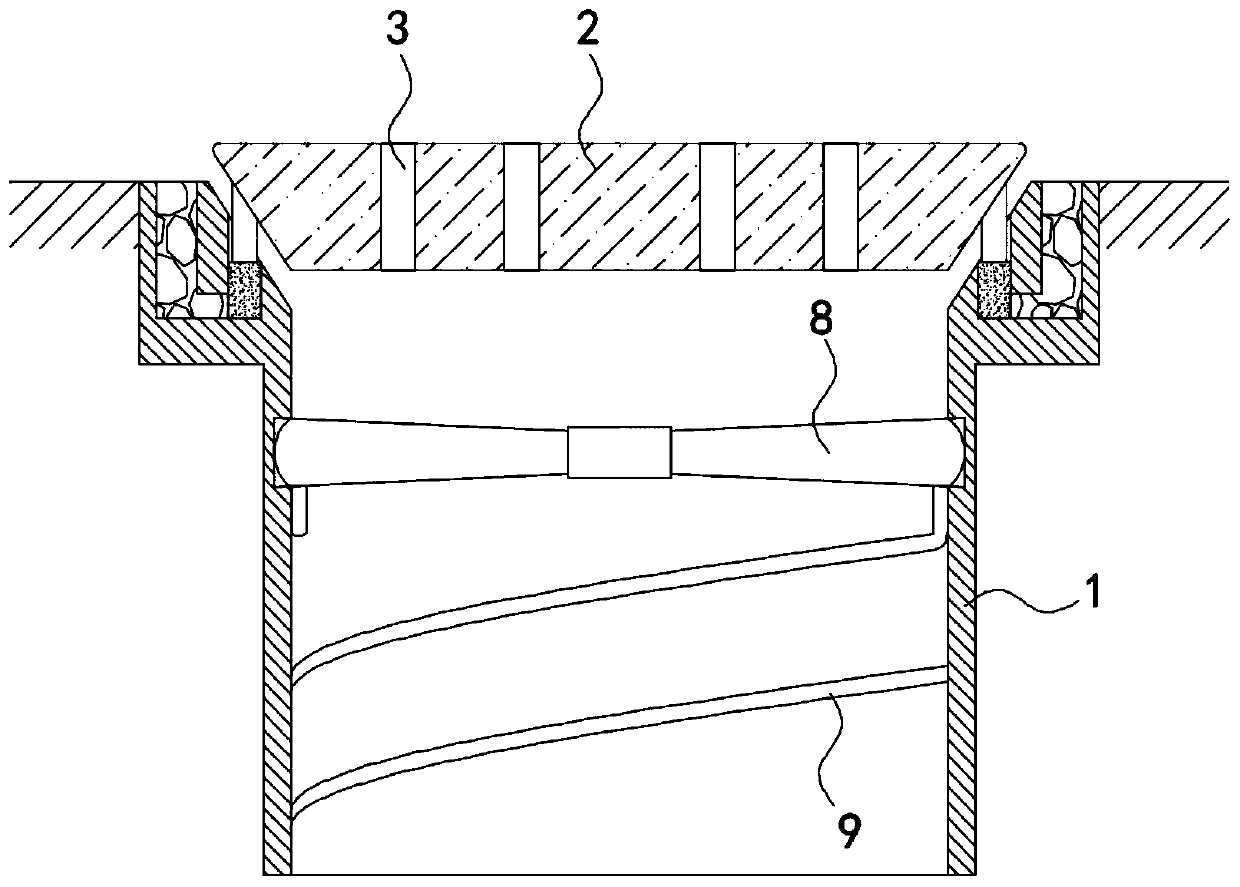

[0030] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the impeller 8 includes a gear 10 and fan blades 11 fixedly mounted on both sides of the gear 10. The two fan blades 11 are separated from each other on the side of the shaft 1 The wall is rotatably connected, and the bottom surface of the manhole cover 2 is rotatably connected with a vertical rack 12 which meshes with the gear 10.

[0031] In this embodiment, when the road area has a large amount of water, when the support bar 4 pushes the manhole cover 2 upward, it drives the rack 12 to move upward, and the gear meshed with it rotates 90°, that is, the fan blade 11 turns 90° along its axis. °, at this time, under the impact of the water flow, the force direction of the fan blade 11 changes, the impeller 8 rotates in the reverse direction, and then drives the scrubbing strip 9 to rotate in the reverse direction. This structure allows the scrubbing strip 9 to reciprocate in the well ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com