Mining rock drill

A rock drill and mining technology, applied in the field of mining machinery, can solve problems affecting workers' operating vision and operating errors, and achieve the effect of ensuring the operating vision, ensuring operation, and reducing drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

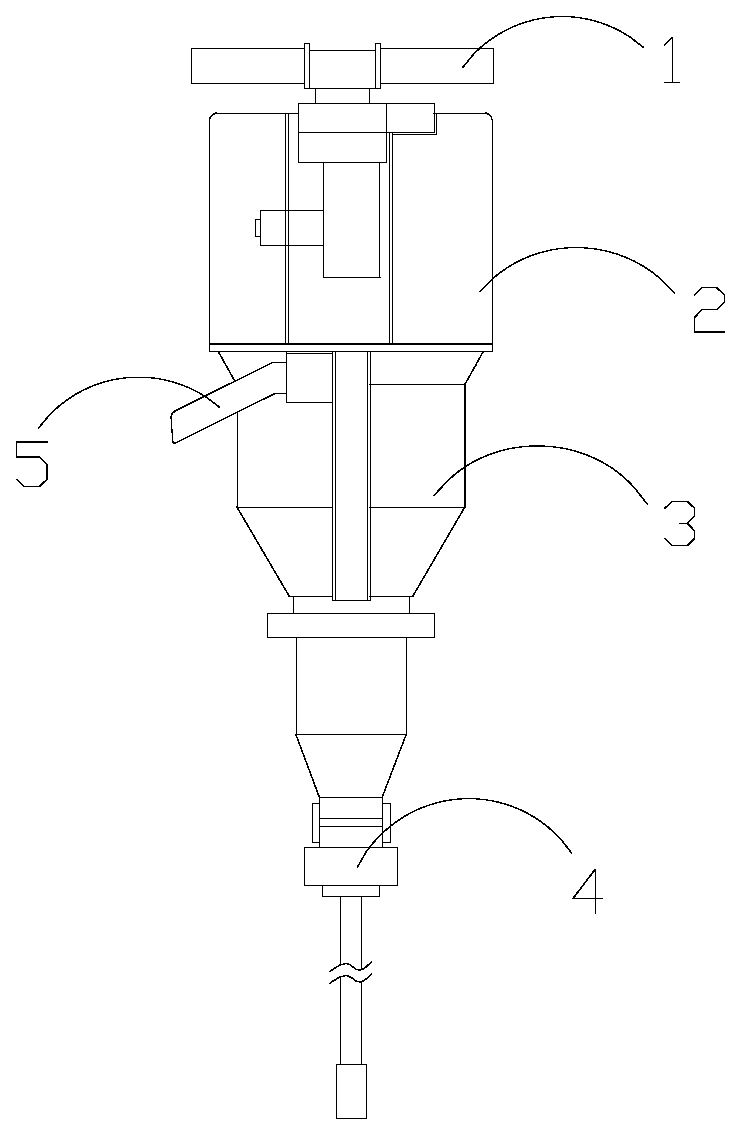

[0030] Example 1: Please refer to Figure 1-Figure 6 , the specific embodiments of the present invention are as follows:

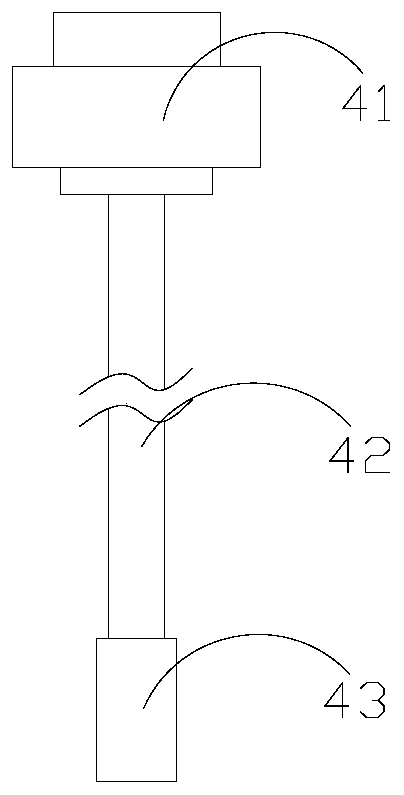

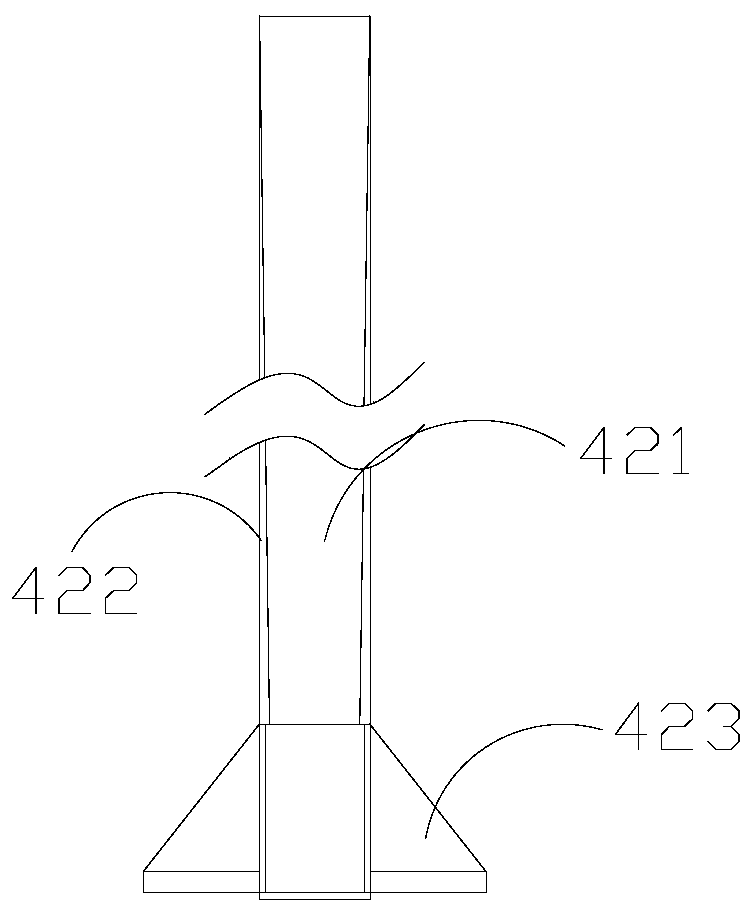

[0031] Its structure includes a handle 1, a machine head 2, a drive box 3, a rock drilling mechanism 4, and a side handle 5. The handle 1 is horizontally installed on the upper end of the machine head 2 and is mechanically connected. The drive box 3 is vertically installed on the The lower end of the machine head 2 is engaged with each other, the rock drilling mechanism 4 is vertically fixed on the lower end of the driving box 3 and is located on the same center line, the side handle 5 is installed on the side end of the driving box 3 and is fixedly connected; the rock drilling mechanism 4 includes a fixing seat 41, a steel brazing structure 42, and an impact head 43. The steel brazing structure 42 is vertically embedded and installed inside the fixing seat 41 and is mechanically connected. The impact head 43 is sleeved on the outside of the steel brazing ...

Embodiment 2

[0038] Example 2: Please refer to Figure 4 , Figure 7-Figure 10 , the specific embodiments of the present invention are as follows:

[0039] The blocking structure 423 includes a sliding structure 23a, a movable structure 23b, and an inner groove 23c. The sliding structure 23a is horizontally installed on the lower end of the movable structure 23b and is located on the same axis. The inner groove 23c runs through the inner side of the sliding structure 23a and is integrated. The movable structure 23b is sleeved on the outside of the steel brazing 421 and the inner groove 23c surrounds the steel brazing 421.

[0040] refer to Figure 7-Figure 8 The movable structure 23b includes a sliding seat b1, an installation groove b2, an inner chute b3, a support structure b4, and a dust outlet b5. The installation groove b2 is set inside the sliding seat b1 and is an integrated structure. The inner sliding The groove b3 is recessed in the inner side of the sliding seat b1 and slopes f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com