Jetting device for oil-shale drill hydraulic mining

A jet device and oil shale technology, applied in hydraulic mining, earth drilling, special mining, etc., can solve the problems of maintaining a single jet mode, single function of the jet device, and intermittent water flow pressure, etc., to improve adaptability and flexibility performance, improving mining efficiency, and stabilizing jet pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

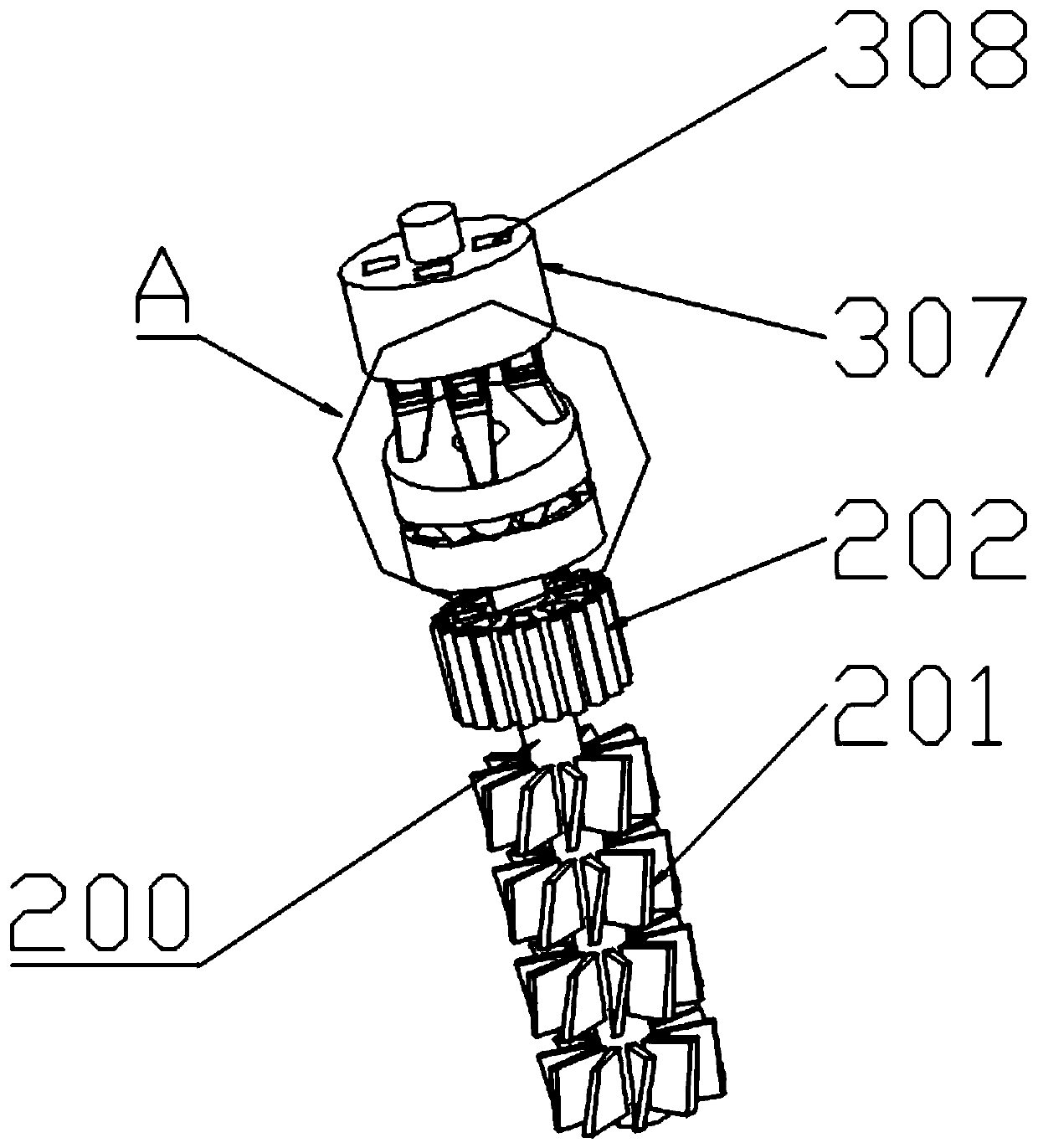

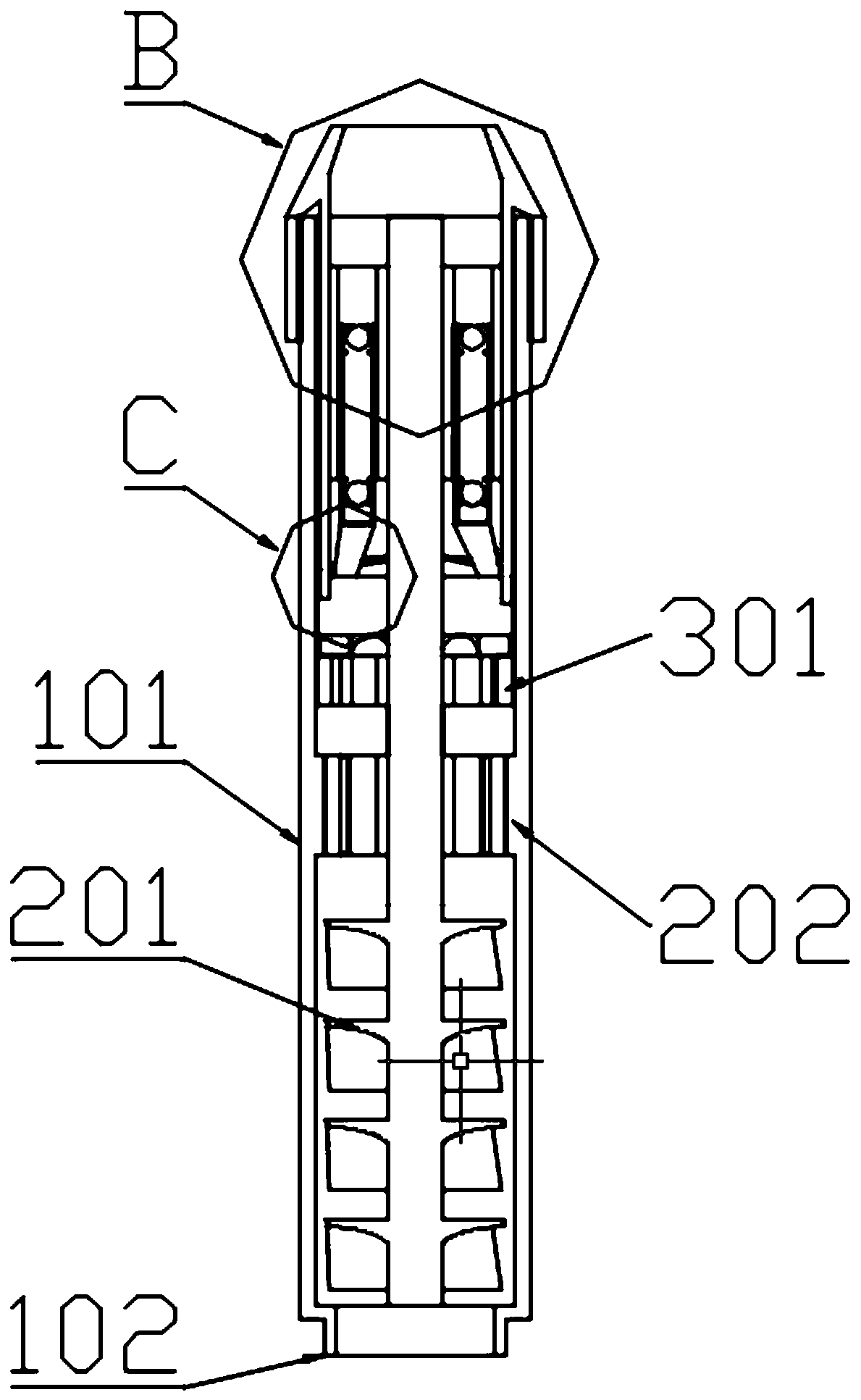

[0024] Example: such as Figure 1-8 As shown, a jet device for hydraulic drilling of oil shale, including a protection component, a booster component, a jet component, a one-way valve component, and an adjustment component. The protection component is located at the outermost side of the device to protect other components. Function, one end of the protection component is provided with a booster component, and the booster component plays the role of initially increasing the water pressure. The one-way valve assembly and the one-way valve assembly play the role of controlling the direction of water flow, and the protection assembly is provided with an adjustment assembly at the end away from the pressurization assembly, and the adjustment assembly plays the role of switching between ordinary jet flow and continuous high-pressure jet flow.

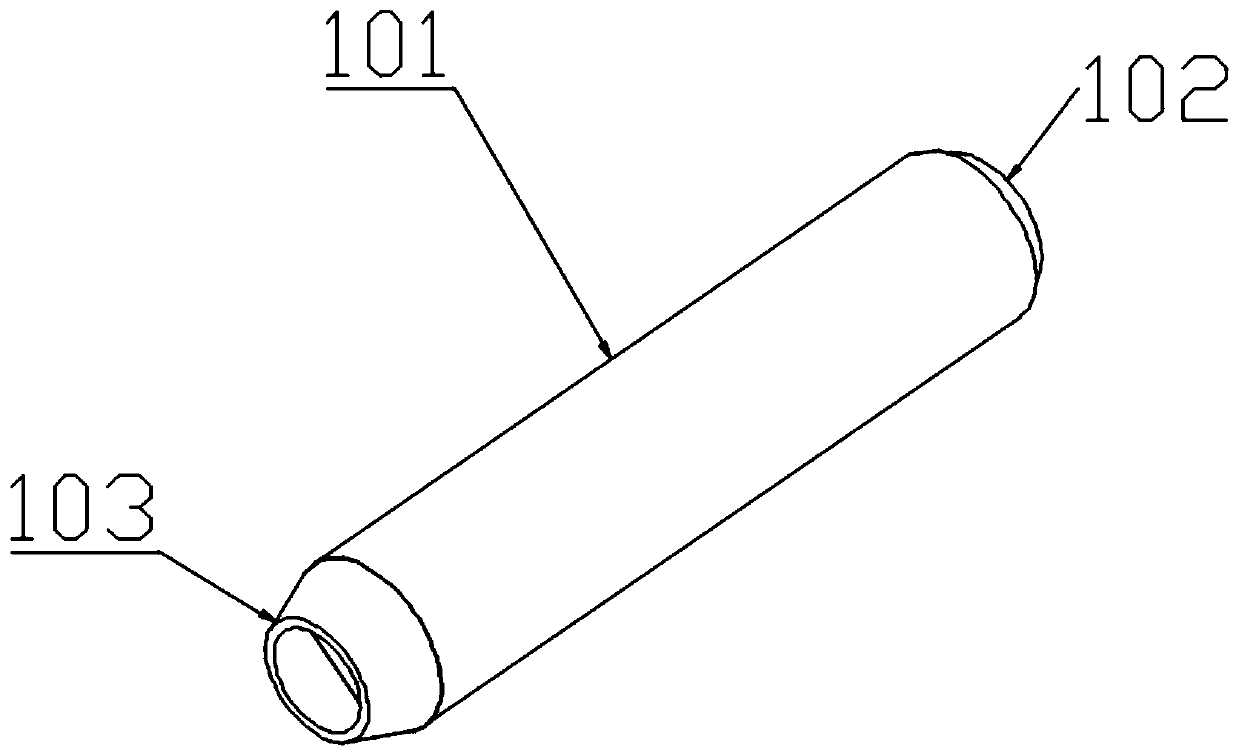

[0025] The protective assembly includes a sleeve 101, a pipe adapter 102, and a jet regulating head 103. The sleeve 101 is located at the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com