Civil engineering anti-seismic structure

An earthquake-resistant structure and civil engineering technology, applied in the field of earthquake-resistant civil engineering process, can solve the problems of lack of and inability to transport pipes and excellent seismic protection, and achieve the effect of realizing protection and improving protection capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

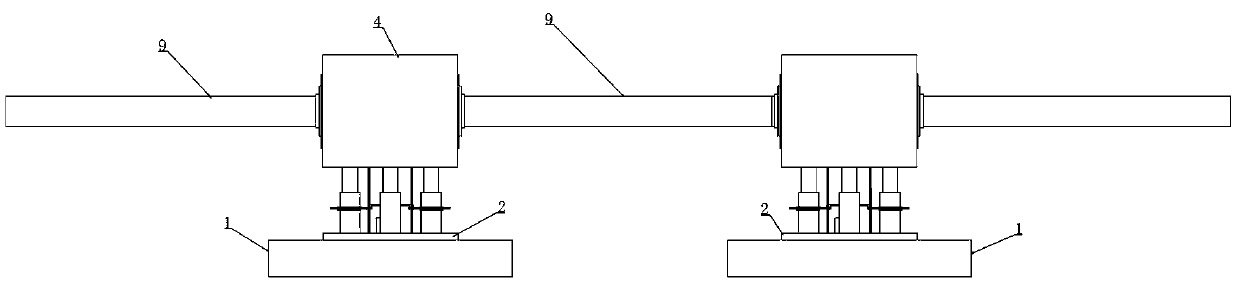

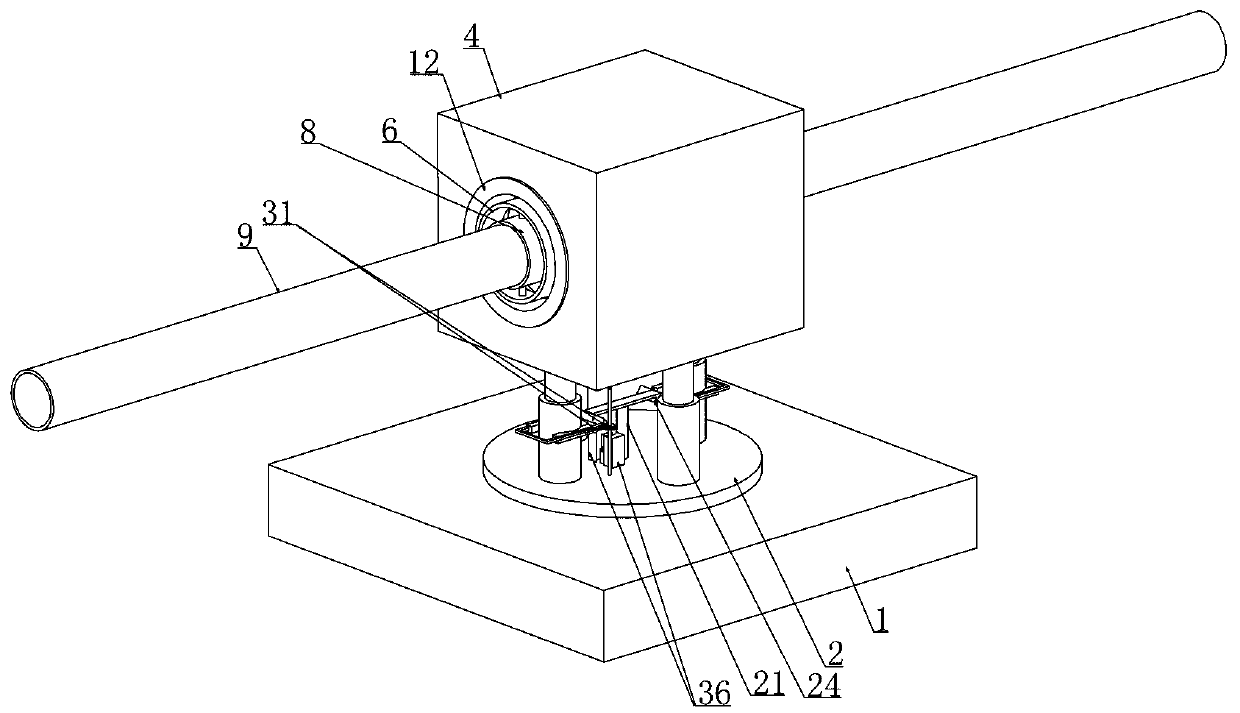

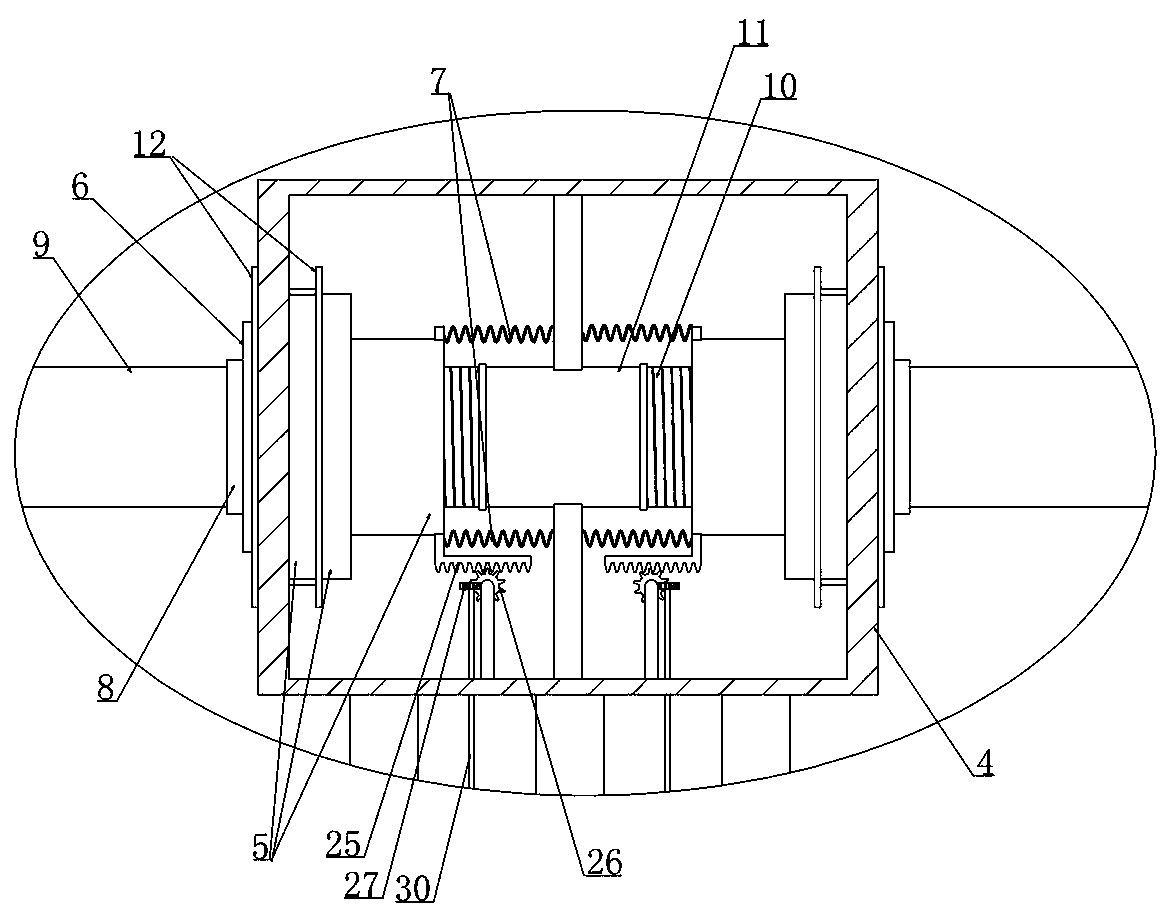

[0044] Embodiment 1, this embodiment provides a kind of civil engineering anti-seismic structure, refer to the attached figure 2 As shown, it includes a base plate 1, which is characterized in that a bearing plate 2 is installed longitudinally slidingly in the base plate 1, and a connection box 4 (the first spring 3 The settings are used to achieve the effect of buffering the connection box 4 when it is subjected to seismic longitudinal waves), refer to the attached image 3 As shown, the horizontal ends of the connection box 4 are respectively horizontally slidable and installed with a moving cylinder 5, referring to the attached Figure 6 As shown, the vertical adjustment ring 6 is installed on both sides of the longitudinal direction of the moving cylinder 5 and the second spring 7 is connected between the moving cylinder 5 and the connecting box 4 (when the moving cylinder 5 moves in the connecting box 4, the second spring is driven 7 stretching, so as to achieve a certa...

Embodiment 2

[0052] Embodiment 2, on the basis of embodiment 1, with reference to appended Figure 9 As shown, the carrier plate 2 is vertically slidably mounted on the bottom wall of the base plate 1 via the cylinder 19 integrally connected with it, and the bottom wall of the base plate 1 is fixedly installed with a slide rail 20 that is longitudinally slidable with the cylinder 19. 19 is coaxially arranged and vertically slidably installed on the locking column 21 of the cylinder 19, and a locking spring 22 is connected between the locking column 21 and the cylinder 19. The sliding rail 20 is provided with a locking hole 23 that matches the locking column 21 ;

[0053]Initially, when the annular baffle plate 12 at one end of the moving cylinder 5 in the connection box 4 does not touch the side wall of the connection box 4, the locking post 21 is inserted into the locking hole provided on the slide rail 20 under the action of the locking spring 22 In 23, the locking effect on the bearing...

Embodiment 3

[0054] Embodiment 3, on the basis of embodiment 1, with reference to appended Figure 7 As shown, the unlocking device includes an L-shaped rack 25 fixedly connected to the moving cylinder 5, and the L-shaped rack 25 is engaged with an unlocking gear 26, and the movement of the moving cylinder 5 synchronously drives the L-shaped rack 25 fixedly connected to it to move. , the L-shaped rack 25 drives the transmission device of the unlocking gear 26 through the unlocking gear 26 meshing with it, referring to the attached Figure 8 As shown, the transmission device of the unlocking gear 26 drives two triangular blocks 28 horizontally slidably mounted on the bearing plate 2 to move toward each other, and the triangular blocks 28 cooperate with the oblique blocks 24 to force the locking column 21 to move upwards, so that the moving cylinder 5. When the annular baffle plate 12 at one end of the connection box 4 touches the side wall of the connection box 4, the locking column 21 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com