Device and method for measuring surface accuracy of space compound cam for automatic tool changer

A technology of spatial compounding and automatic tool change, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low efficiency, inability to meet real-time online measurement, and high cost of three-coordinate machine measurement, and achieve accurate measurement and specialization High degree, efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

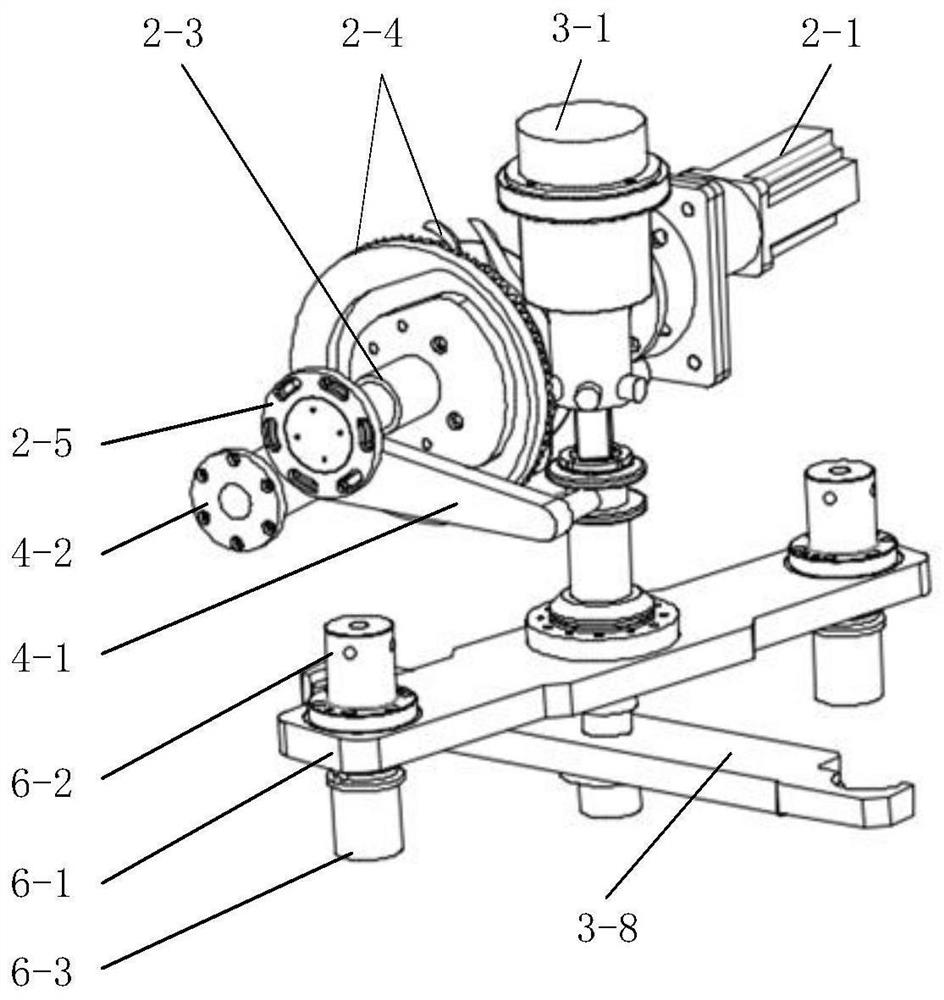

[0030] combine Figure 1-Figure 5 , the present invention firstly introduces the automatic tool changing device of the detection object, and the automatic tool changing device includes a frame, a space compound cam, a knife arm rotating device, and a rocker arm rotating device;

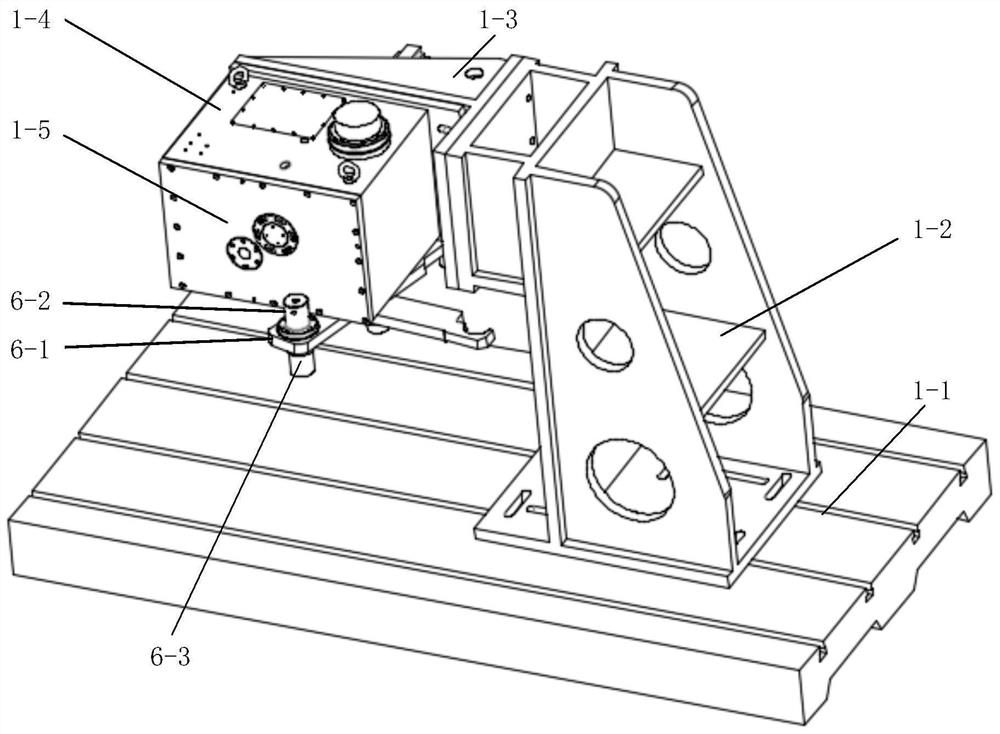

[0031] The frame includes a ground level iron 1-1, a base 1-2, an adapter frame 1-3, a body box 1-4, and a body box cover 1-5; the base 1-2 is fixed vertically on the ground level iron 1-1 ; The adapter frame 1-3 is vertically fixedly installed with the base 1-2; the body box 1-4 is vertically fixedly installed with the adapter frame 1-3, and the body box cover 1-5 is fixedly connected to the body box 1-4;

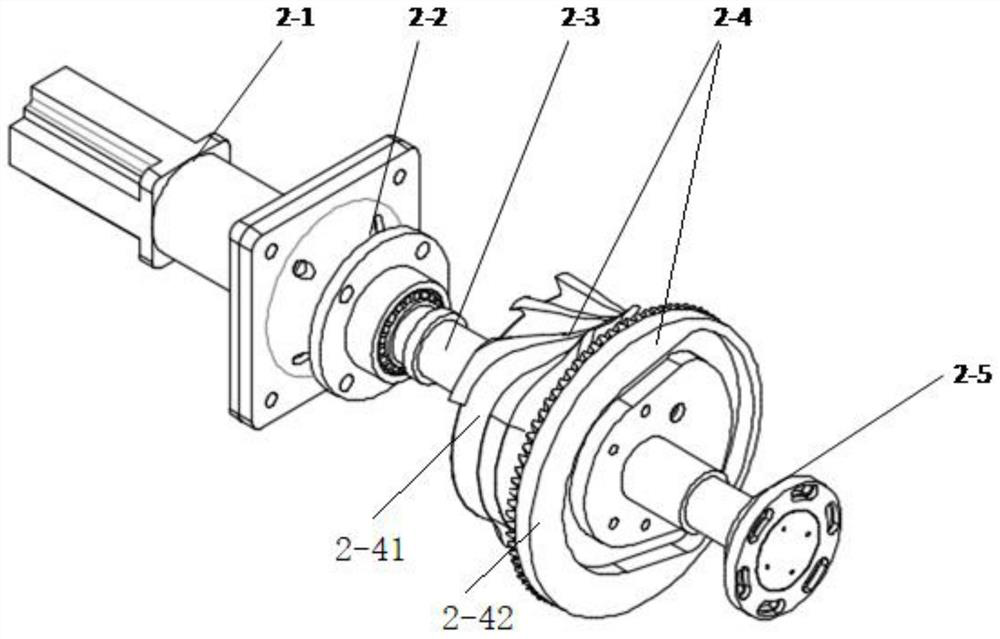

[0032] Described space compound cam comprises drive motor 2-1, fixed flange 2-2, drive shaft 2-3, space compound cam 2-4, drive shaft holder 2-5; Described drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com